A kind of method that titanium-aluminum polymer precursor prepares aluminum titanate ceramic fiber

A ceramic fiber and polymer technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of poor fiber performance, high energy consumption of solid-phase method, high fiber porosity, and achieve good thermal shock resistance and easy batch production. The effect of chemical production and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

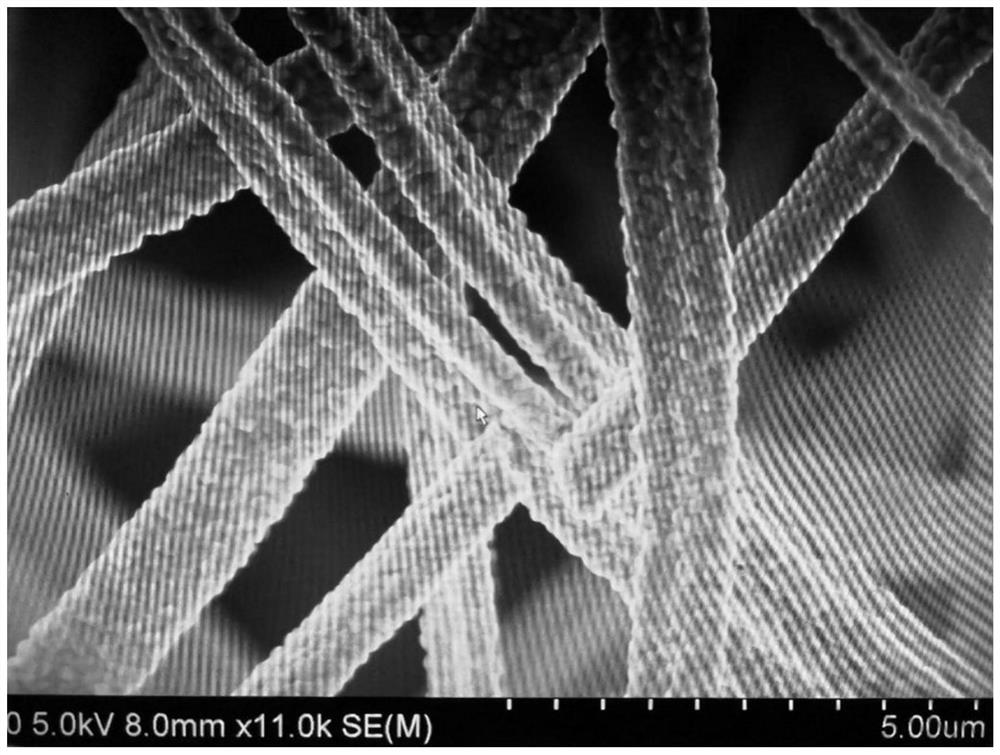

Image

Examples

Embodiment 1

[0051] A method for preparing aluminum titanate fibers using titanium-aluminum polymer as a precursor, comprising the following preparation steps:

[0052] (1) According to the molar ratio of titanium tetrachloride: anhydrous aluminum chloride: distilled water: acetylacetone: triethylamine=1:2:3:3:10, take by weighing 20g titanium tetrachloride, 28g anhydrous chlorine Aluminum chloride, 5.7g distilled water, 32g acetylacetone and 106g triethylamine, and respectively diluted in 40g, 140g, 2.85g with 1:2, 1:5, 1:0.5, 1:1 and 1:1 and mass ratio , 32g and 106g in five parts of anhydrous methanol, under ice bath conditions, add anhydrous aluminum chloride methanol solution to the stirring titanium tetrachloride methanol solution, continue stirring for 30min after adding and keep the ice bath, Obtain solution A, then add distilled water, acetylacetone and triethylamine methanol solution dropwise to the mixed solution A, and continue to stir under ice bath for 12 hours to fully react...

Embodiment 2

[0058] As described in Example 1, the method for preparing aluminum titanate fibers using titanium-aluminum polymer as a precursor, the difference is that

[0059] In step (1), the methanol solution of anhydrous aluminum chloride is added to the methanol solution of titanium tetrachloride instead of the methanol solution of titanium tetrachloride added to the methanol solution of anhydrous aluminum chloride, and the obtained fiber is the same as that of Example 1 The fibers obtained were virtually indistinguishable.

Embodiment 3

[0061] As described in Example 1, the method for preparing aluminum titanate fibers using titanium-aluminum polymer as a precursor, the difference is that

[0062] In step (2), change the mass ratio of titanium-aluminum polymer precursor: anhydrous methanol: PEO to 100:100:1, that is, dissolve 5g titanium-aluminum polymer precursor and 0.05g PEO in 5g anhydrous methanol Among them, the obtained fiber diameter is larger, the fiber diameter is about 1 μm, and the yield is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com