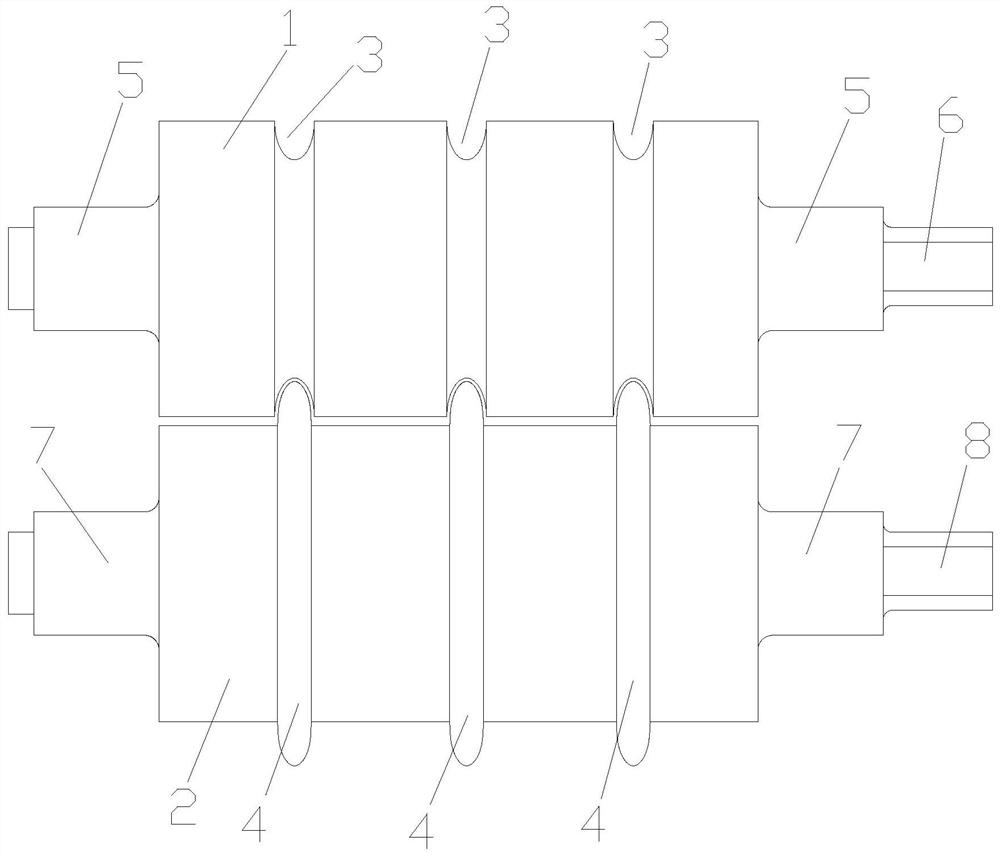

Improved type aluminum alloy profile steel finished product roller and manufacturing method thereof

A manufacturing method and chrome alloy technology, applied in metal rolling, metal rolling, rolls, etc., can solve the problem of less quality rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]A manufacturing method of an improved chromium alloy section steel finished roll, comprising the following production steps: S1, configuration chemical composition: C: 0.45%; Si: 0.45%; Mn: 0.45%; P: 0.010%; S: 0.0:10% ; Cr: 5.50%; Ni: 0.50%; V: 0.50%; Nb: 0.15%; Re: 0.05%; Stir with an electromagnetic mixer for 3 minutes; refine after removing slag; heat up to 1550°C for secondary slagging; add 3 kg / ton of steel yttrium-based heavy rare earth molten steel modifier after slagging to remove impurity elements; Alloy 0.03% ton steel, tap after 3 minutes; blow argon gas into the ladle to let the micro-slag float up, stop blowing for 3 minutes, calm the molten steel for 6 minutes, and pour the steel temperature to the liquidus temperature +30°C; pouring in S2 adopts the top pouring process , after pouring, start the electromagnetic vibrator with a frequency of 60 times, so that the molten steel can increase the density during the sequential solidification process, refine the ...

Embodiment 2

[0026] A method for manufacturing an improved chromium alloy steel finished roll, comprising the following production steps: S1, configuration chemical composition: C: 0.60%; Si: 0.60%; Mn: 0.65%; P: 0.020%; S: 0.020%; Cr : 5.80%; Ni: 0.70%; V: 0.65%; Nb: 0.25%; Stir with an electromagnetic mixer for 4 minutes; refine after removing slag; heat up to 1560°C and then make a second slag; Aluminum alloyed with 0.04% ton steel, tapped after 5 minutes; argon gas was blown into the ladle to let the micro-slag float up, the blowing was stopped for 5 minutes, the molten steel was calmed for 8 minutes, and the steel temperature reached the liquidus temperature of 40°C for pouring; the pouring in S2 adopts the top pouring process, After pouring, start the electromagnetic vibrator with a frequency of 80 times to increase the density of the molten steel during the sequential solidification process, refine the crystal microstructure, and eliminate the loose area; S3, special heat treatment:...

Embodiment 3

[0028] A method for manufacturing an improved chromium alloy steel finished roll, comprising the following production steps: S1, configuration chemical composition: C: 0.75%; Si: 0.80%; Mn: 0.80%; P: 0.020%; S: 0.020%; Cr : 6.30%; Ni: 0.67%; V: 0.70%; Nb: 0.25%; Re: 0.0: 8%; S2, smelting and pouring: smelting pure molten steel, adding alloy when the steel temperature reaches 1500°C; Stir with an electromagnetic mixer for 5 minutes; refine after removing slag; heat up to 1570°C and then make a second slag; Aluminum alloyed with 0.05% ton steel, tapped after 10 minutes; argon gas was blown into the ladle to let the micro-slag float up, the blowing was stopped for 10 minutes, the molten steel was calmed for 10 minutes, and the steel temperature reached the liquidus temperature of 50°C for pouring; the pouring in S2 adopts the top pouring process, After pouring, start the electromagnetic vibrator with a frequency of 120 times to increase the density of the molten steel during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com