Submarine X70-grade pipeline steel resistant to hydrogen sulfide corrosion and production method thereof

A technology for anti-hydrogen sulfide and pipeline steel, applied in the field of pipeline steel, can solve the problems of unfavorable mechanical properties and anti-hydrogen sulfide corrosion performance, insufficient anti-hydrogen sulfide corrosion performance, and inability to meet the requirements of submarine acid-resistant pipelines, so as to improve the anti-HIC performance , Improve the anti-SSCC performance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

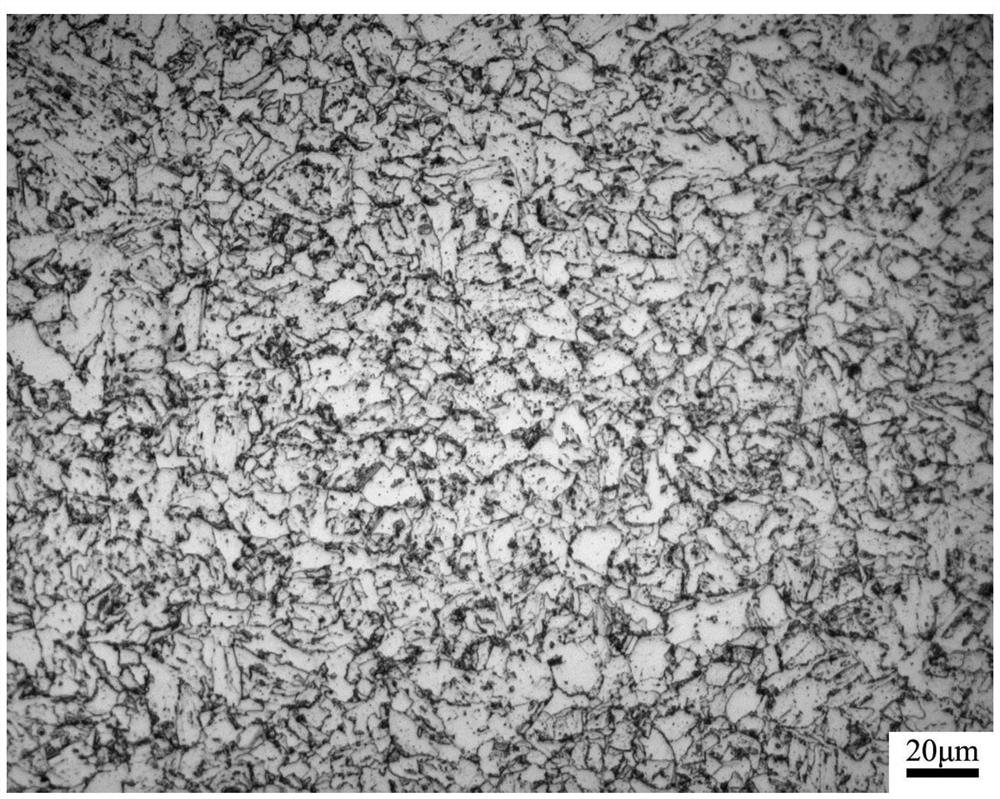

Image

Examples

Embodiment Construction

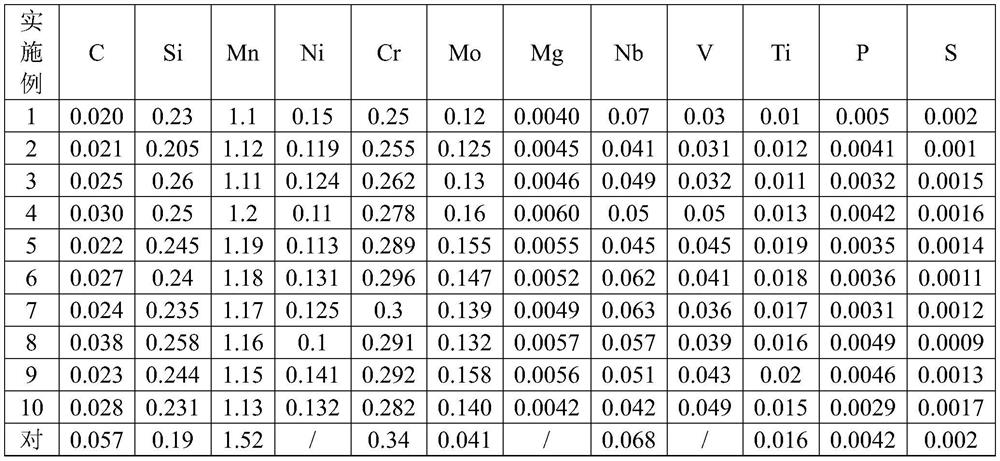

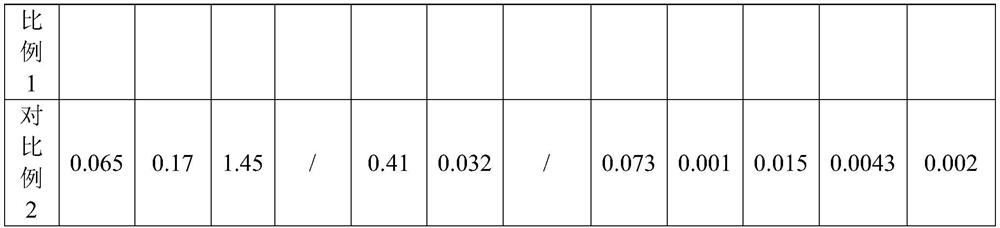

[0039] Table 1 is the value list of each embodiment of the present invention and comparative example;

[0040] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0041] Table 3 is each embodiment of the present invention and comparative example horizontal main mechanical property detection statistical table;

[0042] Table 4 is each embodiment of the present invention and comparative example anti-HIC performance statistical table;

[0043] Table 5 is a statistical table of anti-SSCC performance of each embodiment of the present invention and comparative examples.

[0044] Each embodiment of the present invention is produced according to the following steps:

[0045] 1) Converter smelting, Mg treatment in vacuum, and casting into billet; during vacuum treatment, add Mg wire to the ladle to the design content according to the feeding speed of 6-8m / s;

[0046] 2) Heating the slab, controlling the heating temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com