UV cured transparent and flame-retardant coating

A flame retardant coating and transparent technology, applied in fire retardant coatings, epoxy resin coatings, coatings, etc., can solve problems such as reduced transparency, reduced coating curing speed, and affected appearance, and achieves high transparency, good adhesion, Fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

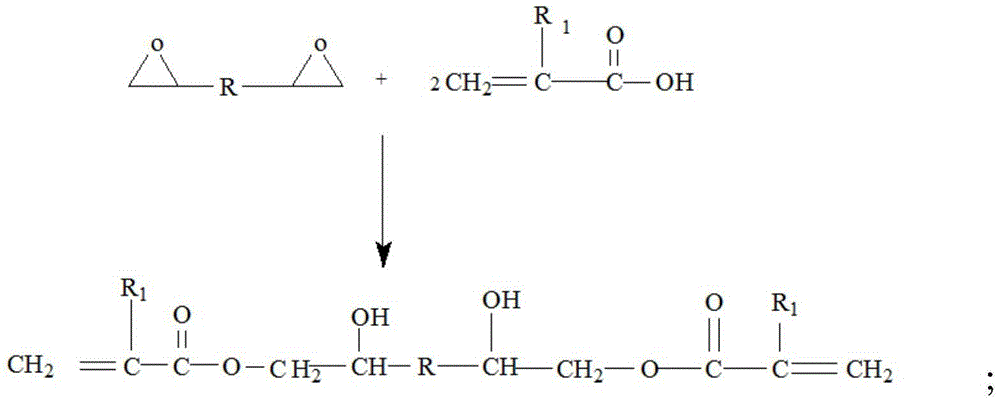

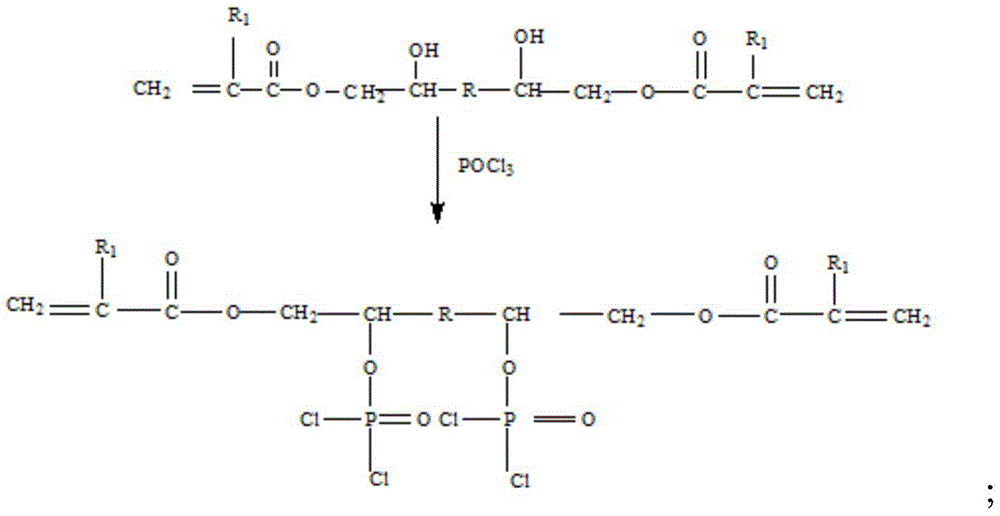

Method used

Image

Examples

Embodiment 1

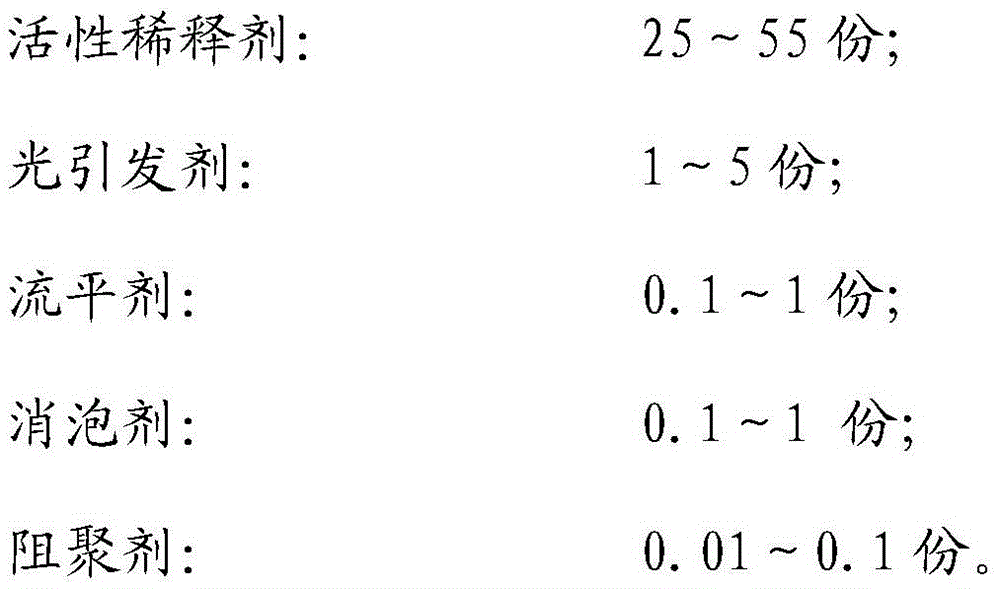

[0042] The parts by weight of UV-curable transparent flame-retardant coating: 40 parts of phosphorus-modified bisphenol A epoxy acrylic resin, 25 parts of 2-hydroxyethyl methacrylate phosphate, 2 parts of 1-hydroxycyclohexyl phenyl ketone, BYK358N0. 1 part, EFKA20200.1 part, p-hydroxyanisole 0.01 part, stir well.

Embodiment 2

[0044] The parts by weight of UV-curable transparent flame-retardant coating: 70 parts of phosphorus-modified bisphenol A epoxy acrylic resin, 55 parts of alkyl acrylate phosphate, 3 parts of 1-hydroxycyclohexyl phenyl ketone, BYK3330.01 parts, BYK0550. 1 part, 0.1 part of p-hydroxyanisole, stir well.

Embodiment 3

[0046] Weight parts of UV curable transparent flame retardant coating: 70 parts of phosphorus modified novolac epoxy acrylic resin, 55 parts of alkyl acrylate phosphate, 3 parts of 1-hydroxycyclohexyl phenyl ketone, 0.01 parts of Levlip9760, 0.1 parts of EFKA2028 , 0.1 part of hydroquinone, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com