Preparation method of Se-C positive electrode composite material of lithium-selenium battery

A composite material and battery technology, applied in the field of electrochemical batteries, can solve the problems of complex preparation method of nano-carbon materials, poor overall cycle performance, long composite time, etc., to reduce self-discharge and polysulfide ion shuttle effect, The effect of high practical value and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

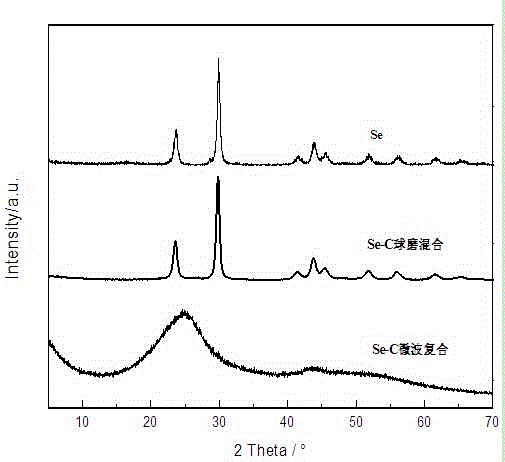

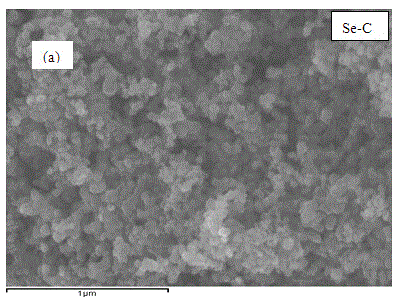

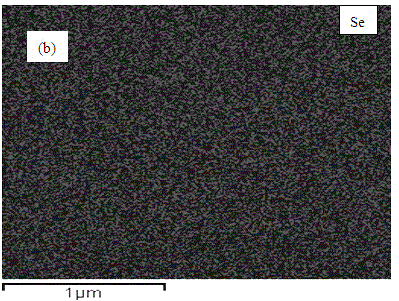

[0029] Weigh 2.1g of selenium powder and 0.9g of Ketjen black respectively, and ball mill for 2 hours at a speed of 400r / min on a ball mill to obtain a uniformly mixed Se-C mixed powder. Then put the ball-milled Se-C mixed powder into a microwave oven, and then introduce argon gas after vacuuming. The heating rate is 10°C / min, and it is kept at 400°C for 1h. The microwave output power is 1.0kW, and the selenium content is obtained. 55.68wt% Se-C microwave composite. Using N-methylpyrrolidone as solvent, the prepared Se-C microwave composite material was slurried with acetylene black and PVDF at a mass ratio of 7:1:2. Finally, the adjusted slurry was evenly coated on the aluminum foil, and placed in a vacuum drying oven at 60° C. for 12 hours. figure 1 It is the XRD pattern of the obtained sample. It can be seen from the figure that after microwave thermal compounding, the compound is in an amorphous state, and all the characteristic peaks of Se disappear, indicating that Se i...

Embodiment 2

[0031] Weigh 2.4g of selenium powder and 0.6g of acetylene black respectively, and ball mill for 4 hours at a speed of 500r / min in a ball mill to obtain a uniformly mixed Se-C mixed powder. Then put the ball-milled Se-C mixed powder in a microwave oven, and after vacuuming, argon gas is introduced. The heating rate is 15°C / min, and it is kept at 300°C for 50min. The microwave output power is 0.8kW, and the selenium content is obtained. 61.32wt% Se-C microwave composite. Using deionized water as a solvent, the prepared Se-C microwave composite material was slurried with Ketjen black conductive carbon black and LA133 at a mass ratio of 7:2:1. Finally, the adjusted slurry was evenly coated on the aluminum foil, and placed in a vacuum drying oven at 70° C. for 10 h. The material is used as the positive electrode, and the metal lithium sheet is used as the negative electrode to assemble a button-type simulated battery. According to the electrical performance test, its capacity can...

Embodiment 3

[0033]Weigh 1.8g of selenium powder and 1.2g of BP2000 conductive carbon black respectively, and ball mill them on a ball mill at a speed of 300r / min for 5h to obtain a uniformly mixed Se-C mixed powder. Then put the ball-milled Se-C mixed powder in a microwave oven, vacuumize it and feed it with nitrogen. The heating rate is 25°C / min, and it is kept at 350°C for 40min. The microwave output power is 0.9kW, and the selenium content is 48.96wt. % of Se-C microwave composites. Using N-methylpyrrolidone as a solvent, the prepared Se-C microwave composite material, BP2000 conductive carbon black and PVDF were slurried at a mass ratio of 7:1.5:1.5. Finally, the adjusted slurry was evenly coated on the aluminum foil, and placed in a vacuum drying oven at 80°C for 8 hours. The material is used as the positive electrode, and the metal lithium sheet is used as the negative electrode to assemble a button-type simulated battery. According to the electrical performance test, the capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com