High-entropy alloy resistant to high-temperature oxidation, thermal barrier coating and preparation method thereof

A high-temperature oxidation-resistant, high-entropy alloy technology, applied in metal material coating technology, coating, fusion spraying, etc., can solve the problems of unreachable high-entropy alloys and unspecified application occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

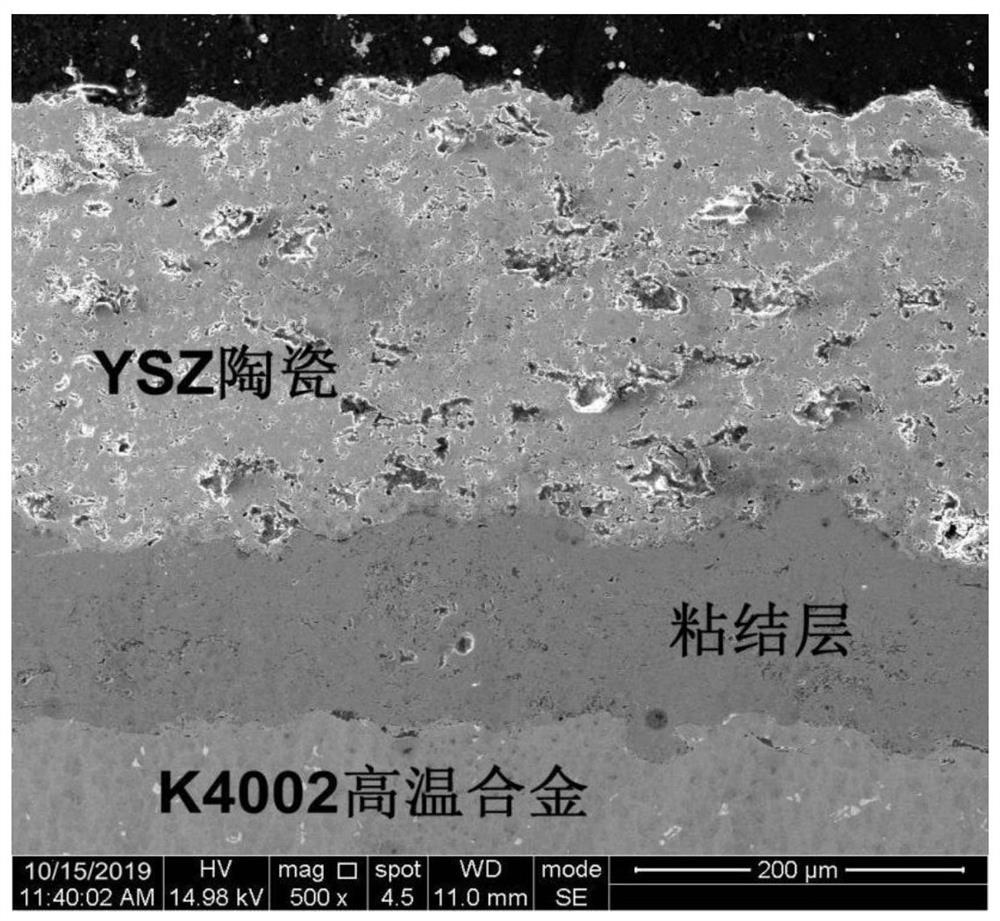

[0034] In this embodiment, the preparation method of the barrier coating comprises the following steps:

[0035] Step 1: According to the composition of the bonding layer alloy, calculate the demand for pure metal and intermediate alloy raw materials, and prepare materials;

[0036]Step 2: Put the material in a vacuum electric arc furnace for melting to obtain an AlCoCrFeNiTaHfY high-entropy alloy ingot; the molar content of each element in the AlCoCrFeNiTaHfY high-entropy alloy is: Al 16-22%, Co 14-20%, Cr 14-20%, Fe 5-8%, Ni 38-45%, Ta 1-2%, Hf 0.02-0.1%, and Y 0.2-0.5%.

[0037] The electric arc furnace adopts non-consumable vacuum tungsten arc furnace, equipped with water-cooled copper crucible, and the electric arc furnace is vacuumed to 5×10 before melting -3 Below Pa, feed Ar gas to keep the air pressure in the electric arc furnace at 0.4-0.6 MPa to prevent excessive volatilization of metals under the arc.

[0038] The electrode voltage is 30-50V, and the current is 5...

Embodiment 1

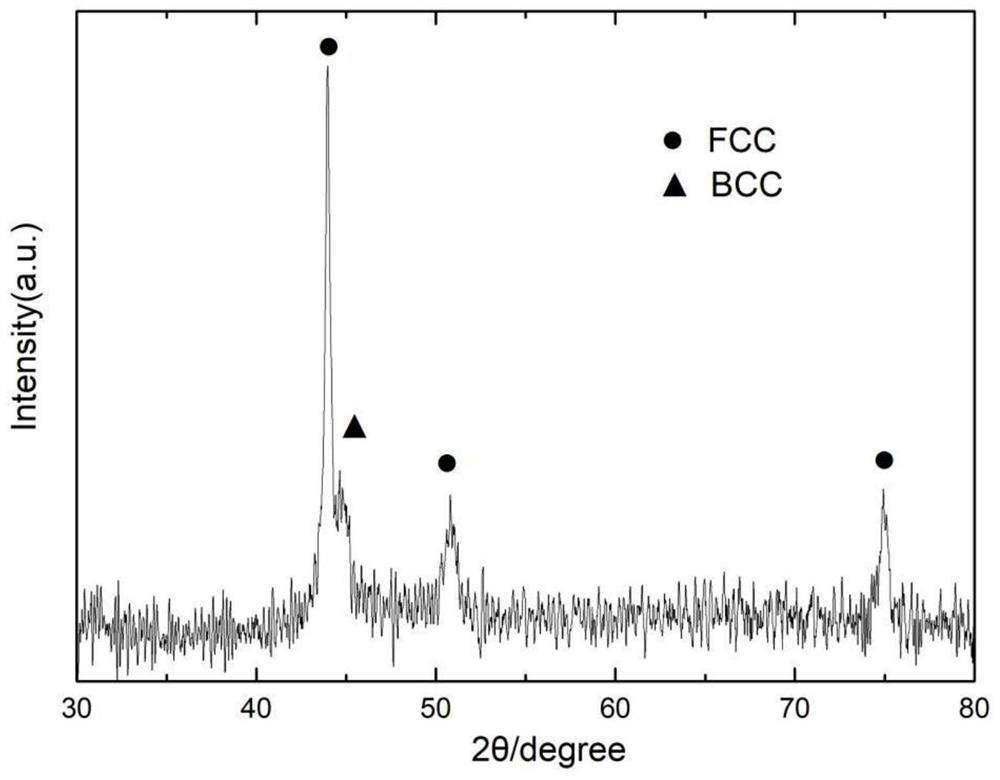

[0053] Calculate the alloy composition 18.00Al-16.12Co-16.12Cr-6.16Fe-42.25Ni-1Ta-0.05Hf-0.3Y (mole percent) to obtain the weighted melting point T of the alloy m , mixing entropy ΔS mix , Mixing enthalpy ΔH mix , atomic size difference δ, parameter Ω, and valence electron concentration VEC are listed in Table 1. NiCoCrAlY (composition 40.95Ni-19.74Co-16.54Cr-22.49Al-0.28Y, mole percent) is listed as a comparison. 18.00Al-16.12Co-16.12Cr-6.16Fe-42.25Ni-1Ta-0.05Hf-0.3Y alloy satisfies ΔS mix ≥1.5R (R is the ideal gas constant), parameter Ω>1.1, ΔH mix It is between (-15~3.2) kJ / mol, so it can be called a high-entropy alloy.

[0054] Table 1 Calculation of relevant parameters of high-entropy alloys

[0055]

Embodiment 2

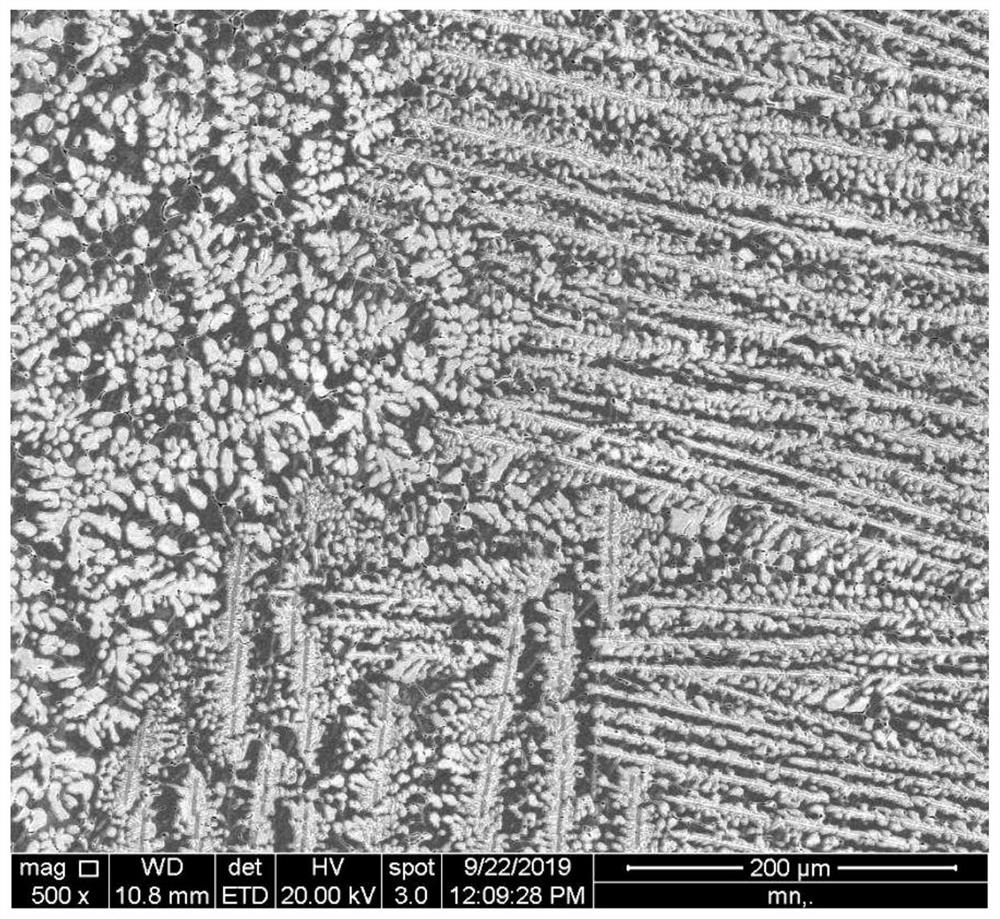

[0057] Preparation of alloy ingots, alloy powders and thermal barrier coatings. Put the raw materials Al, Co, Cr, Fe, Ni, Hf, Ta (all with a purity of 99.9wt% and above) and Al-Y master alloy in 95% absolute ethanol for 10 minutes of ultrasonic cleaning to remove the oily impurities on the surface Afterwards, dry in a drying oven at 50°C. The high-entropy alloy is composed of 18.00Al-16.12Co-16.12Cr-6.16Fe-42.25Ni-1Ta-0.05Hf-0.3Y (mole percent), and the raw materials are weighed and batched with an electronic balance with an accuracy of 0.001g. A non-consumable vacuum electric arc furnace was used for smelting, and a total of 6 alloy ingots of about 50 g were smelted. Put the proportioned materials in the water-cooled copper crucible according to the melting point from low to high and from bottom to top. First use the mechanical pump to evacuate to 5Pa, and then use the molecular pump to continue to evacuate to 5×10 -3 Pa below, then filled with high-purity argon so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com