Application of zero-valent iron-loaded biochar in wastewater treatment

A biochar, zero-valent iron technology, applied in metallurgical wastewater treatment, water/sewage treatment, reductive water/sewage treatment, etc., can solve the problems of rising cost, low concentration range of heavy metals and organic compounds, etc., and achieve a good ability to treat wastewater. , the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of biochar loaded with zero-valent iron is as follows:

[0029] Under the condition of inert gas, add biochar into the solution of iron salt and stir evenly, then add reducing agent, which will reduce divalent or ferric iron ions in iron salt to zero-valent iron, that is, elemental iron. The valence iron was loaded on the biochar to obtain a black solid, which is the biochar loaded with zero-valent iron. The black solid was washed with ethanol, and then stored in a brown bottle under a nitrogen atmosphere.

[0030] Wherein, the solvent in the solution is distilled water. The mass ratio of the iron element in the biochar to the iron salt is 1:1-2:1. On the one hand, it ensures that the nano-zero-valent iron can be fully loaded on the bio-char, and on the other hand, it ensures the concentration of the nano-zero-valent iron in the prepared material. The content is higher.

[0031] The black solid was washed with ethanol to prevent the oxidation of...

Embodiment 1

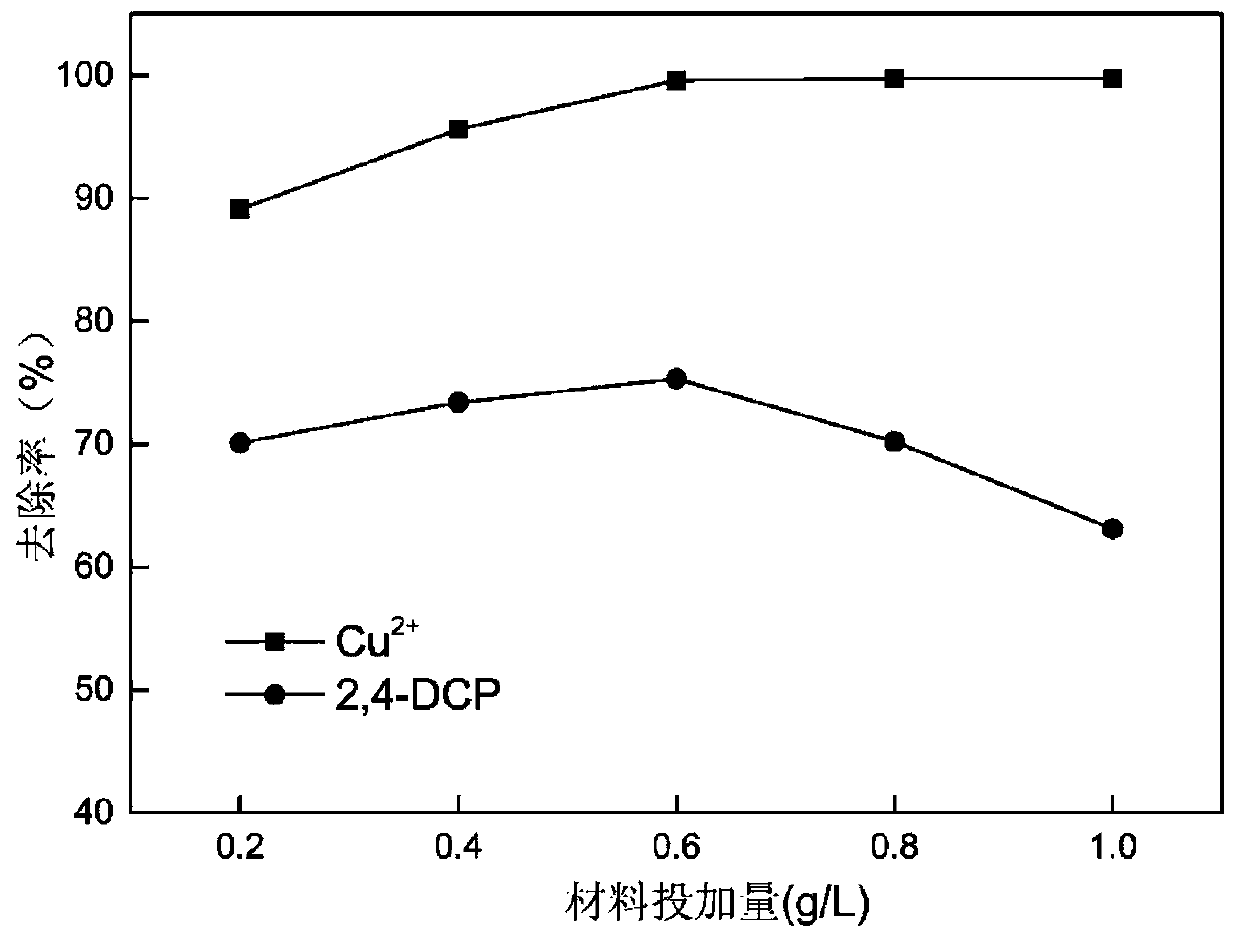

[0047] Co-treatment of electroplating wastewater and organic wastewater using biochar loaded with zero-valent iron, that is, to Cu 2+ or Ni 2+ The mixed water with 2,4-DCP is added with biochar loaded with zero-valent iron to remove heavy metals and organic pollutants.

[0048] The specific steps are: use a 1000ml beaker as the reactor, and treat 20ml of Cu 2+ (4000mg / L) and 380ml of 2,4-DCP (20mg / L) mixed solution (organic pollution wastewater: electroplating wastewater=19:1, v:v), Cu in the final mixed solution 2+ and 2,4-DCP concentrations were 200mg / L and 19mg / L, and the pH of the mixed water was adjusted to 5. Then add the biochar loaded with zero-valent iron prepared in the laboratory, so that the content in the mixed water body is 0.6g / L. The solution in the reactor was stirred at a rotational speed of 150 rpm, and the reaction time was 60 min. The specific results are shown in Table 1.

Embodiment 2

[0050] A 1000ml beaker is used as the reactor, and the processing object is 400ml Cu 2+ (200mg / L), adjust the pH of the water to 5. Then add the biochar loaded with zero-valent iron prepared in the laboratory, so that the concentration in the mixed water body is 0.6g / L. The solution in the reactor was stirred at a rotational speed of 150 rpm, and the reaction time was 60 min. The specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com