Method for preparing cornus officinalis extract, application in cigarettes and cigarette

A technology of Cornus officinalis and its extracts, which is applied in the field of preparation of Cornus officinalis extracts, can solve the problems that there are no related reports on the application of cigarettes, and achieve the effects of rich smoke, improved aftertaste and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

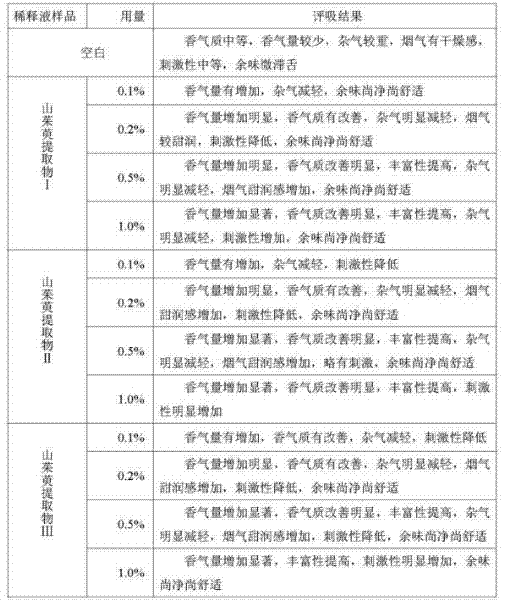

Examples

preparation example Construction

[0023] In one embodiment, the preparation method of Cornus officinalis extract comprises the following steps: 1) Ultrasonic-microwave synergistic extraction: dry Cornus officinalis powder with a particle size of 150-420 μm and 50 wt % ~80 wt% ethanol solution is put into the cavity of ultrasonic-microwave synergistic extraction equipment for extraction; after the extraction is completed, cool down, use a 150-200 mesh screen to filter the extract to obtain a filtrate, and concentrate the filtrate to obtain a concentrate; 2 ) centrifugation: dissolving the concentrated solution in water with 2 to 3 times the mass of the concentrated solution, and centrifuging to obtain a supernatant; 3) column chromatography: passing the supernatant through a chromatographic column, first using 10wt% to 30 wt% ethanol or water for 2 to 6 times the column volume to elute impurities, and then 50 wt% to 70 wt% ethanol for 2 to 6 times the column volume to elute and collect the eluate; 4) Concentrati...

Embodiment 1

[0033] Accurately weigh 200g of Cornus officinalis, dry at 45°C, and crush it to a coarse powder with a particle size of 250μm, add 1.6kg of ethanol solution with a concentration of 70%, and conduct ultrasonic-microwave collaborative extraction for 15min, with ultrasonic power 50W, microwave power 300W, constant temperature 55 ℃, the extract was filtered through a 200-mesh sieve, and concentrated under reduced pressure until the relative density was 1.12 at 25°C to obtain a concentrated solution; the concentrated solution was dissolved in water with twice the quality of the concentrated solution, and centrifuged at a centrifugal speed of 4000rpm for 20 minutes to obtain Supernatant: The supernatant is dynamically adsorbed by polyamide resin, and the adsorption and deflow rate is 1BV / h. After adding the sample, first use 5 times the column volume of 20% ethanol to elute the impurities, and then use 4 times the column volume of 70% ethanol to elute the impurities. % ethanol eluti...

Embodiment 2

[0035]Accurately weigh 200g of Cornus officinalis, dry at 50°C, and crush it to a coarse powder with a particle size of 420μm, add 1.2kg of 50% ethanol solution, ultrasonic-microwave collaborative extraction for 25min, ultrasonic power 50W, microwave power 250W, constant temperature 60 ℃, the extract was filtered through a 200-mesh sieve, and concentrated under reduced pressure until the relative density was 1.15 at 25°C to obtain a concentrated solution; the concentrated solution was dissolved in water twice the quality of the concentrated solution, and centrifuged at a centrifugal speed of 6000rpm for 10 minutes to obtain Supernatant: the supernatant is dynamically adsorbed by AB-8 macroporous adsorption resin, the adsorption flow rate is 0.5BV / h, after the sample is loaded, first use 5 times the column volume of 20% ethanol to elute the impurities, and then use 4 times the column volume The volume of 80% ethanol was eluted, and the eluate was collected. The amount of AB-8 ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com