Cooling device for high-temperature powdery material and using method thereof

A powdery material and cooling device technology, applied in fixed tubular conduit components, heat exchange equipment, direct contact heat exchangers, etc., can solve cooling operations with high infrastructure and operating costs, large cooling gas consumption, secondary mine Phase transition and other issues, to achieve the effect of low operating cost and equipment cost, guaranteed cooling effect, and less moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

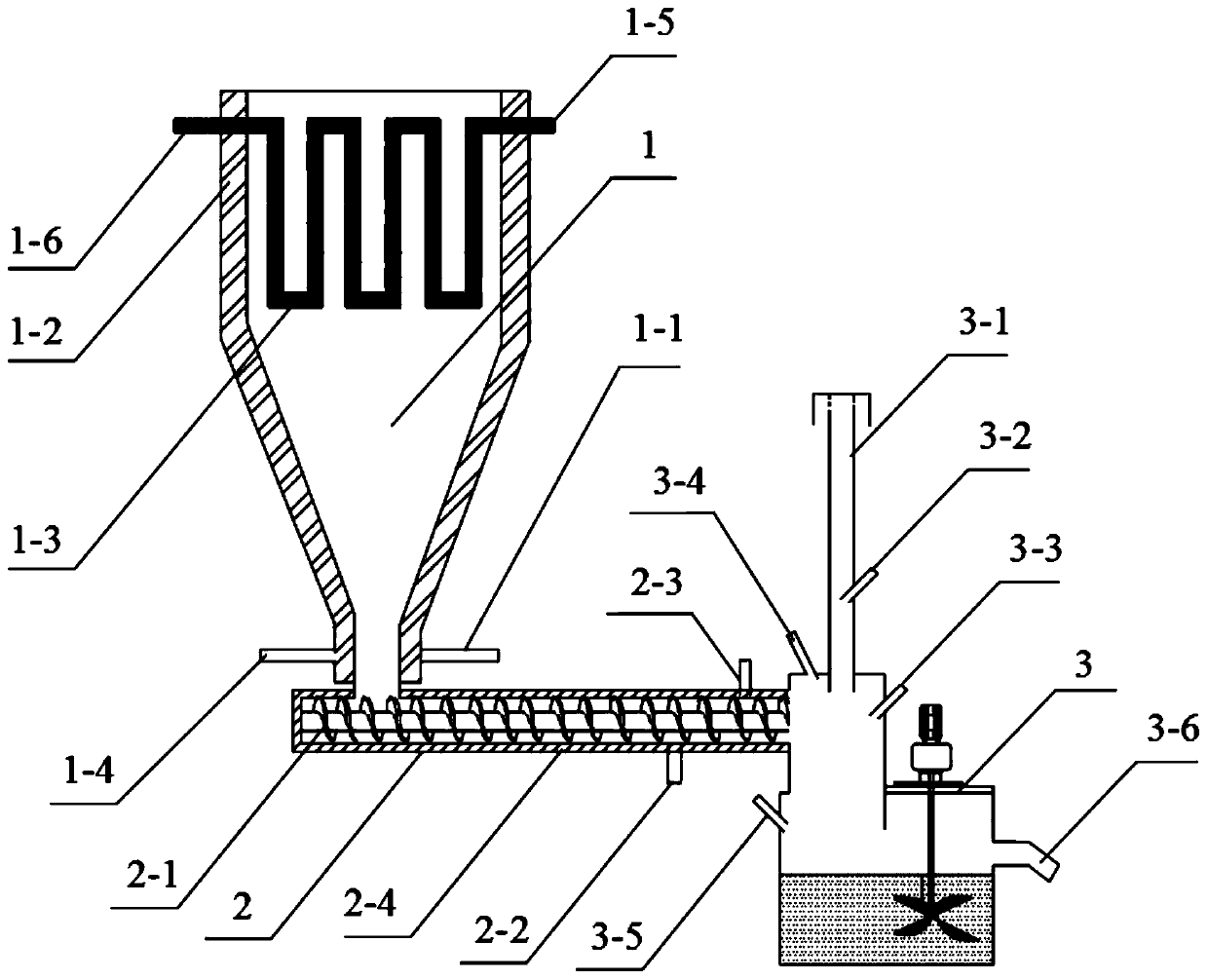

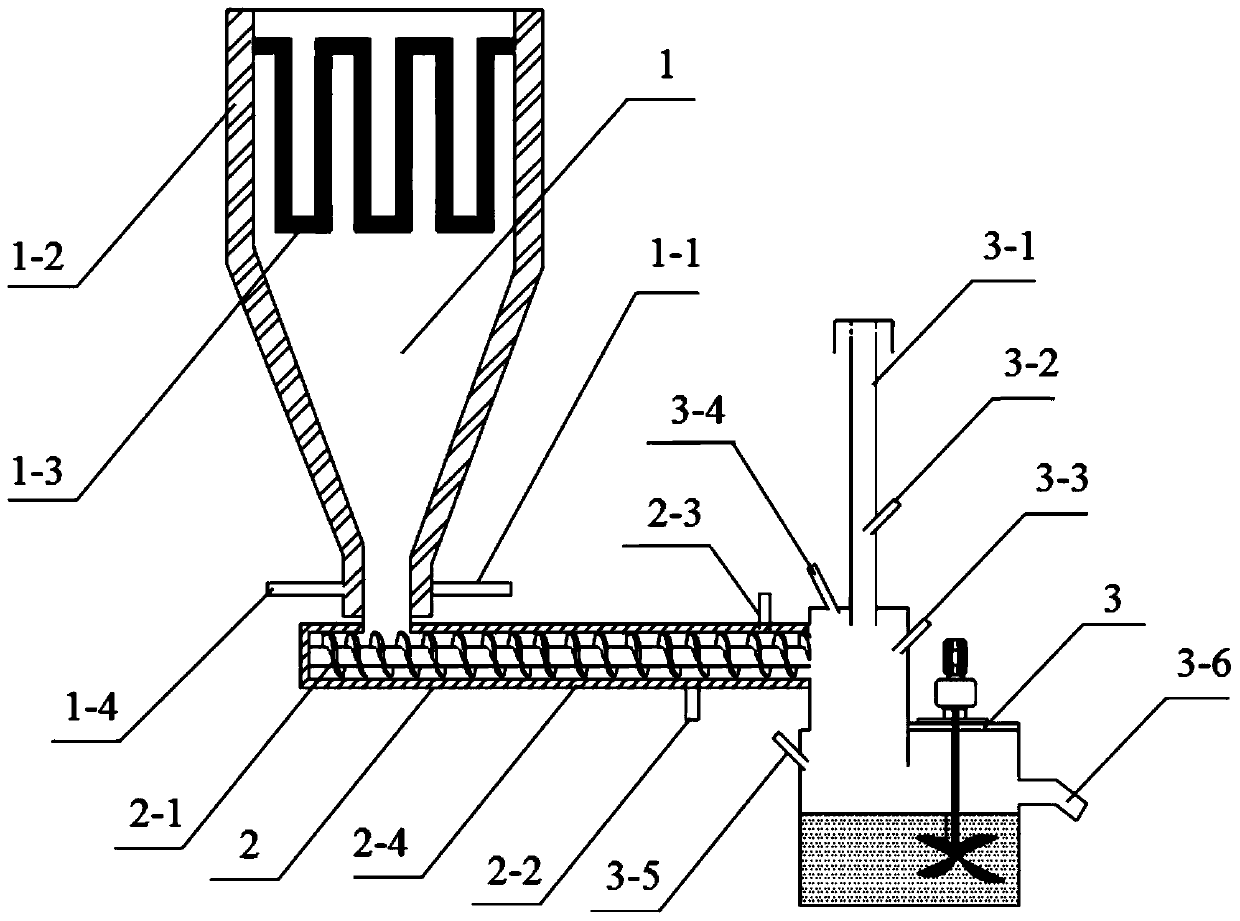

[0035] A cooling device for high-temperature powdery materials, such as figure 1 As shown, it includes a cooling silo 1, a spiral cooler 2, a mixing tank 3, and associated connecting pipes and valves. The cooling bin 1 of this embodiment is installed directly below the outlet of the fine ore high-temperature pretreatment device, and is connected to the outlet of the fine ore high-temperature pretreatment material through a high-temperature-resistant pipeline, and the outlet of the cooling bin 1 passes through a high-temperature-resistant pipeline It is connected to the feed port of the spiral cooler 2, the discharge port of the spiral cooler 2 is connected to the feed port of the mixing tank 3, and the cooling pulp outlet 3-6 of the mixing tank 3 is connected to the subsequent processing process through pipelines.

[0036] The outer wall of the cooling silo 1 of the present embodiment is provided with a silo cooling water jacket 1-2, and the silo cooling water jacket 1-2 is pr...

Embodiment 2

[0045] A cooling device for high-temperature powdery materials, such as figure 1 As shown, it includes a cooling silo 1, a spiral cooler 2, a mixing tank 3, and associated connecting pipes and valves. The cooling bin 1 of this embodiment is installed directly below the outlet of the fine ore high-temperature pretreatment device, and is connected to the outlet of the fine ore high-temperature pretreatment material through a high-temperature-resistant pipeline, and the outlet of the cooling bin 1 passes through a high-temperature-resistant pipeline It is connected to the feed port of the spiral cooler 2, the discharge port of the spiral cooler 2 is connected to the feed port of the mixing tank 3, and the cooling pulp outlet 3-6 of the mixing tank 3 is connected to the subsequent processing process through pipelines.

[0046] The outer wall of the cooling silo 1 of the present embodiment is provided with a silo cooling water jacket 1-2, and the silo cooling water jacket 1-2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com