Method for detecting silicon content in aluminum alloy

A detection method, the technology of aluminum alloy, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of long detection period, cumbersome detection process, high cost, etc., and achieve the effect of low cost, improved measurement range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

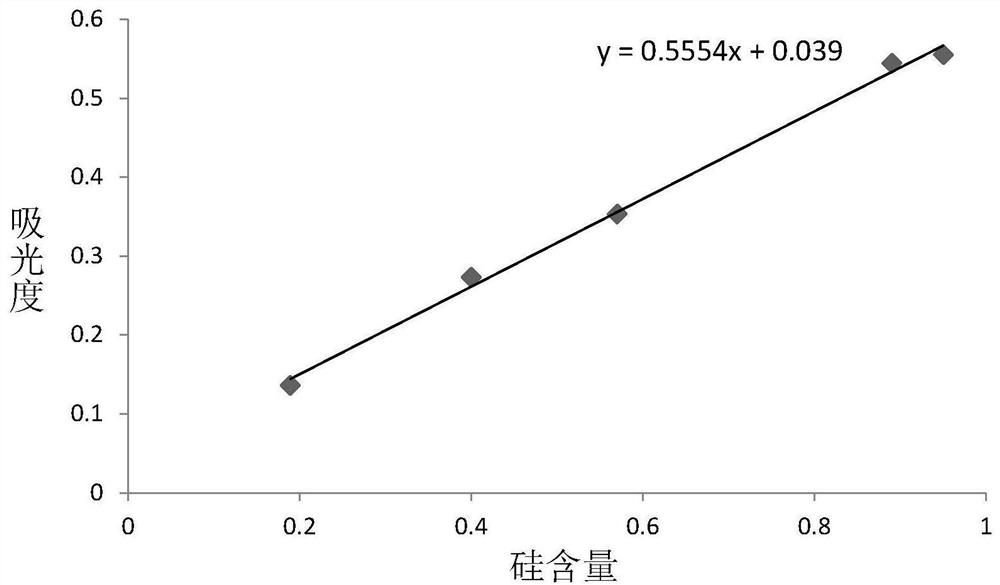

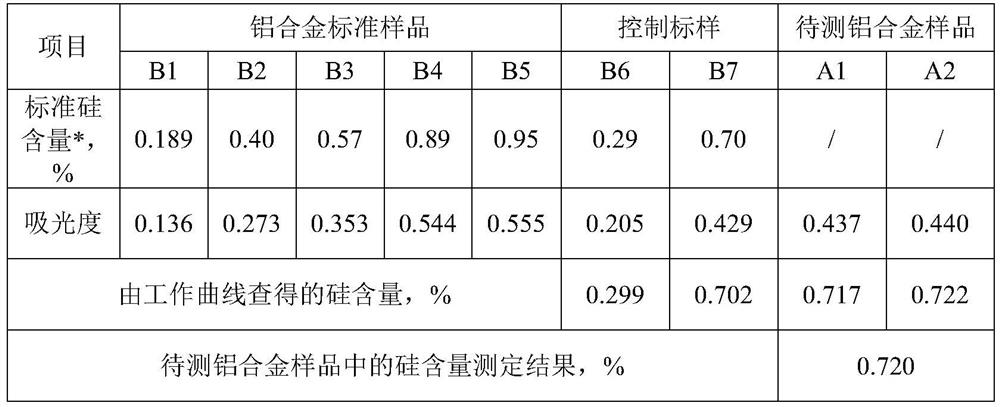

Image

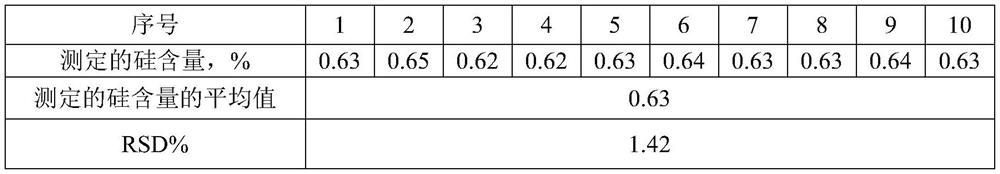

Examples

Embodiment 1

[0034] 1. Detection method:

[0035] (1) Weigh 0.5000g (accurate to 0.1mg) of the aluminum alloy sample, place it in a polytetrafluoroethylene beaker, add 20mL of sodium hydroxide solution with a concentration of 200g / L, and cover with a watch glass; , add 10 drops of hydrogen peroxide with ρ=1.10g / L dropwise, heat slowly and steam until the system becomes slurry, after cooling slightly, rinse the watch glass and the wall of the polyethylene beaker with water, add water to about 50mL, heat to near boiling, Let the soluble salts completely dissolve, and then cool slightly, add 35mL nitric acid solution (nitric acid 1+1), heat at about 70°C for about 2min (if MnO 2 To the precipitate, add a few drops of 5g / L sodium nitrite solution and boil until clear), cool; transfer the solution system into a 250mL measuring bottle, dilute with water, shake well, and constant volume to obtain the sample solution (mother solution);

[0036] Pipette 10mL of the above sample solution into a 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com