Reflow-soldering plated-through-hole aluminum-based microstrip plate production process

A hole metallization and production process technology, applied in the field of aluminum-based microstrip plate production technology, can solve problems such as poor bonding force of the hole metallized aluminum-based microstrip plate coating, achieve good application value, improve high temperature resistance, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

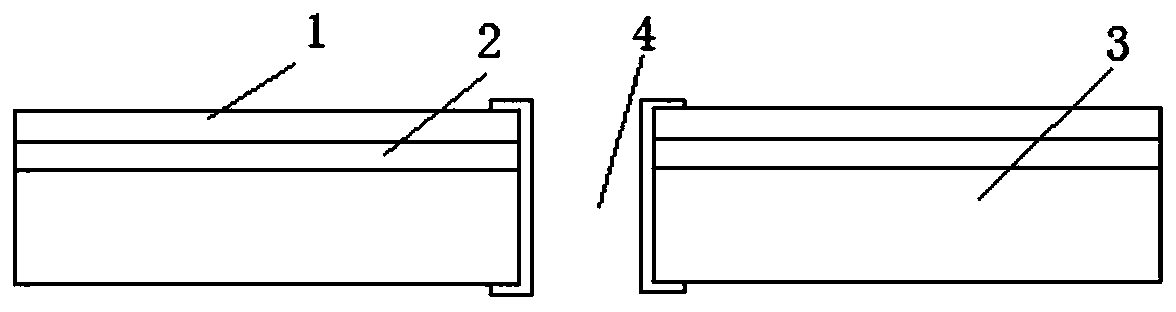

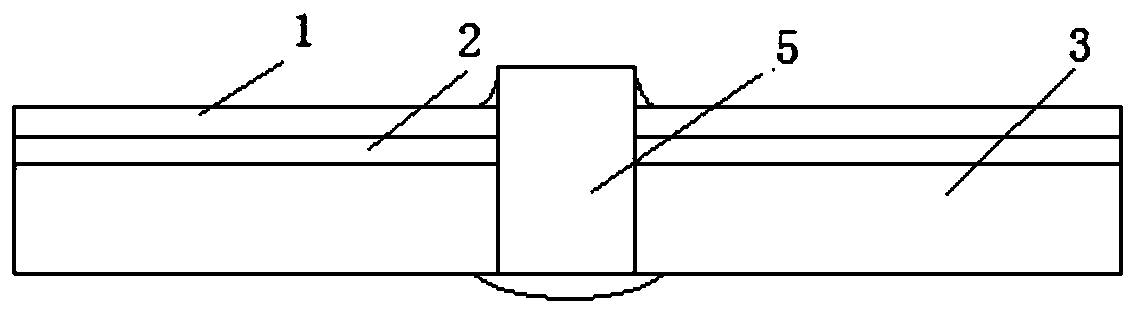

[0026] Such as figure 2 As shown, the base material for the production of hole metallized aluminum-based microstrip board is aluminum-based copper clad laminate, the front side is a copper foil layer 1 for making conductive patterns, the bottom side is a thermally conductive aluminum base layer, and the middle is an insulating layer 2 . The production process flow of the aluminum-based microstrip board of the present invention is: blanking, drilling metallized holes, silk screen solder resist ink on the copper foil surface, three times of zinc dipping and zinc stripping, electroless plating of multi-element nickel alloy, acid copper plating of printed boards, removal of Silk screen solder resist ink, plasma treatment, hole metallization and full board copper plating, graphic transfer, graphic electroplating copper / nickel / gold, etching, silk screen solder mask and cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com