Zirconium-based bulk amorphous alloy and preparation method thereof

An amorphous alloy and bulk technology, which is applied in the field of zirconium-based bulk amorphous alloy and its preparation, can solve the problems of limiting the application of amorphous alloy, changing the properties of amorphous alloy, and limiting plastic deformation ability at room temperature, and achieves good application. Potential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a method for preparing a zirconium-based bulk amorphous alloy described in the above technical solution, comprising the following steps:

[0029] mixing metal raw materials corresponding to the zirconium-based bulk amorphous alloy, and melting to obtain a master alloy ingot;

[0030] A water-cooled copper mold is used to suction-cast the master alloy ingot to obtain a zirconium-based bulk amorphous alloy.

[0031] According to the invention, metal raw materials corresponding to the zirconium-based bulk amorphous alloy are mixed and smelted to obtain master alloy ingots. The present invention has no special limitation on the mixing process, and the mixing can be carried out according to the well-known process in the art.

[0032] In the present invention, the smelting is preferably carried out in a non-consumable arc smelting furnace. Before the smelting, the vacuum of the cavity of the non-consumable arc smelting furnace is preferably eva...

Embodiment 1

[0041] Preparation of Zr 60 Cu 25 Al 10 Fe 4 Ag 1 (X=1) bulk amorphous alloy, the specific atomic percentage is shown in Table 1:

[0042] will be composed of Zr 60 Cu 25 Al 10 Fe 4 Ag 1 The alloy is proportioned according to the atomic ratio converted into the weight ratio. The total mass of the prepared raw materials is 30g, and the metallic materials zirconium, copper, aluminum, iron and granular silver in the shape of filaments (cut into short wires with a length of 10mm) are weighed respectively. Re-batching, mixing the prepared raw materials into the copper crucible of the non-consumable arc melting furnace, and pumping the vacuum degree of the non-consumable arc melting furnace cavity to 6×10 -3 Below Pa, fill with argon until the cavity pressure is 0.45MPa, and then smelt the titanium block to absorb the residual oxygen in the environment;

[0043] Under the protection of argon (the pressure of the argon protective atmosphere is 0.45MPa), the 30g raw material...

Embodiment 2

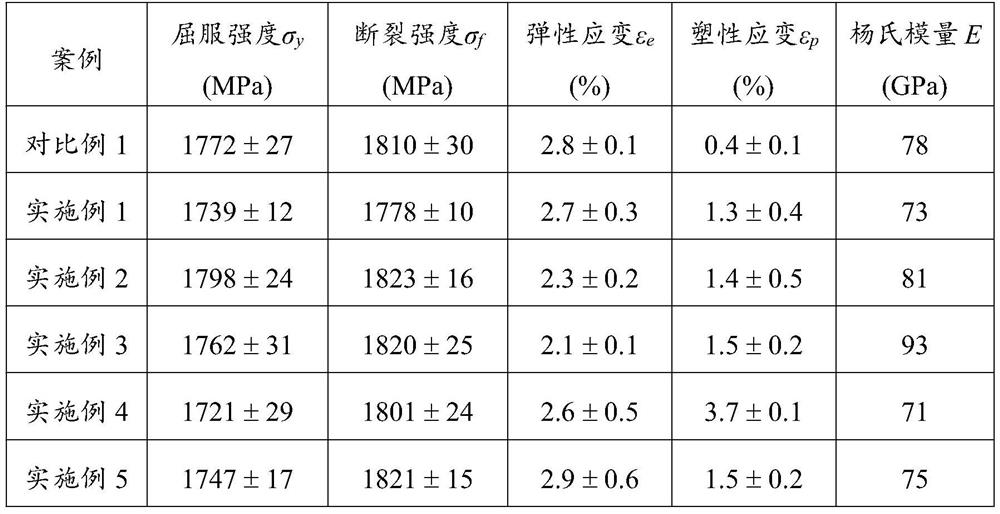

[0047] The difference with Example 1 is: the preparation of Zr 60 Cu 25 Al 10 Fe 3 Ag 2 (X=2) bulk amorphous alloy, the others are the same as in Example 1, and the specific atomic percentages are shown in Table 1. figure 1 Zr is shown in 60 Cu 25 Al 10 Fe 3 Ag 2 (X=2) An amorphous alloy with a critical diameter of alloy composition of 8mm. The experimental data in this embodiment given in Table 2 and Table 3 are all obtained from the experimental results of an amorphous cast rod with a diameter of 8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| plastic strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com