Rare earth hafnate high-entropy ceramic powder through low-temperature synthesis and preparation method

A technology of ceramic powder and rare earth nitrate, which is applied in the field of low-temperature synthesis of rare earth hafnate high-entropy ceramic powder and its preparation, can solve the problems of high calcination and sintering temperature, complex process, and long holding time, and achieve low synthesis temperature , simple operation and fast preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

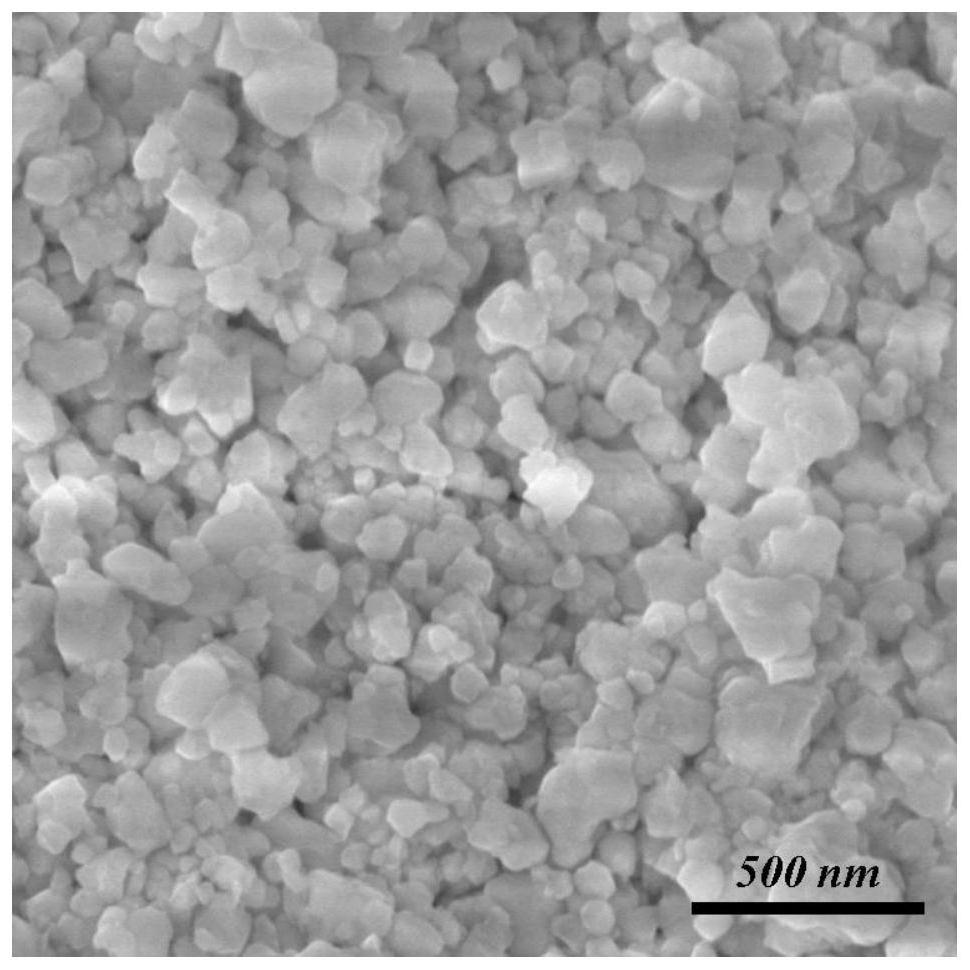

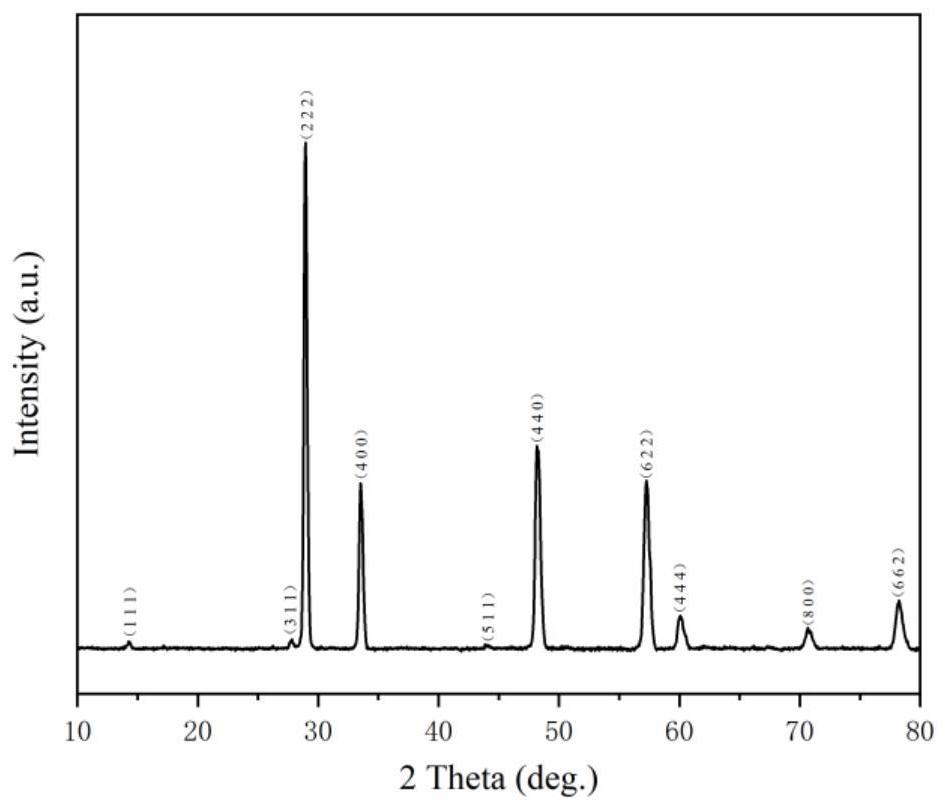

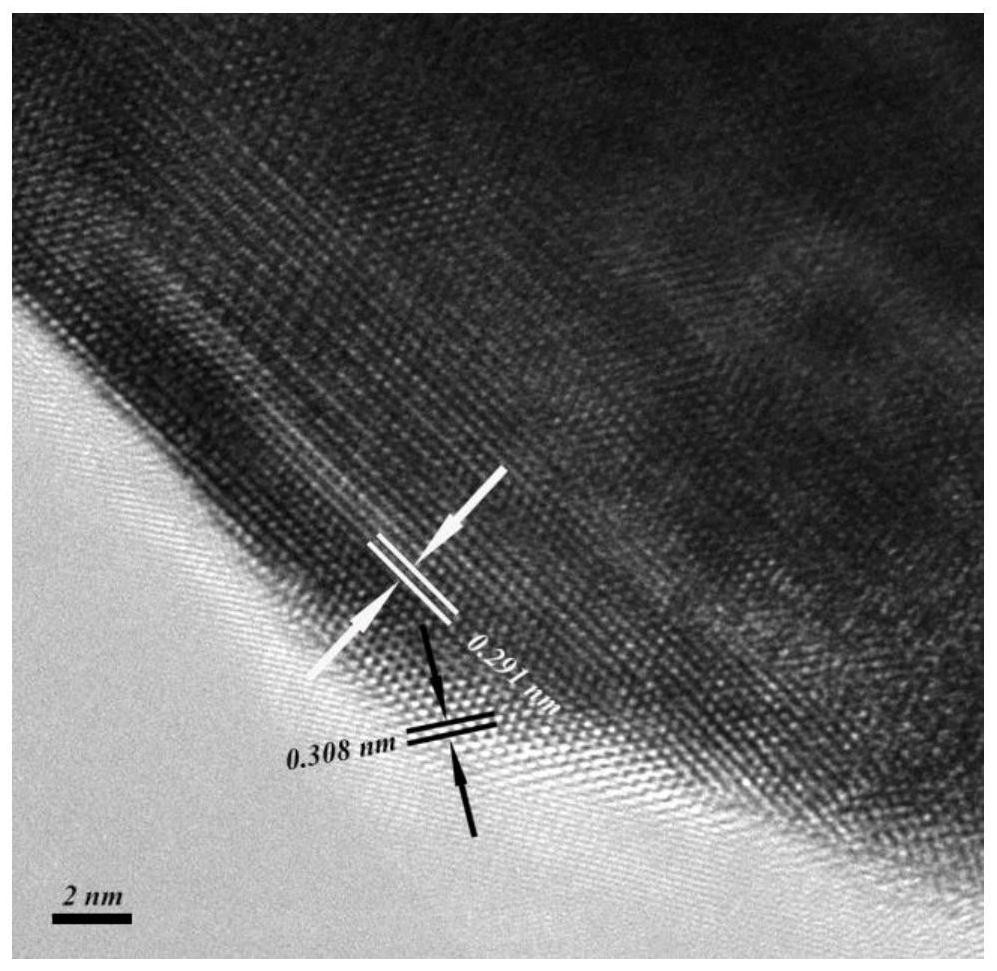

[0030] This embodiment adopts combustion method to prepare rare earth hafnate high-entropy ceramics ((La 0.2 Ce 0.2 PR 0.2 SM 0.2 Eu 0.2 ) 2 f 2 o 7 ) powder.

[0031] Step 1: Weigh a certain amount of hafnium tetrachloride powder and dissolve it in deionized water, and stir it thoroughly; drop excess ammonia water into the solution, and react for half an hour to obtain a white flocculent precipitate; repeat the obtained white precipitate Stand and wash for 4 to 5 times, then place the beaker containing the white precipitate in a water bath constant temperature magnetic stirrer at a temperature of 50 to 80°C, add excess concentrated nitric acid, and stir while heating until a clear solution is obtained.

[0032] Step 2: In the obtained solution, add hydrated lanthanum nitrate (La(NO 3 ) 3 ·xH 2 O), hexahydrate cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), Liuhe water praseodymium nitrate (Pr(NO 3 ) 3 ·6H 2 O), samarium nitrate (Sm(NO 3 ) 3 ·6H 2 O) and europium nitr...

Embodiment 2

[0035] This embodiment adopts combustion method to prepare rare earth hafnate high-entropy ceramics ((La 0.2 Nd 0.2 PR 0.2 SM 0.2 Eu 0.2 ) 2 f 2 o 7 ) powder.

[0036] Step 1: Weigh a certain amount of hafnium tetrachloride powder and dissolve it in deionized water, and stir it thoroughly; drop excess ammonia water into the solution, and react for half an hour to obtain a white flocculent precipitate; repeat the obtained white precipitate Stand and wash for 4 to 5 times, then place the beaker containing the white precipitate in a water bath constant temperature magnetic stirrer at a temperature of 50 to 80°C, add excess concentrated nitric acid, and stir while heating until a clear solution is obtained.

[0037] Step 2: in the obtained solution, add hexahydrate lanthanum nitrate (La(NO) containing the same mol ratio of rare earth element 3 ) 3 ·6H 2 O), rubidium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), Liuhe water praseodymium nitrate (Pr(NO 3 ) 3 ·6H 2 O), s...

Embodiment 3

[0040] This embodiment adopts combustion method to prepare rare earth hafnate high-entropy ceramics ((La 0.2 Ce 0.2 Nd 0.2 SM 0.2 Eu 0.2 ) 2 f 2 o 7 ) powder.

[0041] Step 1: Weigh a certain amount of hafnium tetrachloride powder and dissolve it in deionized water, and stir it thoroughly; drop excess ammonia water into the solution, and react for half an hour to obtain a white flocculent precipitate; repeat the obtained white precipitate Stand and wash for 4 to 5 times, then place the beaker containing the white precipitate in a water bath constant temperature magnetic stirrer at a temperature of 50 to 80°C, add excess concentrated nitric acid, and stir while heating until a clear solution is obtained.

[0042] Step 2: In the obtained solution, add hydrated lanthanum nitrate (La(NO 3 ) 3 ·xH 2 O), hexahydrate cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), rubidium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), samarium nitrate (Sm(NO 3 ) 3 ·6H 2 O) and europium nitrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com