Method for high-pressure solid-phase synthesis of iodine-copper-cesium lead-free quantum dot

A cesium lead-free quantum, solid-phase synthesis technology, applied in the field of nanomaterials, can solve problems such as inability to obtain samples and complex preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

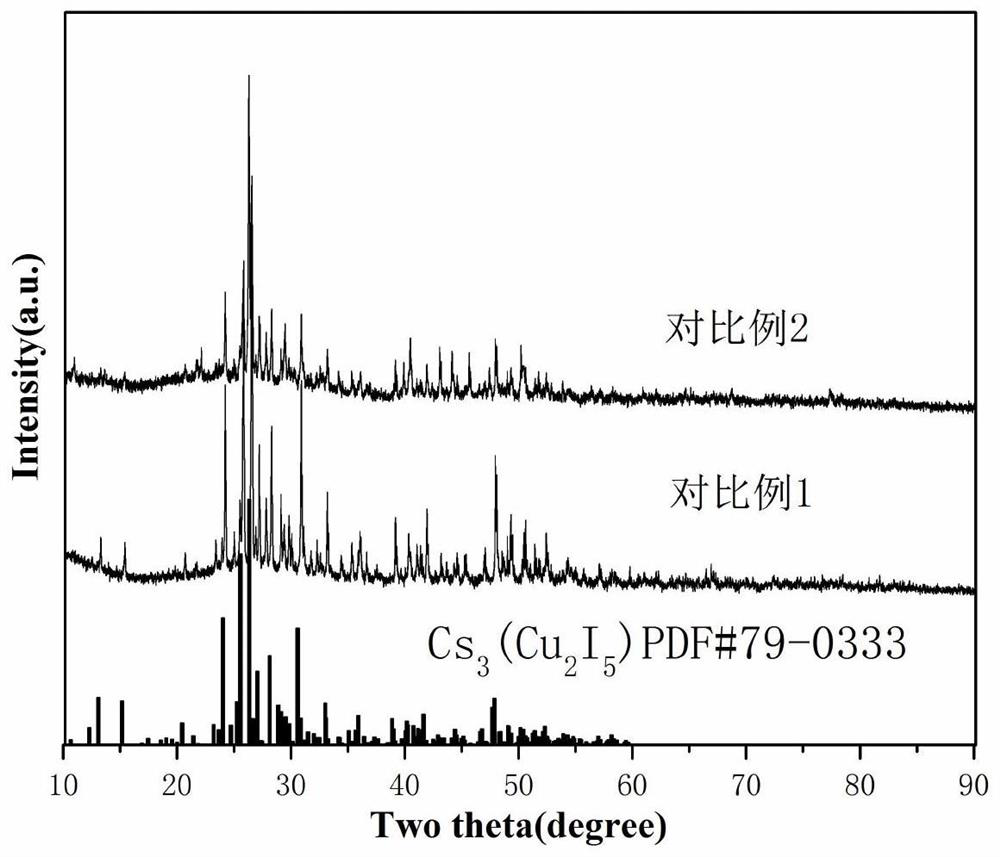

Embodiment 1

[0027] CsI 60mol%;

[0028] CuI 40mol%;

[0029] The sample was prepared by a high-pressure solid-phase reaction method, which specifically included the following steps:

[0030] (1) Take by weighing each required composition raw material respectively by molar ratio;

[0031] (2) Grind and mix each constituent raw material in an agate mortar respectively, put it into a tablet press mold, and hold the pressure at 20 MPa for 10 minutes to make the powder mixture completely tablet-shaped;

[0032] (3) Put the prepared sample into the graphite tube, put the graphite block and the boron nitride block into the tube so that the planes of both ends are parallel, then put the boron nitride tube outside the graphite tube, and place the two ends Put the molybdenum sheet on, and put the electrodes at the same time, so that the planes of the two ends are parallel, and then put it into the mold required by the six-sided top press, so that the two sides of the mold with electrodes are ke...

Embodiment 2

[0035] CsI 60mol%;

[0036] CuI 40mol%;

[0037] The sample was prepared by a high-pressure solid-phase reaction method, which specifically included the following steps:

[0038] (1) Take by weighing each required composition raw material respectively by molar ratio;

[0039] (2) Grind and mix each constituent raw material in an agate mortar respectively, put it into a tablet press mold, and hold the pressure at 20 MPa for 10 minutes to make the powder mixture completely tablet-shaped;

[0040] (3) Put the prepared sample into the graphite tube, put the graphite block and the boron nitride block into the tube so that the planes of both ends are parallel, then put the boron nitride tube outside the graphite tube, and place the two ends Put the molybdenum sheet on, and put the electrodes at the same time, so that the planes of the two ends are parallel, and then put it into the mold required by the six-sided top press, so that the two sides of the mold with electrodes are ke...

Embodiment 3

[0043] CsI 60mol%;

[0044] CuI 40mol%;

[0045] The sample was prepared by a high-pressure solid-phase reaction method, which specifically included the following steps:

[0046] (1) Take by weighing each required composition raw material respectively by molar ratio;

[0047] (2) Grind and mix each constituent raw material in an agate mortar respectively, put it into a tablet press mold, and hold the pressure at 20 MPa for 10 minutes to make the powder mixture completely tablet-shaped;

[0048] (3) Put the prepared sample into the graphite tube, put the graphite block and the boron nitride block into the tube so that the planes of both ends are parallel, then put the boron nitride tube outside the graphite tube, and place the two ends Put the molybdenum sheet on, and put the electrodes at the same time, so that the planes of the two ends are parallel, and then put it into the mold required by the six-sided top press, so that the two sides of the mold with electrodes are ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com