A polyimide-based graphene composite foam material with multi-level structure and its preparation

A graphene composite and polyimide-based technology, applied in the field of porous foam materials, can solve the problems of poor electromagnetic wave reflection loss, narrow microwave absorption frequency bandwidth, and lack of electromagnetic absorption capacity, etc., to achieve heat resistance and good insulation The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

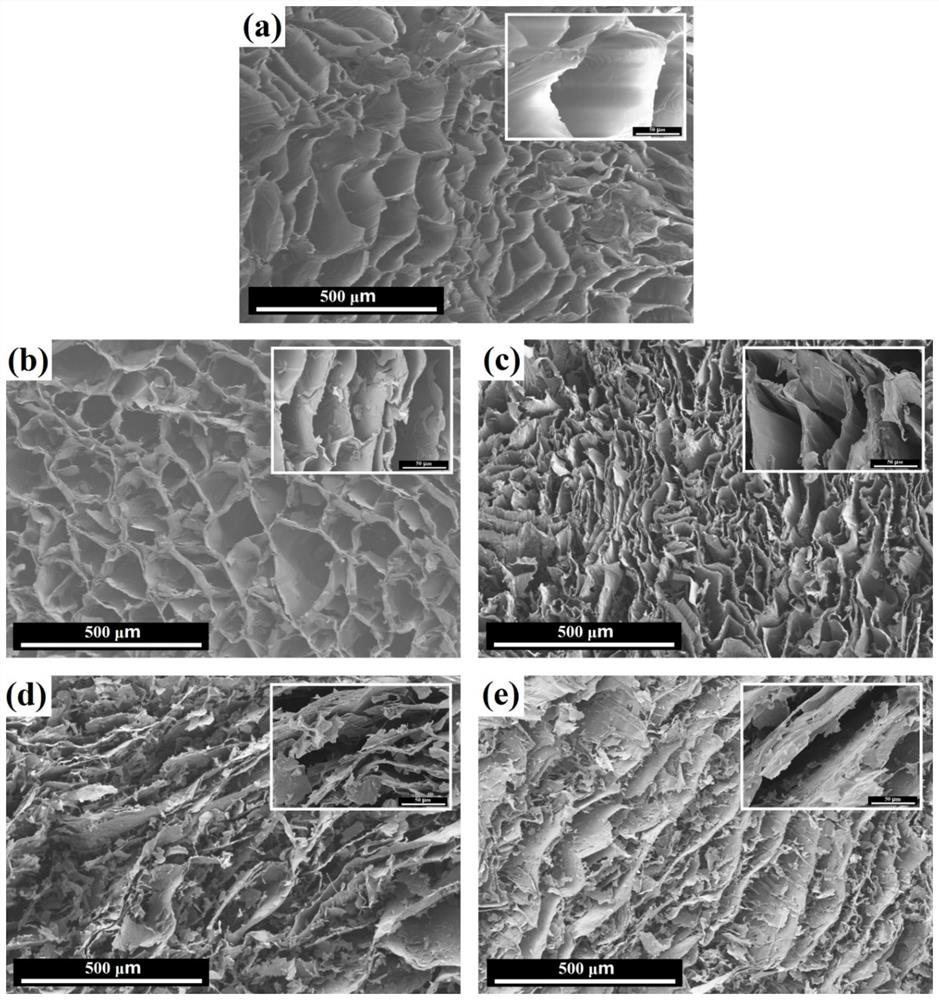

[0039] Preparation of tertiary polyimide-graphene / polyimide-graphene composite foam (PI-GP 1 / 2 -rGO)

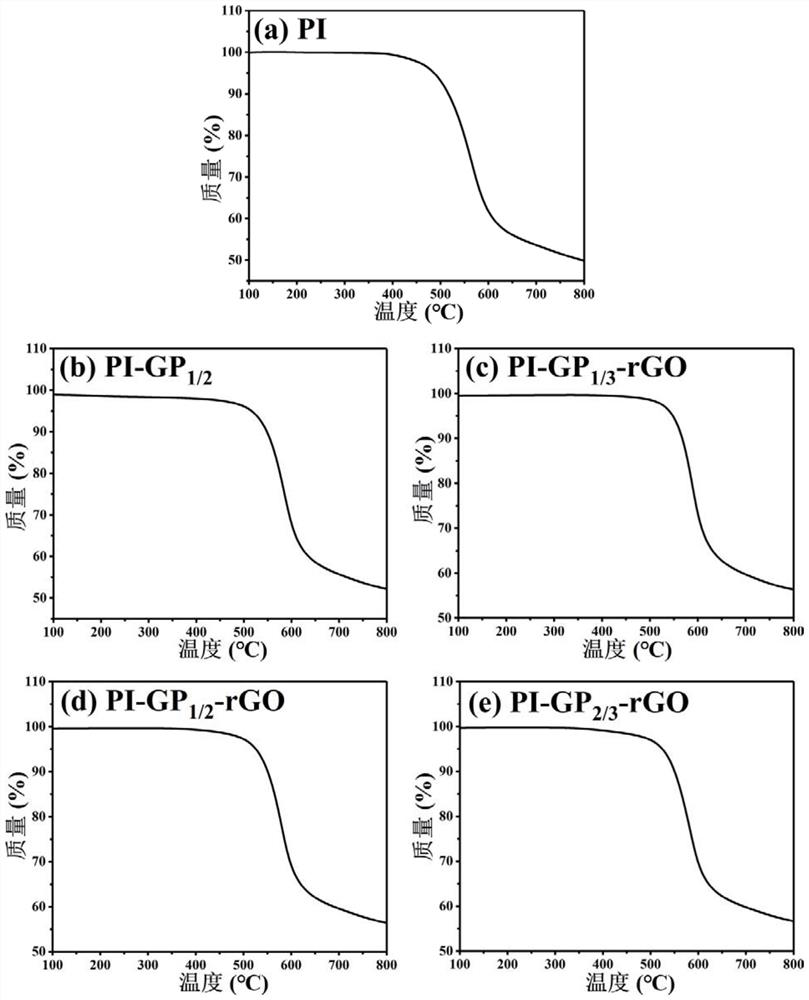

[0040] (1) Preparation of polyimide foam (PI)

[0041] Using N,N'-dimethylacetamide as a solvent, the solid content of 15 % polyamic acid. The specific process is as follows: Dissolve 8.0096g of 4,4'-diaminodiphenyl ether in 95.57g of N,N'-dimethylacetamide, add 8.8556g of pyromellitic dianhydride, and react in an ice-water bath at 0°C 5h. Then, 4.0476 g of triethylamine was added, and the reaction was continued for 5 h to prepare a water-soluble polyamic acid solution with a solid content of 15%. The prepared water-soluble polyamic acid is suspended on a high place and dripped into deionized water for precipitation in the form of flowing silk, and the organic solvent is replaced, and then the precipitate is washed with deionized water for 2-3 times, and finally the vacuum is used to 1 Pa, a vacuum freeze dryer with a temperature of -80°C is used for freeze-drying, and t...

Embodiment 2

[0049] Preparation of tertiary polyimide-graphene / polyimide-graphene composite foam (PI-GP 2 / 3 -rGO)

[0050] (1) prepare polyimide foam (PI): preparation method is identical with embodiment 1;

[0051] (2) Preparation of two-stage polyimide-graphene / polyimide composite foam (PI-GP 1 / 2 ): Compared with Example 1, the mixed solutions of graphene oxide and polyamic acid loaded with different concentration ratios. The specific operation method is as follows: prepare a graphene oxide dispersion with a concentration of 4 mg / mL under ultrasonic conditions; dissolve water-soluble polyamic acid prepolymer and triethylamine in water to prepare a concentration of 2 mg / mL and 1 mg / mL respectively A mixture of polyamic acid solution and triethylamine solution. The prepared graphene oxide dispersion and polyamic acid / triethylamine mixed solution were mixed under magnetic stirring. The polyimide foam (PI) prepared in the step (1) is put into the above mixed solution, and impregnated and...

Embodiment 3

[0054] Preparation of tertiary polyimide-graphene / polyimide-graphene composite foam (PI-GP 1 / 3 -rGO)

[0055] (1) prepare polyimide foam (PI): preparation method is identical with embodiment 1;

[0056] (2) Preparation of two-stage polyimide-graphene / polyimide composite foam (PI-GP 1 / 2 ): Compared with Example 1, the mixed solutions of graphene oxide and polyamic acid loaded with different concentration ratios. The specific operation method is as follows: prepare a graphene oxide dispersion with a concentration of 4 mg / mL under ultrasonic conditions; dissolve water-soluble polyamic acid prepolymer and triethylamine in water to prepare a concentration of 8 mg / mL and 4 mg / mL respectively A mixture of polyamic acid solution and triethylamine solution. The prepared graphene oxide dispersion and polyamic acid / triethylamine mixed solution were mixed under magnetic stirring. The polyimide foam (PI) prepared in the step (1) is put into the above mixed solution, and impregnated and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com