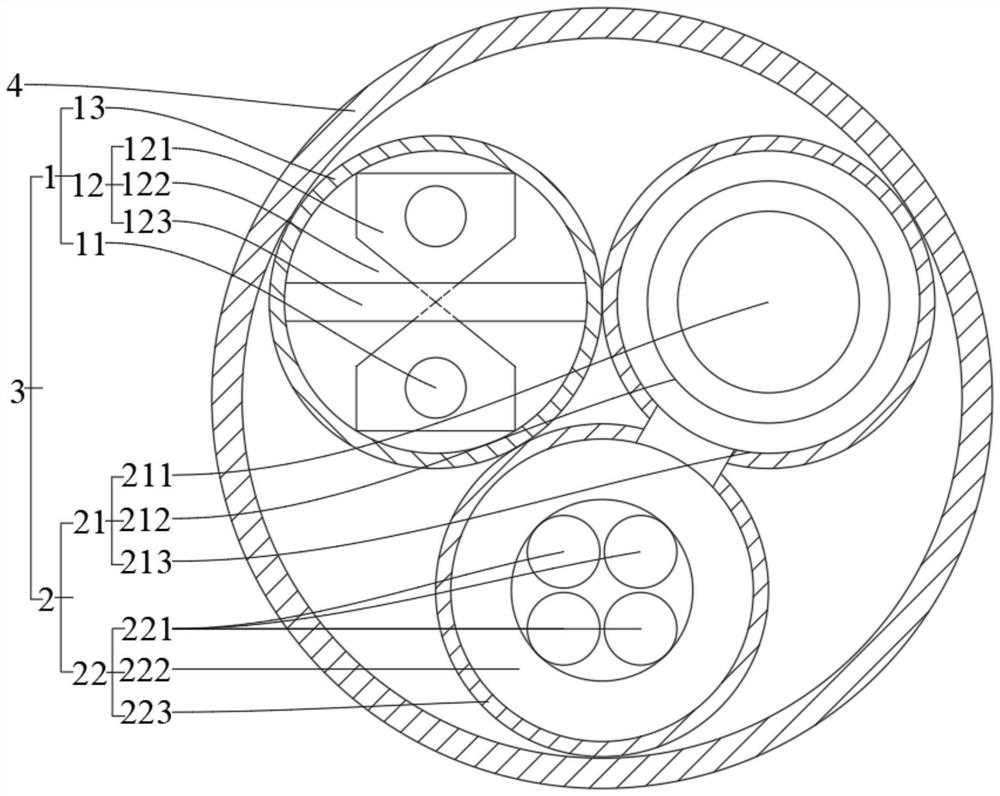

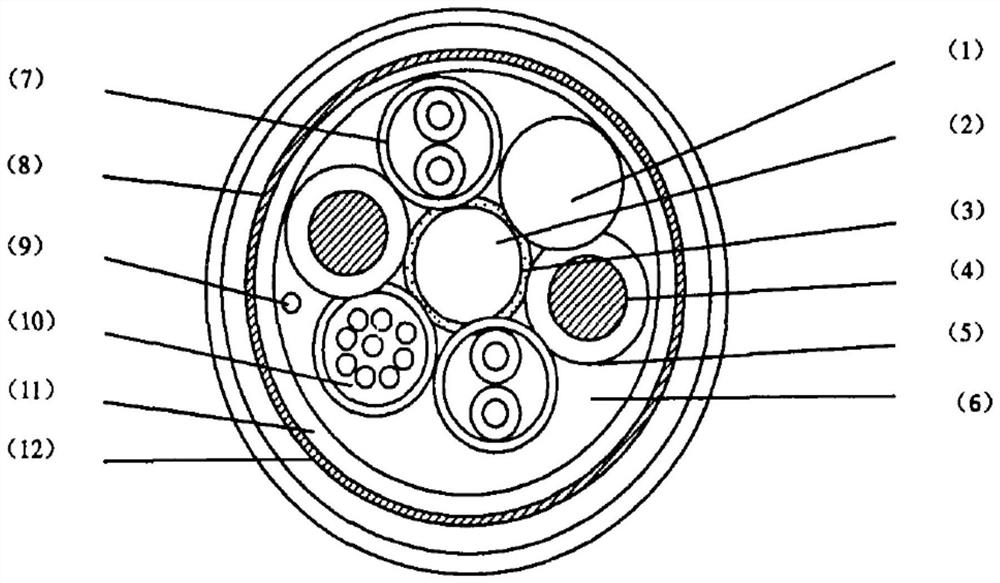

A kind of flame-retardant optoelectronic hybrid cable of coaxial electric unit and its manufacturing method

A technology of photoelectric hybrid cable and coaxial electrical unit, which is applied in the direction of cable/conductor manufacturing, communication cable, insulated cable, etc. It can solve problems such as equipment corrosion, cable skin wear, and network density increase, so as to enhance mechanical strength and reduce Effects of signal interference and enhancement of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

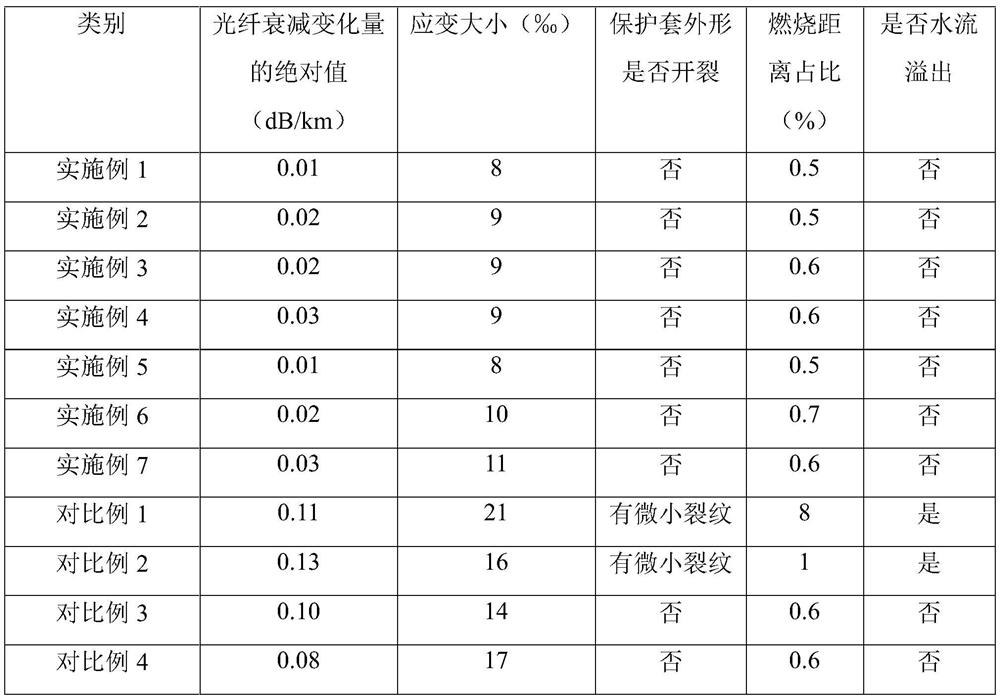

Embodiment 2

[0047] Change the raw materials of the non-hygroscopic protective layer 222 to 20 parts of silicone-modified polyacrylate emulsion, 40 parts of soft polyurethane, and 15 parts of polyethylene oxide; at the same time, the raw material of the protective cover is 20 parts of ethylene - Acetate copolymer, 30 parts of melamine formaldehyde resin, 5 parts of silicone masterbatch, 10 parts of triphenyl phosphite and 10 parts of almond oil; the rest of the formula, steps and device design are the same as in Example 1.

Embodiment 3

[0049] Change the raw materials of the non-hygroscopic protective layer 222 to 20 parts of silicone-modified polyacrylate emulsion, 40 parts of soft polyurethane, and 15 parts of polyethylene oxide; at the same time, the raw material of the protective cover is 30 parts of ethylene - Acetate copolymer, 40 parts of melamine formaldehyde resin, 10 parts of silicone masterbatch, 15 parts of triphenyl phosphite and 20 parts of almond oil; the rest of the formula, steps and device design are the same as in Example 1.

Embodiment 4

[0051] Change the raw materials of the non-hygroscopic protective layer 222 to 30 parts of silicone-modified polyacrylate emulsion, 50 parts of soft polyurethane, and 30 parts of polyethylene oxide; at the same time, the raw material of the protective cover is 20 parts of ethylene - Acetate copolymer, 30 parts of melamine formaldehyde resin, 5 parts of silicone masterbatch, 10 parts of triphenyl phosphite and 10 parts of almond oil; the rest of the formula, steps and device design are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com