Production method of chemi-mechanical pulp and semi-chemical pulp

A technology of semi-chemical pulp and production method, which is applied in the field of pulp and paper making, can solve the problems of difficult extraction and utilization of hemicellulose and lignin, difficulty in extracting hemicellulose sugar, and low value, so as to make up for short fibers and reduce Effects of energy consumption and process cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for preparing plant material into colored mechanical pulp or semi-chemical pulp of the present invention comprises the following steps.

[0043] a) Material preparation: Wood raw materials are peeled, sliced, and extruded torn, and non-wood raw materials are removed from dust and silt, and cut into short lengths.

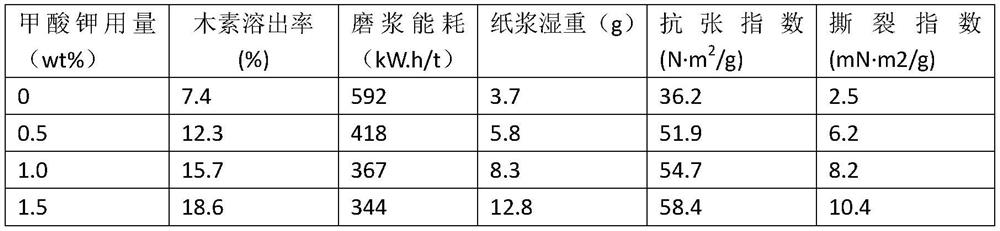

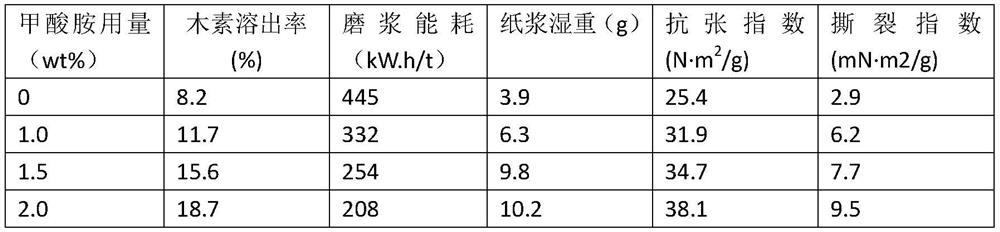

[0044] b) Softening: Put the plant material into a macerator, add formic acid / formate, and soak it at a certain temperature for a certain period of time to moisten and soften the plant material.

[0045] In a preferred version, the plant material is coniferous wood, such as masson pine, Korean pine, American black pine wood chips, the purpose is to produce chemical mechanical pulp, the solid-to-liquid ratio is 1:5, the concentration of formic acid is 70wt%, and the ammonium formate consumption is 0.5wt% of the plant material, the reaction temperature is 95°C, and the soaking time is 120min.

[0046] In a preferred version, the plant raw material i...

Embodiment 2

[0065] The bleaching of natural colored mechanical pulp or semi-chemical pulp, specifically, after the pulp is blended in step g), it is bleached. Single-stage bleaching or multi-stage bleaching can be performed.

[0066]In a preferred embodiment, chlorine dioxide is selected as the bleaching agent for single-stage bleaching, and the specific conditions are 12% pulp concentration, 2% chlorine dioxide, 70°C temperature, 2.5h time, and initial pH 4.0 (using sodium hydroxide or Sulfuric acid to adjust pH), under this condition, the brightness of larch softwood pulp reaches 54% ISO, the brightness of poplar hardwood pulp reaches 58% ISO, and the brightness of wheat straw pulp reaches 55% ISO. In a preferred embodiment, the bleaching agent used in multistage bleaching is chlorine dioxide, oxygen and hydrogen peroxide, specifically oxygen delignification (O), chlorine dioxide bleaching (D), hydrogen peroxide bleaching (P), The multi-stage combination of alkali extraction (E), the w...

Embodiment 3

[0068] Recycling technology of chemical-mechanical pulp or semi-chemical pulp waste liquid. The specific scheme of this technology is as follows:

[0069] a) Mix all contained waste liquids, including refining waste liquids and washing waste liquids, and remove fiber suspensions in the mixed liquids through a screen whose mesh number is higher than 80.

[0070] b) evaporating and concentrating the mixed solution, and condensing the steam to obtain condensate and residue. The condensate is an aqueous formic acid solution, and the residue is a mixture of lignin and hemicellulose sugars.

[0071] In a preferred solution, step b) concentrates the mixed solution by evaporation under reduced pressure, the absolute pressure is 80.0kPa, the evaporation temperature is 72°C, and the solid content is controlled between 60-65wt%.

[0072] c) The residue is stirred with water, then put into a filter bag and dehydrated by centrifugation or extrusion to obtain a filtrate and a filter residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com