Lithium ion battery electrolyte and preparation method and application thereof

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of lowering thermal decomposition temperature, increasing internal resistance, poor high-temperature performance of lithium-ion batteries, etc., and achieving the effect of suppressing the combustion chain reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

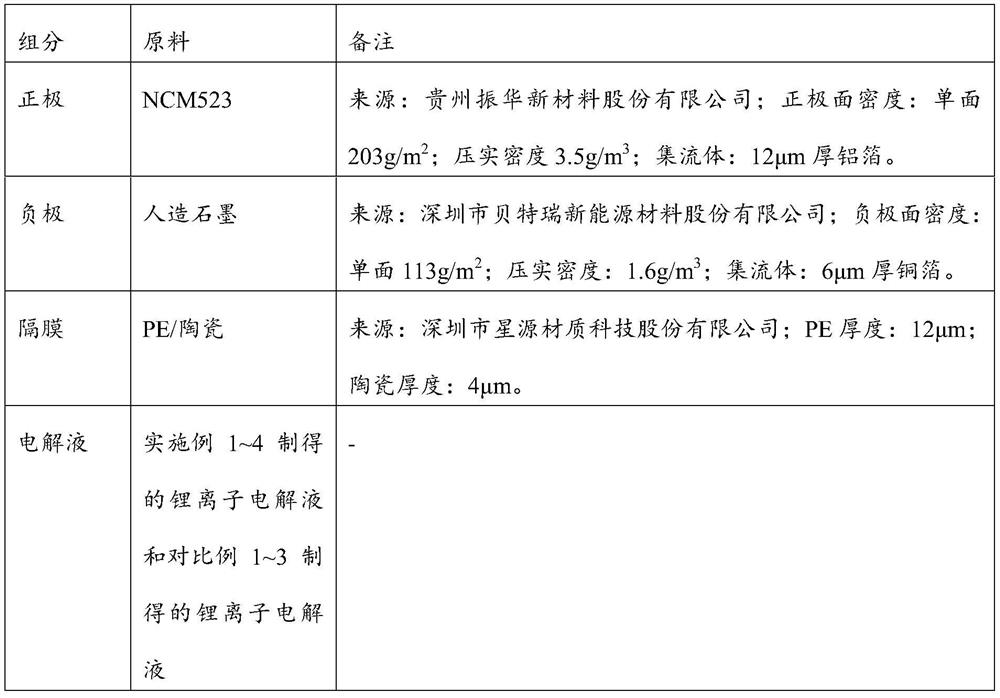

Examples

Embodiment 1

[0071] This embodiment provides a lithium-ion battery electrolyte and a preparation method thereof.

[0072] The lithium ion battery electrolyte of the present embodiment is made up of the preparation raw material of following mass fraction:

[0073] Lithium salt: lithium trifluoromethanesulfonimide;

[0074] Solvent: the mass ratio of dimethyl carbonate, diethyl carbonate and ethylene carbonate is 1:1:1;

[0075] Additives: dimethyl methyl phosphate, bis(2,2,2-trifluoroethyl) carbonate and diphenyldimethoxysilane;

[0076] The molar concentration of lithium salt in the electrolyte is 1mol / L;

[0077] The mass fraction of dimethyl methyl phosphate in the electrolyte is 1%;

[0078] The mass fraction of bis(2,2,2-trifluoroethyl) carbonate in the electrolyte is 2%;

[0079] The mass fraction of diphenyldimethoxysilane in the electrolyte is 0.2%;

[0080] Solvent balance.

[0081] This embodiment also provides a preparation method for the electrolyte, comprising the followi...

Embodiment 2

[0093] This embodiment is a lithium-ion battery electrolyte and a preparation method thereof.

[0094] The lithium ion battery electrolyte of the present embodiment is made up of the preparation raw material of following mass fraction:

[0095] Lithium salt: lithium trifluoromethanesulfonimide;

[0096] Solvent: the mass ratio of dimethyl carbonate, diethyl carbonate and ethylene carbonate is 1:1:1;

[0097] Additives: dimethyl methyl phosphate, bis(2,2,2-trifluoroethyl) carbonate and diphenyldimethoxysilane;

[0098] The molar concentration of lithium salt in the electrolyte is 1mol / L;

[0099] The mass fraction of dimethyl methyl phosphate in the electrolyte is 2%;

[0100] The mass fraction of bis(2,2,2-trifluoroethyl) carbonate in the electrolyte is 1.8%;

[0101] The mass fraction of diphenyldimethoxysilane in the electrolyte is 0.4%;

[0102] Solvent balance.

[0103] The preparation method of this embodiment is the same as in Example 1.

Embodiment 3

[0105] This embodiment is a lithium-ion battery electrolyte and a preparation method thereof.

[0106] The lithium ion battery electrolyte of the present embodiment is made up of the preparation raw material of following mass fraction:

[0107] Lithium salt: lithium trifluoromethanesulfonimide;

[0108] Solvent: the mass ratio of dimethyl carbonate, diethyl carbonate and ethylene carbonate is 1:1:1;

[0109] Additives: dimethyl methyl phosphate, bis(2,2,2-trifluoroethyl) carbonate and diphenyldimethoxysilane;

[0110] The molar concentration of lithium salt in the electrolyte is 1mol / L;

[0111] The mass fraction of dimethyl methyl phosphate in the electrolyte is 3%;

[0112] The mass fraction of bis(2,2,2-trifluoroethyl) carbonate in the electrolyte is 1.5%;

[0113] The mass fraction of diphenyldimethoxysilane in the electrolyte is 0.4%;

[0114] Solvent balance.

[0115] The preparation method of this embodiment is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com