Catalyst for liquid phase hydrogenation, and preparation method and application thereof

A liquid-phase hydrogenation and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and preparation of hydroxyl compounds. Solve problems such as poor dispersion of active components, and achieve the effects of good catalyst uniformity, improved combination mode, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

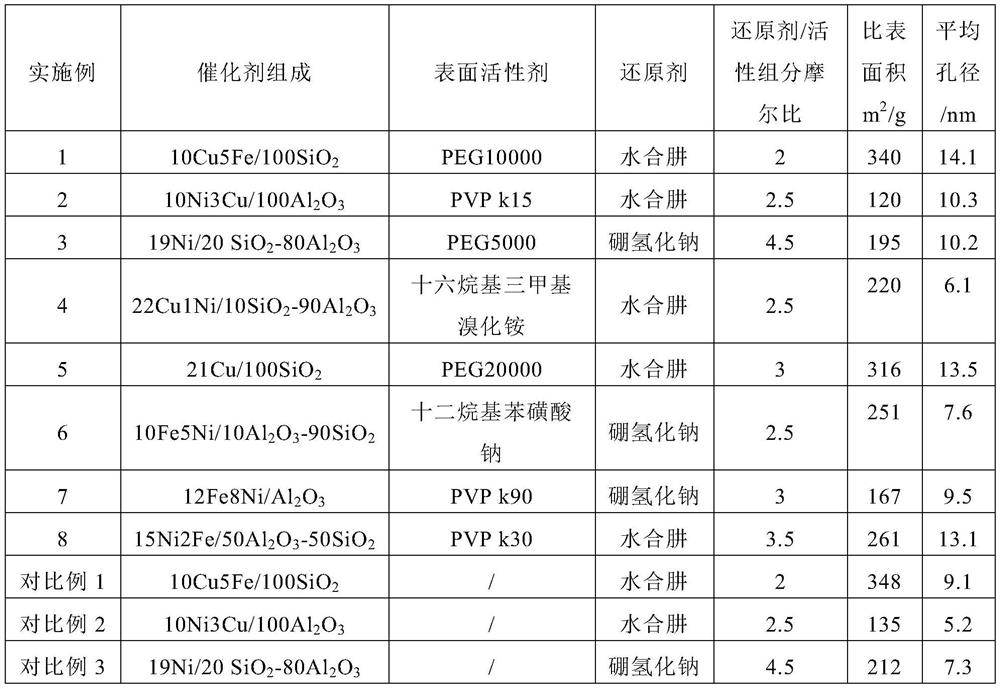

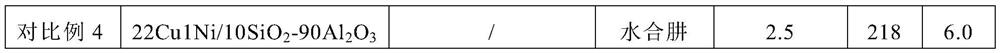

[0038] The concrete steps of preparation method are as follows:

[0039] (1) Weigh a certain amount of silica sol and / or aluminum sol respectively, add water to dilute to SiO 2 and or Al 2 o 3 The mass concentration is 5-20%;

[0040] (2) Weigh a certain amount of copper / iron / nickel nitrate or acetate, add water to dissolve, and prepare a solution with a concentration of 0.5-2mol / L.

[0041] (3) Weigh a certain amount of surfactant, one or more of polyethylene glycol, polyvinylpyrrolidone, sodium dodecylbenzenesulfonate or cetyltrimethylammonium bromide can be used to add water Dissolve and configure to obtain a solution with a concentration of 5-30g / L. The mass ratio of the added surfactant to the carrier is 1-5:100. Among the above-mentioned surfactants, polyethylene glycol and polyvinylpyrrolidone are mainly used for pore expansion ; Sodium dodecylbenzenesulfonate or cetyltrimethylammonium bromide are used to adjust the binding mode between the active ingredient and the...

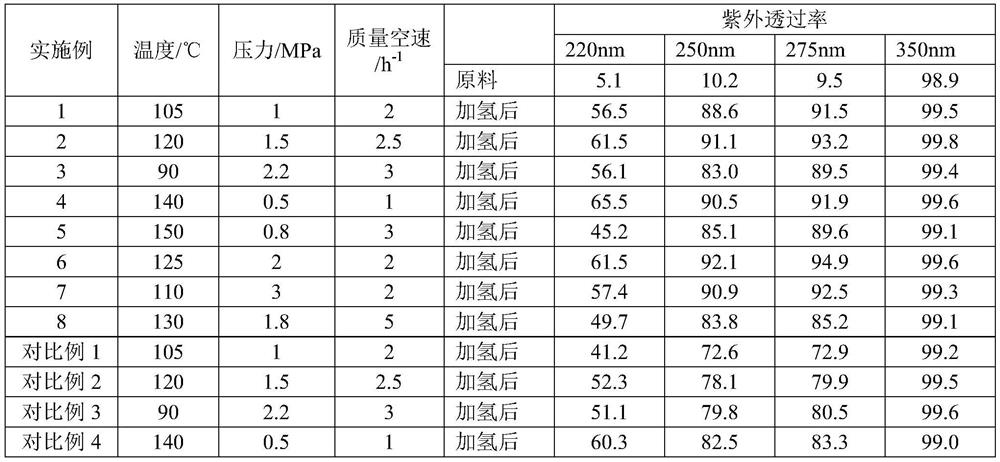

Embodiment 1

[0048] Weigh 200g of silica sol with a content of 25%, add water and dilute to 400ml to obtain sol 1; then weigh 9.5g copper nitrate trihydrate and 9.02g copper nitrate nonahydrate, add water to dissolve in 200ml to obtain solution 2; weigh 1g PEG10000, Add water to 100ml and stir to dissolve to obtain solution 3; add solutions 2 and 3 to solution 1 respectively, stir while adding, then adjust the pH to 2.0 with nitric acid, then slowly raise the temperature to 80°C, continue stirring for 1 hour, stop stirring, and Aged for 4 hours, dried in an oven at 120°C after taking it out, and calcined in a muffle furnace at 400°C for 4 hours to obtain a catalyst. The catalyst composition is shown in Example 1 in Table 1.

Embodiment 2

[0051] Weigh 200g of aluminum sol with a content of 25%, add water to dilute to 400ml, and obtain Sol 1; then weigh 2.35g of copper acetate monohydrate and 7.53g of nickel acetate, add water to dissolve in 200ml, and obtain solution 2; weigh 1.5g of PVP k15, Add water to 100ml and stir to dissolve to obtain solution 3; add solutions 2 and 3 to solution 1 respectively, stir while adding, then adjust the pH to 3.5 with nitric acid, then slowly raise the temperature to 70°C, continue stirring for 1 hour, then stop stirring, and Aged for 4 hours, dried in an oven at 120°C after taking it out, and calcined in a muffle furnace at 450°C for 4 hours to obtain a catalyst. Catalyst composition see Example 2 in Table 1.

[0052] Catalyst evaluation uses a fixed bed hydrogenation reactor, the catalyst is loaded with 10.0g, the upper and lower sides of the catalyst bed are filled with quartz sand, and the catalyst is reduced with hydrazine hydrate before use. The hydrazine hydrate is pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com