A drug-loaded thermochromic hydrogel functionalized fabric and its preparation and application

A thermochromic and hydrogel technology, which is applied in textiles and papermaking, medical preparations of non-active ingredients, physical treatment, etc., can solve the problem of expensive equipment required for drug content, and achieve the effect of preventing breakage and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

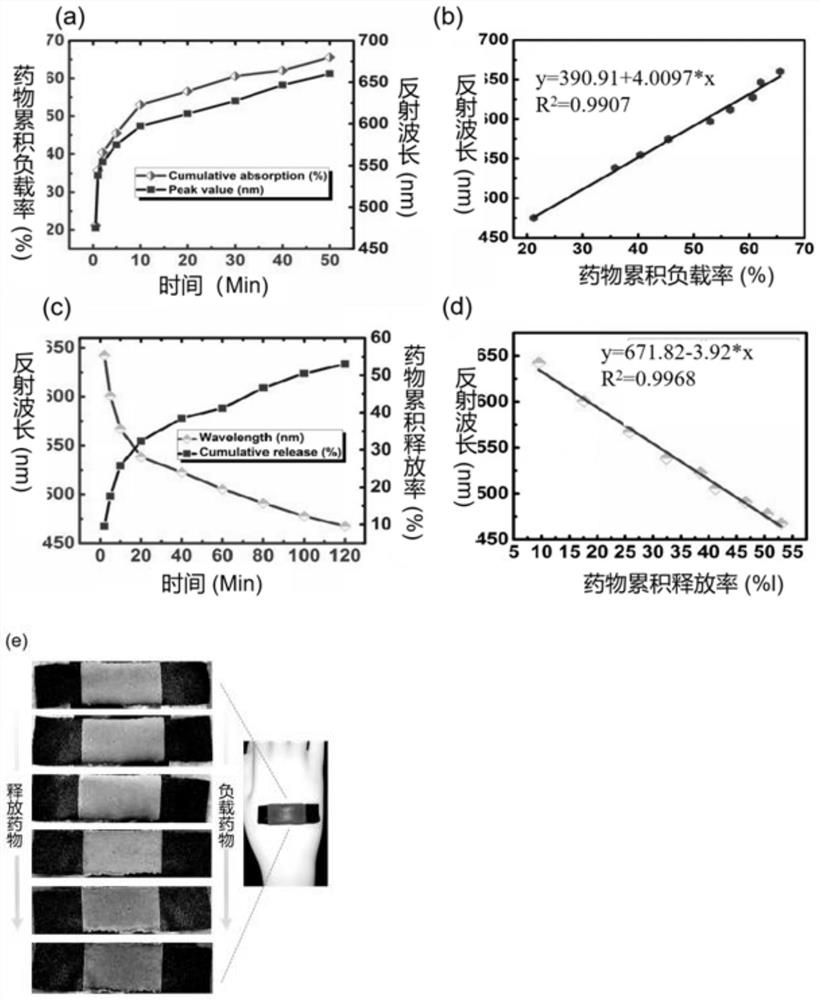

Embodiment 1

[0044] Add 0.3g of ferrocene into 60ml of acetone, ultrasonically dissolve it for 5 minutes, then add dropwise 1ml of 30% hydrogen peroxide and stir for 2 hours. After stirring evenly, move it into a 100ml hydrothermal kettle, react at 180°C for 48h, take it out and cool it to room temperature. The obtained product was subjected to magnetic deposition with a magnet with a magnetic field strength of 0.2T, and then redissolved with acetone, and the magnetic deposition was continued for 3 times. Obtained Fe 3 o 4 @C Magnetic particles (180nm) were redispersed in ethylene glycol (21mg / ml). Then add 2g NIPAM, 100 μl AAc, 20 mg BIS in 3 ml ethanol / ethylene glycol (1:1) and sonicate until completely dissolved, then add 11 μL HMPP and finally, 200 μL Fe 3 o 4 @C Magnetic particle ethylene glycol dispersion (20mg / ml) was added to the above prepolymer solution (600μL), and ultrasonically mixed for 10min. Subsequently, the polyester fabric (6*2cm) was subjected to oxygen plasma trea...

Embodiment 2

[0046] Add 0.4g of ferrocene into 60ml of acetone, ultrasonically dissolve it for 5 minutes, then add 2ml of 30% hydrogen peroxide dropwise and stir for 2 hours. After stirring evenly, transfer it into a 100ml hydrothermal kettle, react at 190°C for 64h, take it out and cool it to room temperature. The obtained product was subjected to magnetic deposition with a magnet having a magnetic field strength of 0.3 T, and then redissolved with acetone, and the magnetic deposition was continued for 3 times. Obtained Fe 3 o 4 @C Magnetic particles (240nm) were redispersed in ethylene glycol (30mg / ml). Then add 2g NIPAM, 200 μl AAc, 30 mg BIS in 3 ml ethanol / ethylene glycol (1:1) and sonicate until completely dissolved, then add 15 μL HMPP and finally, 300 μL Fe 3 o 4 @C Magnetic particle ethylene glycol dispersion (30mg / ml) was added to the above prepolymer solution (900μL), and ultrasonically mixed for 10min. Subsequently, the polyester fabric (6*2cm) was subjected to oxygen plas...

Embodiment 3

[0048] Add 0.5g of ferrocene into 60ml of acetone, dissolve it by ultrasonication for 5 minutes, then add 2ml of 30% hydrogen peroxide dropwise and stir for 2 hours. room temperature. The obtained product was subjected to magnetic deposition with a magnet with a magnetic field strength of 0.4T, and then redissolved with acetone, and the magnetic deposition was continued for 3 times. Obtained Fe 3 o 4 @C Magnetic particles (300nm) were redispersed in ethylene glycol (40mg / ml). Then add 2g NIPAM, 400 μl AAc, 40 mg BIS in 3 ml ethanol / ethylene glycol (1:1) and sonicate until completely dissolved, then add 20 μL HMPP and finally, 400 μL Fe 3 o 4 @C Magnetic particle ethylene glycol dispersion (40mg / ml) was added to the above prepolymer solution (1200μL), and ultrasonically mixed for 10min. Subsequently, the polyester fabric (6*2cm) was subjected to oxygen plasma treatment to make the surface hydrophilic (parameters were set to 300W, 1min), and then the treated polyester fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com