Phase change temperature control fiber, yarn and fabric and application thereof

A fiber and phase change technology, applied in fiber processing, fiber type, fiber chemical characteristics, etc., can solve the problems of poor cycle stability, easy leakage of phase change materials, and poor cycle stability of phase change composite fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

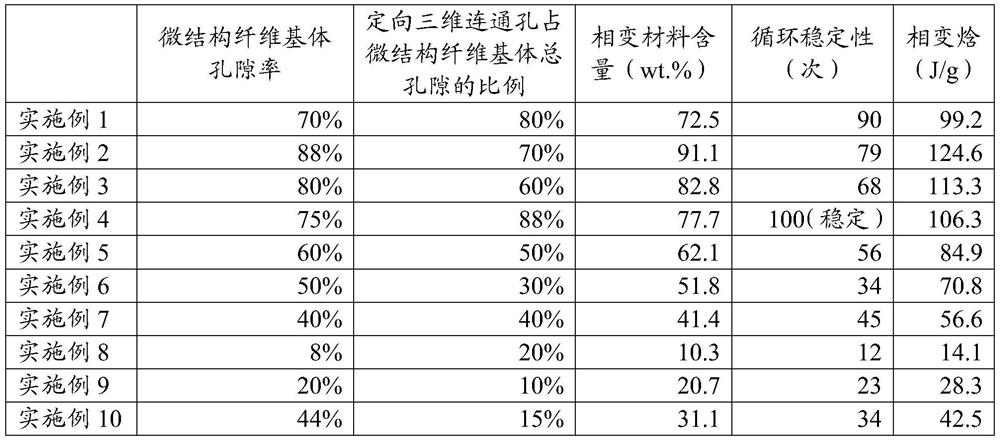

Embodiment 1

[0063] (1) Mix polyethylene (PE) particles and polyethylene oxide (PEO) particles according to the mass ratio = 5.25:4.75, and extrude the mixed material through a twin-screw extruder at 260 ° C and 4 MPa pressure. , to obtain composite material masterbatch after solidification and slicing. After the composite material masterbatch is dried, it is filled into the feed port of the melt spinning machine, and the temperature of each zone of the melt spinning machine is adjusted to 180°C, 230°C, 230°C and 230°C respectively. Under the conditions of screw speed of 20 Hz and stable screw pressure of 5.6 MPa, fibers were prepared by melt composite spinning, and composite fibers were obtained by doffing at a winding speed of 300 m / min.

[0064] (2) Stretch the composite fiber obtained above at room temperature (stretch ratio is 4), and heat and soak in solvent water at 60° C. for more than 4 hours to remove PEO to obtain microstructured fibers.

[0065] (3) Melt the phase change mater...

Embodiment 2

[0069] The difference between embodiment 2 and embodiment 1 is that polyethylene (PE) particles and polyethylene oxide (PEO) particles are mixed according to mass ratio=4.75:5.25 in step (1); Down stretch (stretch ratio 3.6). Other reaction conditions are with embodiment 1.

[0070] The measured porosity of the microstructured fiber matrix is 88%, and the ratio of the oriented three-dimensional interconnected pores to the total pores of the microstructured fiber matrix is 70%.

Embodiment 3

[0072] The difference between embodiment 3 and embodiment 1 is that polyethylene (PE) particles and polyethylene oxide (PEO) particles are mixed according to mass ratio=4.9:5.1 in step (1); Down stretch (stretch ratio is 3). Other reaction conditions are with embodiment 1.

[0073] The measured porosity of the microstructured fiber matrix is 80%, and the ratio of the oriented three-dimensional interconnected pores to the total pores of the microstructured fiber matrix is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com