Low-mismatch novel high-strength steel and preparation method thereof

A high-strength steel, a new type of technology, applied in the field of preparation of high-strength steel, can solve the problems of difficult to further exert mechanical properties and high interphase lattice mismatch, and achieve the effect of improving strong plasticity, reducing interphase mismatch, and ensuring toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A novel high-strength steel with a low mismatch degree and a preparation method thereof, comprising the following steps;

[0021] 1), weigh the alloy composition, weigh 0.2wt.% of C, 3.0wt.% of Si, 5.0wt.% of Mn, 0.5wt.% of Ni according to the weight percentage of the alloy composition, and the balance is Fe;

[0022] 2), smelting, casting and forging, vacuum smelting and casting the alloy components weighed in step 1), and then forging at a temperature of 1050° C., with a forging ratio of 3.0, to obtain a forged billet with a thickness of 60 mm;

[0023] 3) Hot rolling, the 60mm thick forging billet is kept at 1200°C for 2.5h, and then hot rolled at 1100°C to 2.4mm, with a total reduction rate of 95%;

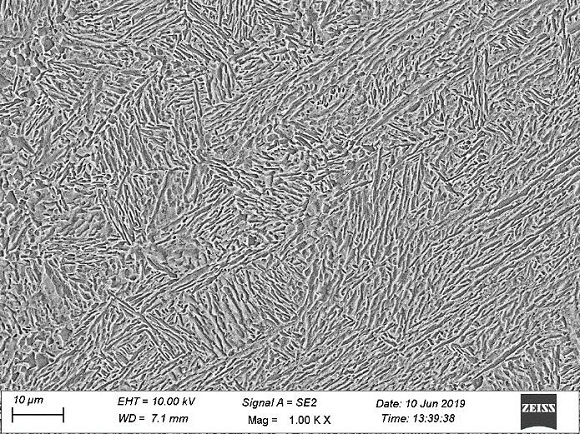

[0024] 4) heat treatment, heat the obtained hot-rolled plate at 1000°C for 15 minutes, then water quench to room temperature, then hold at 760°C for 0.5h, and air-cool to room temperature to obtain the low-mismatch degree novel high-strength steel of the present inventi...

Embodiment 2

[0028] A novel high-strength steel with a low mismatch degree and a preparation method thereof, comprising the following steps;

[0029] 1), weigh the alloy composition, weigh 0.1wt.% of C, 4.5wt.% of Si, 10.0wt.% of Mn, 0.9wt.% of Ni according to the weight percentage of the alloy composition, and the balance is Fe;

[0030] 2), smelting, casting and forging, vacuum smelting and casting the alloy components weighed in step 1), and then forging at a temperature of 1150° C., with a forging ratio of 1.5, to obtain a forged billet with a thickness of 70 mm;

[0031] 3) Hot rolling, the 70mm thick forging billet is kept at 1250°C for 2h, and then hot rolled at 1150°C, the hot rolling reaches 3mm, and the total reduction rate is 95%;

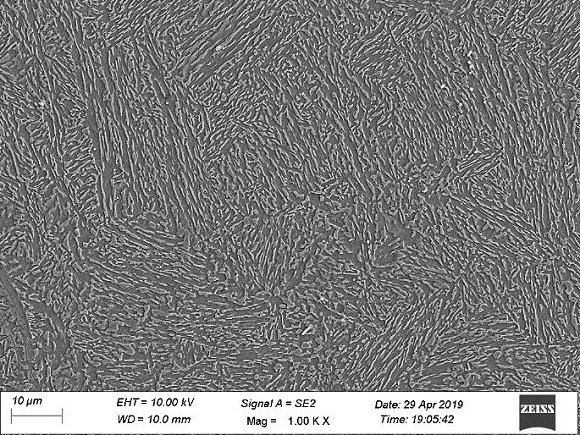

[0032] 4) heat treatment, heat the obtained hot-rolled plate at 950°C for 30 minutes, water quench it at room temperature, then hold it at 740°C for 1 hour, and air-cool to room temperature to obtain the low-mismatch high-strength steel of the presen...

Embodiment 3

[0036] A novel high-strength steel with a low mismatch degree and a preparation method thereof, comprising the following steps;

[0037] 1), weigh the alloy composition, weigh 0.4wt.% of C, 5.0wt.% of Si, 7.5wt.% of Mn, 1.5wt.% of Ni according to the weight percentage of the alloy composition, and the balance is Fe;

[0038] 2), smelting, casting and forging, vacuum smelting and casting the alloy components weighed in step 1), and then forging at a temperature of 1130° C., with a forging ratio of 2.2, to obtain a forged billet with a thickness of 100 mm;

[0039] 3) Hot rolling, the 100mm thick forging billet is kept at 1220°C for 2.2h, and then hot rolled at 1120°C to 4mm, with a total reduction rate of 95%;

[0040] 4) heat treatment, heat the obtained hot-rolled plate at 1050°C for 15 minutes, then water quench to room temperature, then hold at 840°C for 0.6h, and air-cool to room temperature to obtain the low-mismatch degree novel high-strength steel of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com