High-performance optical adhesive as well as preparation method and application thereof

A high-performance, optical adhesive technology, applied in adhesives, non-polymer adhesive additives, N-vinylpyrrolidone copolymer adhesives, etc., can solve the problems of insufficient performance, high light transmittance and low haze of LOCA, High peeling force, high stickiness, poor effect, etc., to achieve fast curing speed, excellent anti-bubble peeling performance, and improve the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0129] The invention provides a method for preparing acrylic acid-free high-performance thermosetting optical glue.

[0130] In the examples of the present application, a Lambda950 ultraviolet-visible spectrophotometer was used for the test of the light transmittance, an Abbe refractometer was used for the test of the refractive index, and a haze meter was used for the test of the haze. The initial adhesion test uses the model CZY-G initial adhesion tester, the holding force test uses the model CZY-GS holding force tester, and the 180°peeling force test uses the universal tensile machine.

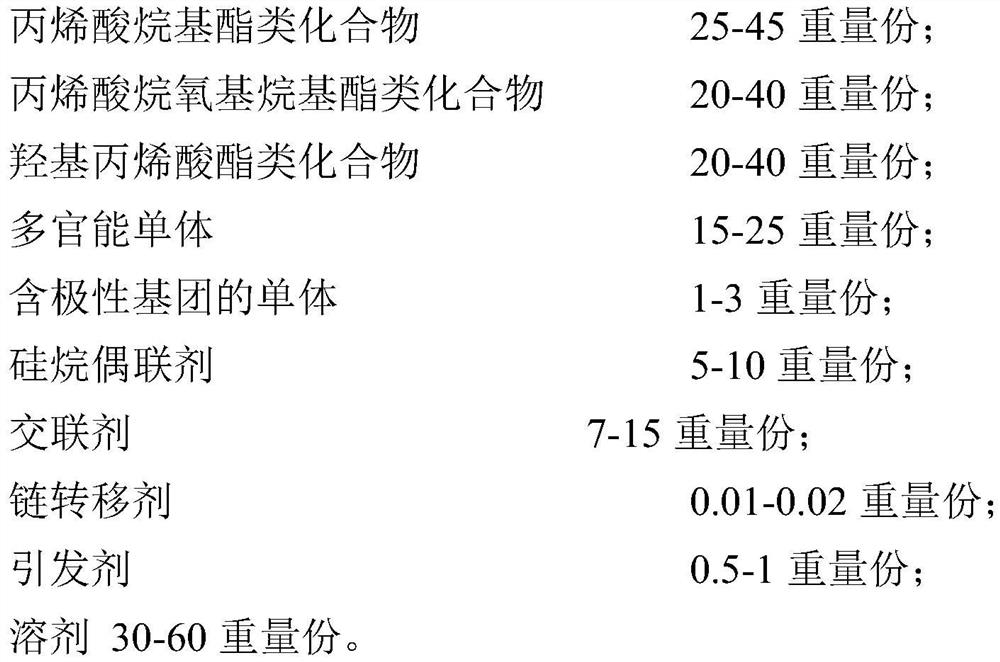

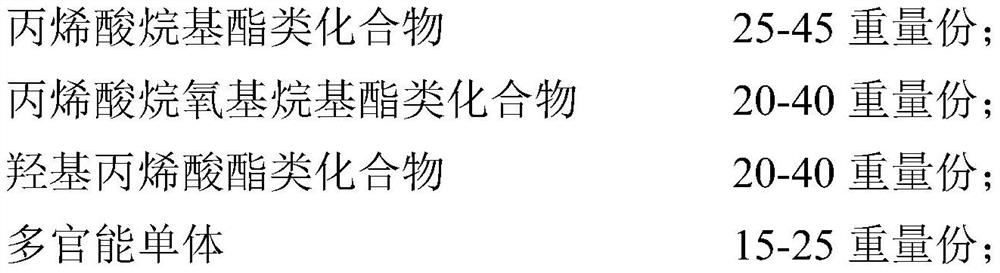

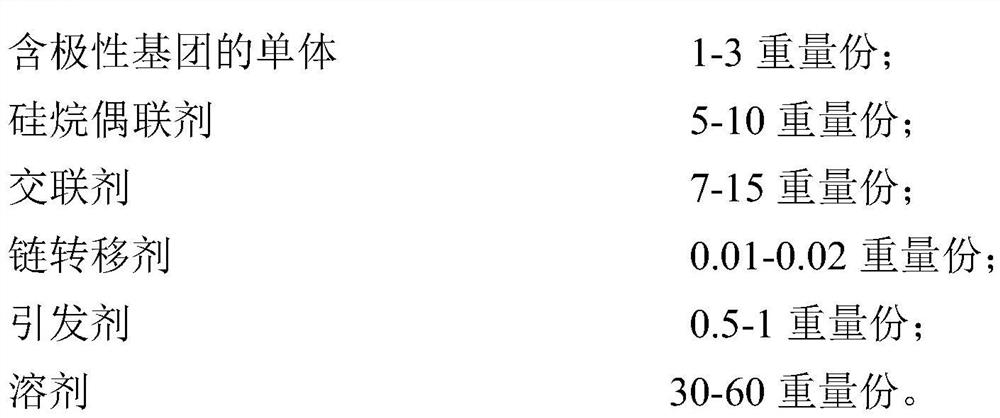

[0131] The heat-curable acrylic optical adhesive with high performance of the present invention is composed of nine components, including acrylic acid containing alkyl (meth)acrylate, alkoxyalkyl (meth)acrylate and hydroxyacrylate as essential monomer components. Class polymers also include polar group-containing monomers, multifunctional monomers, free radical initiators, molecular weight ...

Embodiment 1

[0136] The specific formula of the composition used in the present embodiment is as follows in Table 1:

[0137] Table 1 embodiment 1 (E1) and comparative example (CE) formula list

[0138]

[0139] Note: d is the first letter of the English word drop, which means a drop.

[0140]The specific experimental steps are as follows: butyl acrylate, hydroxyethyl acrylate, 2-methoxyethyl acrylate, neopentyl glycol diacrylate, N-vinyl-2-pyrrolidone and α-thioglycerol were prepared according to the formula Add the amount into a 500mL four-necked flask, and then add 65g of ethyl acetate solvent. The experimental device is equipped with a mechanical stirrer with a digital display function, the rotation speed is 80r / min, a condensed water reflux device, and a nitrogen protection device is installed. The nitrogen flow rate is moderate. , heated in a water bath and gradually raised to 75°C. During the heating process, dissolve azobisisobutyronitrile in acetone, then add the remaining et...

Embodiment 2

[0142] Table 2 embodiment 2 (E2) and comparative example (CE) formula list

[0143]

[0144] Note: d is the first letter of the English word drop.

[0145] The specific experimental steps are as follows: 2-ethylhexyl acrylate, N,N-dimethylacrylamide, methoxytriethylene glycol acrylate, dipentaerythritol hexaacrylate, N-vinyl-2-pyrrolidone and Add 2-mercaptoethanol into a 500mL four-necked flask according to the amount given in the formula, and then add 65g of ethyl acetate solvent. The experimental device is equipped with a mechanical stirrer with digital display function, the speed is 80r / min, condensed water reflux device, and nitrogen protection device, the nitrogen flow rate is moderate, the water bath is heated, and the temperature is gradually raised to 83°C. During the heating process, dissolve AIBN in acetone, then add the remaining ethyl acetate, shake well, add the polytetrafluoroethylene constant pressure dropping funnel, and start adding the initiator solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com