A method for synthesizing high-performance barium ferrite with molten salt as flux and reaction medium

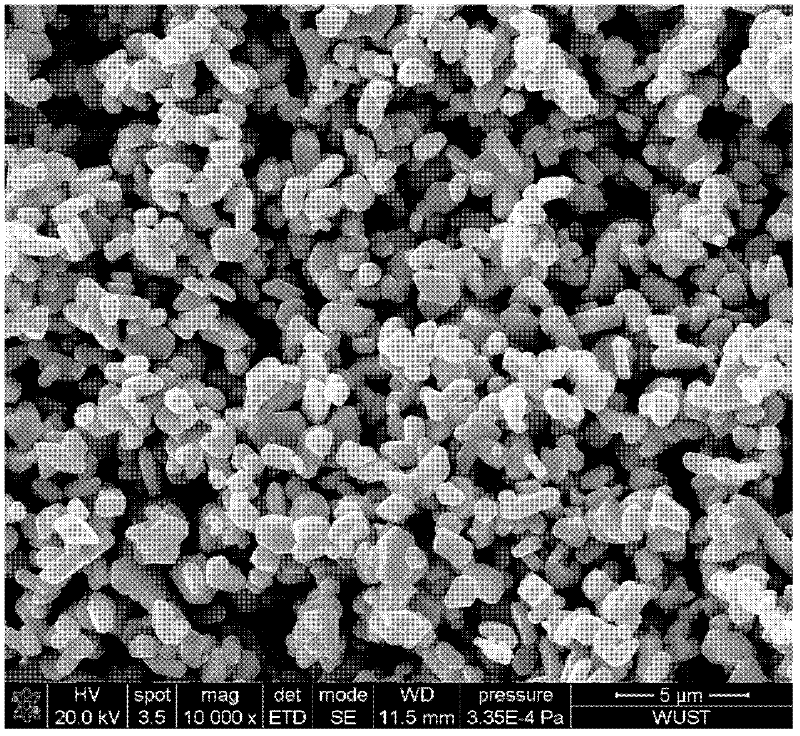

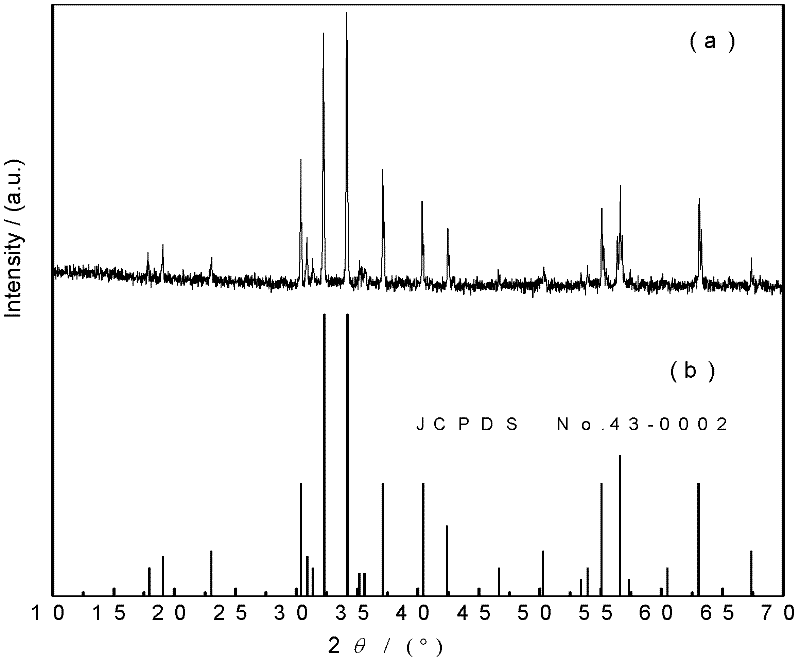

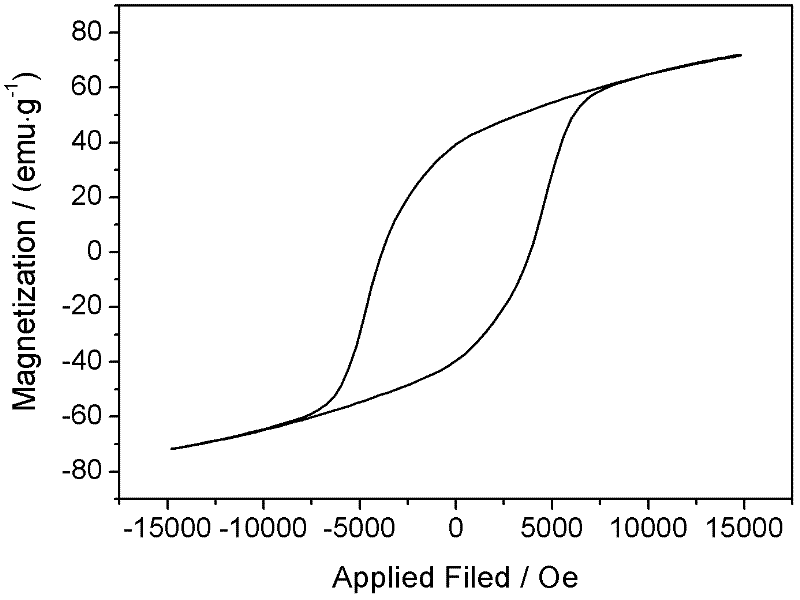

A technology of barium ferrite and reaction medium is applied in the field of preparation of barium ferrite materials, which can solve the problems of inability to meet the purity of high-performance barium ferrite, particle size distribution of particle agglomeration, narrow particle size distribution, etc. Good regular hexagonal flake micromorphology, narrow particle size distribution, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for synthesizing high-performance barium ferrite with molten salt as a flux and a reaction medium, comprising the following steps:

[0025] 1) Fe 2 o 3 with BaCO 3 Press Fe 3+ / Ba 2+ molar ratio n(Fe 3+ ) / n(Ba 2+ )=12 Weigh the corresponding amount of Fe respectively 2 o 3 , BaCO 3 Mix to get reactants;

[0026] 2) Weigh and mix NaCl and KCl according to the molar ratio of NaCl and KCl being 1:1 to obtain a mixed salt (or molten salt, which is the reaction solvent and molten salt medium);

[0027] 3) According to R=total mass of mixed salt / total mass of reactant=1, mix reactant and mixed salt, put into agate jar, add absolute ethanol (use absolute ethanol as the ball milling medium, the mass ratio of ball to material is 3 : 1), ball milled and mixed on a planetary ball mill (ball milled for 180 minutes), then dried (i.e. dried), then put into a corundum crucible with a cover and kept at 1000° C. for 3 hours in an electric furnace,

[0028] 4) After t...

Embodiment 2

[0030] A method for synthesizing high-performance barium ferrite with molten salt as a flux and a reaction medium, comprising the following steps:

[0031] 1) The reactant Fe 2 o 3 with BaCO 3 Press Fe 3+ / Ba 2+ molar ratio n(Fe 3+ ) / n(Ba 2+)=11.5 Weigh the corresponding amount of Fe respectively 2 o 3 , BaCO 3 Mix to get reactants;

[0032] 2) Weigh and mix NaCl and KCl according to the molar ratio of NaCl and KCl being 1:1 to obtain a mixed salt (or molten salt, which is the reaction solvent and molten salt medium);

[0033] 3) According to R=total mass of mixed salt / total mass of reactant=1, mix reactant and mixed salt, put into agate jar, add absolute ethanol (use absolute ethanol as the ball milling medium, the mass ratio of ball to material is 3 : 1), on a planetary ball mill, ball milled and mixed (ball milled for 180 minutes), then dried, then put into a corundum crucible with a cover and insulated at 1000°C for 3h in an electric furnace,

[0034] 4) After t...

Embodiment 3

[0039] A method for synthesizing high-performance barium ferrite with molten salt as a flux and a reaction medium, comprising the following steps:

[0040] 1) The reactant Fe 2 o 3 with BaCO 3 Press Fe 3+ / Ba 2+ molar ratio n(Fe 3+ ) / n(Ba 2+ )=11 Weigh the corresponding amount of Fe respectively 2 o 3 , BaCO 3 Mix to get reactants;

[0041] 2) Weighing NaCl and KCl according to the molar ratio of NaCl and KCl being 1:1 and mixing to obtain a mixed salt;

[0042] 3) According to R=total mass of mixed salt / total mass of reactant=1, mix reactant and mixed salt, put into agate jar, add absolute ethanol (use absolute ethanol as the ball milling medium, the mass ratio of ball to material is 3 : 1), on a planetary ball mill, ball milled and mixed (ball milled for 180 minutes), then dried, then put into a corundum crucible with a cover and insulated at 1000°C for 3h in an electric furnace,

[0043] 4) After the furnace temperature is naturally cooled to room temperature, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com