Preparing method for as-cast-condition mixed matrix QT500-14 spheroidal graphite cast iron

A ductile iron and matrix technology, which is applied in the field of preparation of as-cast mixed matrix QT500-14 ductile iron, can solve the problems of long melt processing process, unstable elongation of the attached cast test block, and complicated operation, and achieves the promotion of magnesium absorption. rate, good spheroidization effect, and the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention provides a method for preparing a mixed matrix QT500-14 cast ductile iron, comprising the steps of:

[0037] Sl, raw material input mass percentage is as follows: iron: 60 ~ 80%, scrap: 5 to 20%, return scrap: 5 to 20% of electrolytic copper plate: 0.1 to 0.2%, of pure nickel plate: 0.3 to 0.4%. In particular, the use of pig iron Q10 ductile iron pig iron, comprising the following mass percent composition: C: 4.3 ~ 4.5%, Si: 0.8 ~ 0.9%, Mn <0.1%, P <0.04%, S <0.02%; the scrap quality carbon steel scrap, comprising the following mass percent composition: C: 0.1 ~ 0.15%, Si: 0.2 ~ 0.4%, Mn: 1 ~ 1.3%, P <0.03%, S <0.02%. Pig iron and steel scrap prior to use after blasting treatment required surface rust and other impurities.

[0038] S2, molten iron smelting: first package added in the molten scrap, pig iron and return scrap, to be added to the electrolytic copper sheet after scrap, pig iron and return scrap completely melted, the temperature control in ...

Embodiment 2

[0047] Example 2 relates to a method of preparing a mixed matrix QT500-14 ductile cast, this embodiment differs from embodiment 1 in that the embodiment: Example 2 mass% of Cu element in the embodiment of the control range of 0.05 to 0.1%. The present embodiment, after the end of the ball of the reaction, the sample is detected, the control ball after molten iron components: C: 3.5 ~ 3.8%, Si: 2.5 ~ 2.8%, Mn <0.3%, Cu: 0.05 ~ 0.1%, Ni: 0.3 ~ 0.4%, P <0.02%, S <0.02%, Mg: 0.04 ~ 0.07%, Re: 0.01 ~ 0.02%, the balance being Fe and unavoidable impurities.

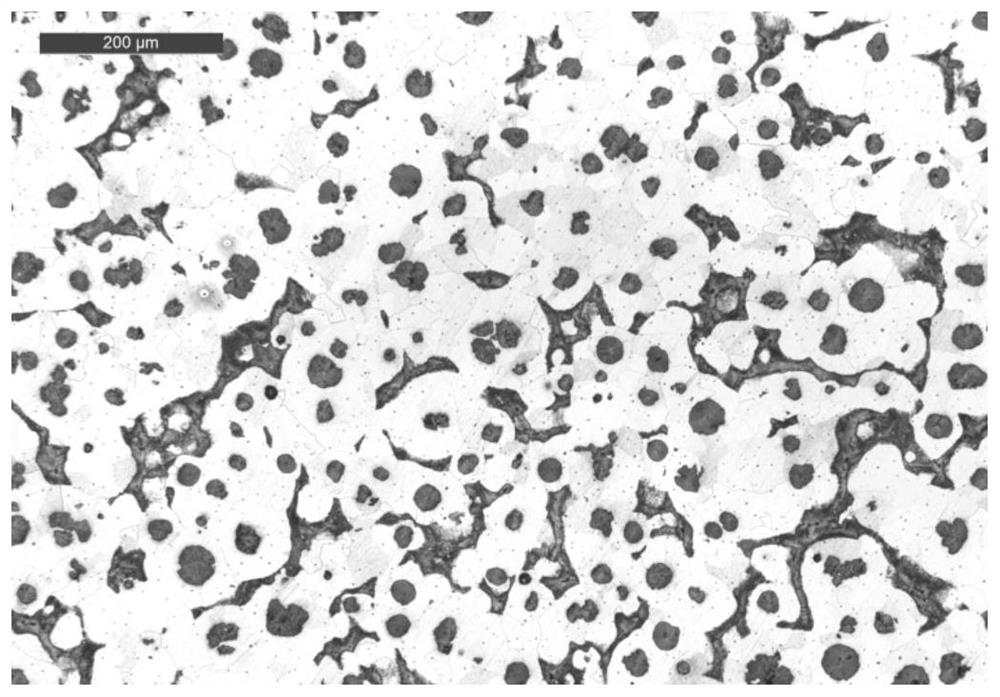

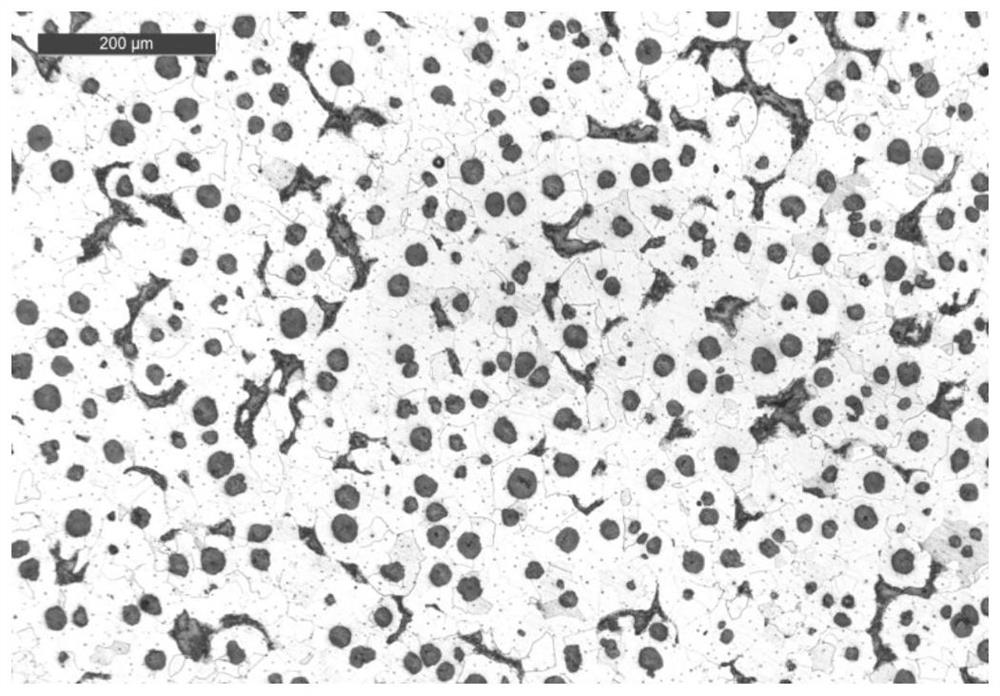

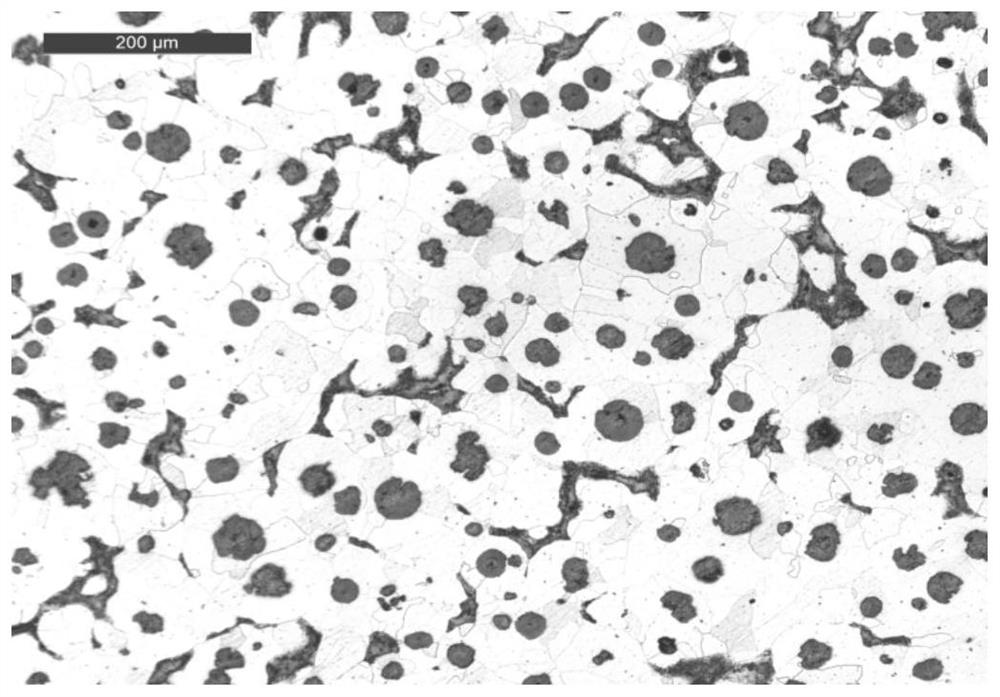

[0048] Single cast test piece prepared above chemical analysis results shown in Table 1, cast metallographic examination of Table 2, binding figure 2 Understood that ball at Level 2, the size of the graphite balls 7 (viewed under 100 ×, graphite length> 1.5 ~ 3mm), spheroidization ratio ≥90% pearlite matrix 5 to 15% ferrite 75 to 90%. Preparation when the present embodiment is one kind of cast ductile iron mix matrix QT500-14 perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com