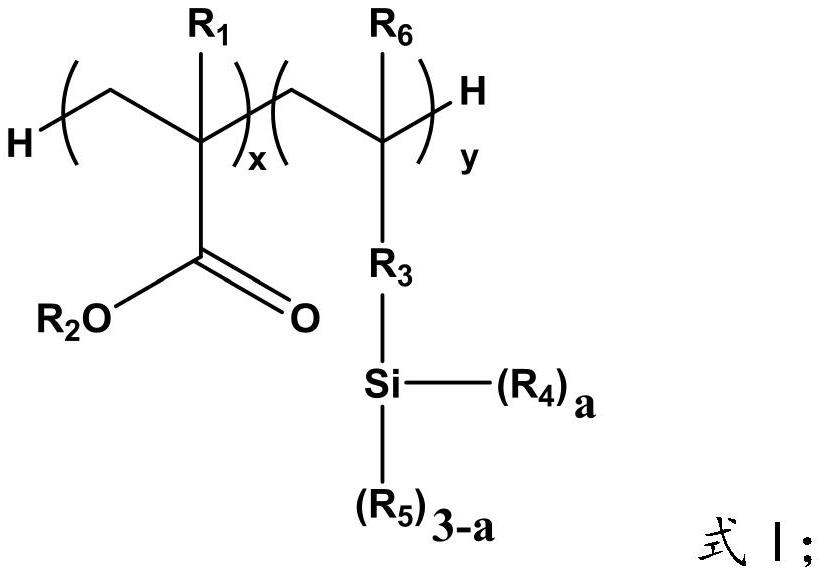

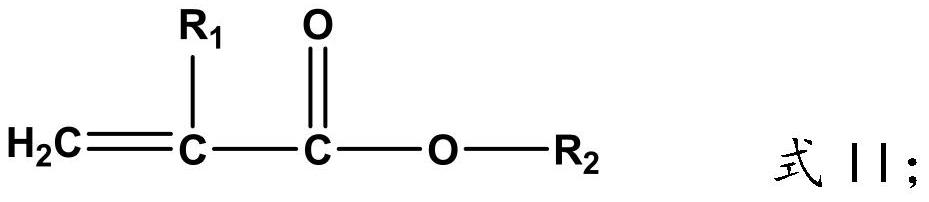

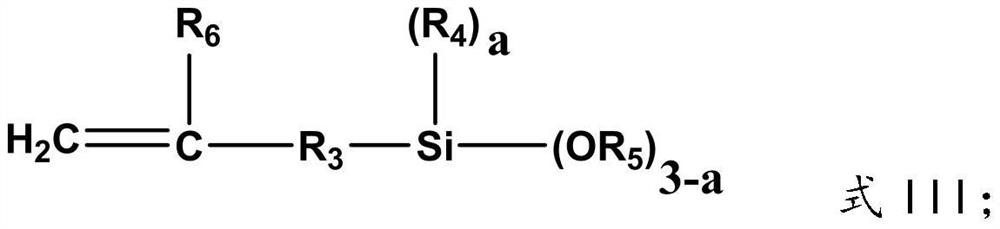

Silane polymer for negative electrode bonding of lithium ion battery and preparation method thereof

A lithium-ion battery, silane polymer technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of inability to meet the requirements of mechanical flexibility of lithium battery binders, low reversible cycle capacity, etc., and achieve improved electrochemical performance. performance, good polarity effect, short duration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First, add 25 g (0.305 mol) acrylic acid, 0.032 g initiator azobisisobutyronitrile, and 32 mL butyl acetate solvent into a four-necked round-bottomed flask, and continue to add 6.5 g (0.039 mol) vinyltrimethoxycarbonate under stirring. Silane was added dropwise to the four-necked flask; then the temperature was raised to 65°C, and the reaction was kept stirring for 12 h; the reaction solution obtained from the reaction was transferred to a rotary evaporator, and the excess solvent was evaporated to obtain a viscous solid; finally, the viscous solid was placed in a Vacuum-drying at 100° C. for 8 hours to obtain the silane polymer for bonding the negative electrode of the lithium ion battery.

[0042] The molar ratio of the ester compound to the silane compound is 0.75-10:1; the dosage of the initiator is 0.1%-0.9% of the weight sum of the ester compound and the silane compound;

Embodiment 2

[0044] First, add 25 g (0.291 mol) methyl acrylate, 0.12 g initiator ammonium persulfate, and 40 mL ethyl propionate solvent into a four-necked round-bottomed flask, and continue to add 15 g (0.037 mol) vinyl trilactic acid under stirring Ethyl ester silane was added dropwise to the four-necked flask; then the temperature was raised to 85°C, and the reaction was kept stirring for 6 hours; the reaction solution obtained from the reaction was transferred to a rotary evaporator, and the excess solvent was evaporated to obtain a viscous solid; finally, the viscous solid was Vacuum drying was carried out at 100° C. for 8 hours to obtain the silane polymer for bonding the negative electrode of the lithium ion battery.

Embodiment 3

[0046] First, add 25 g (0.250 mol) of ethyl acrylate, 0.13 g of initiator azobisisobutyronitrile, and 44 mL of butyl acetate solvent into a four-necked round-bottomed flask, and continue to add 19 g (0.037 mol) of propenyl under stirring. Ethyl trilactate silane was added dropwise to the four-necked flask; then the temperature was raised to 70 °C, and the temperature was kept stirring for 10 h; the reaction solution obtained from the reaction was transferred to a rotary evaporator, and the excess solvent was evaporated to obtain a viscous solid; finally, the viscous solid was The thick solid was vacuum-dried at 80° C. for 10 hours to obtain the silane polymer for the negative electrode binding of the lithium ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com