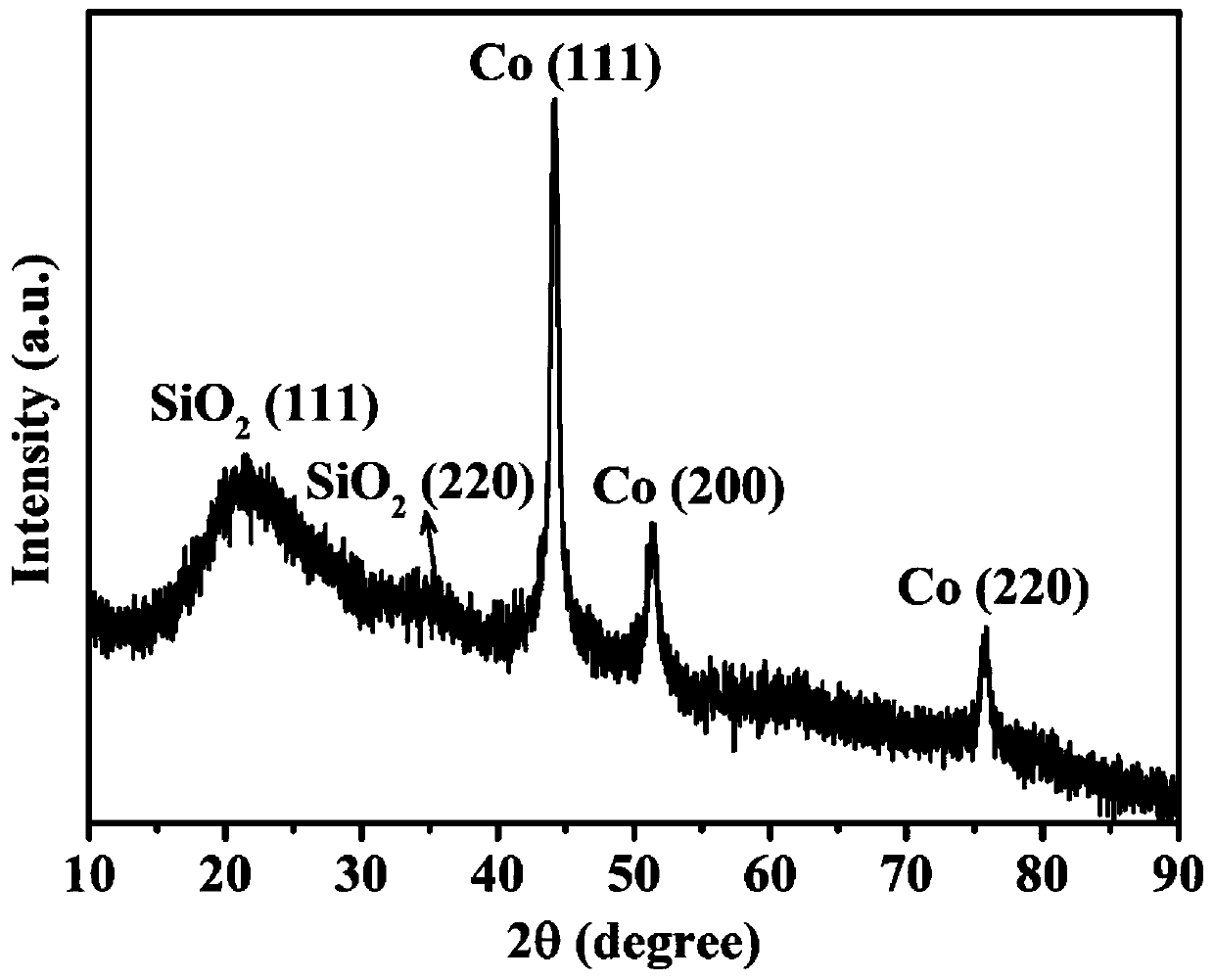

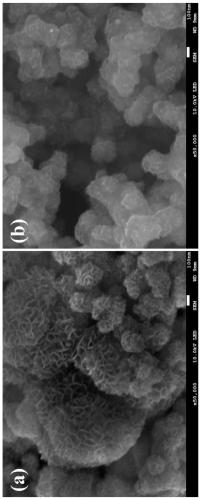

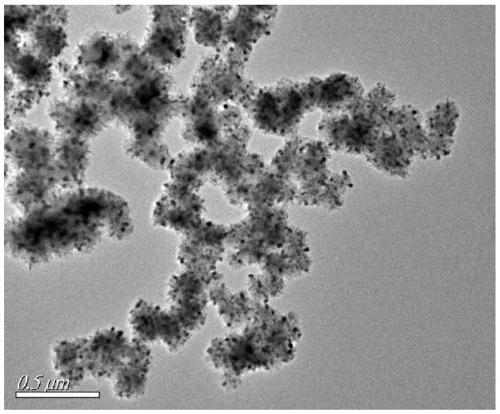

Co cluster/SiO2 composite material and preparation method and application thereof

A composite material and cluster technology, applied in the field of electrocatalysis, can solve problems such as instability of metal nanoclusters, and achieve the effects of improving electrochemical stability, small anode OER overpotential, and a wide range of synthetic raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 (best embodiment)

[0043] (1) Synthesis of nano-copper sulfide aqueous solution: pipette 180mL of deionized water into a 250mL round bottom flask, weigh 34mg of copper chloride dihydrate (0.2mmol) and 40mg of trisodium citrate dihydrate (0.136 mmol) into it , magnetically stirred at room temperature to form a light blue solution evenly; weigh 0.1201g of sodium sulfide nonahydrate, add deionized water to dissolve and set the volume in a 50mL volumetric flask (the concentration of sodium sulfide nonahydrate is 10 mmol / L), and then 20mL of Na 2 S·9H 2 O aqueous solution was added dropwise to the above solution, and magnetic stirring was continued at room temperature for 5 minutes, and the reaction mixture turned dark brown; the mixture was moved to a constant temperature water bath, heated to 90°C, continued to heat and react for 15 minutes, and finally obtained The dark green copper sulfide nanoparticle solution was cooled in an ice-water bath, and the sol...

Embodiment 2

[0047] Embodiment 2 (preferred, different heat treatment temperatures)

[0048] (1) Synthesis of nano-copper sulfide aqueous solution: pipette 180mL of deionized water into a 250mL round bottom flask, weigh 34mg of copper chloride dihydrate (0.2mmol) and 40mg of trisodium citrate dihydrate (0.136 mmol) into it , magnetically stirred at room temperature to form a light blue solution evenly; weigh 0.1201g of sodium sulfide nonahydrate, add deionized water to dissolve and set the volume in a 50mL volumetric flask (the concentration of sodium sulfide nonahydrate is 10 mmol / L), and then 20mL of Na 2 S·9H 2 O aqueous solution was added dropwise to the above solution, and magnetic stirring was continued at room temperature for 5 minutes, and the reaction mixture turned dark brown; the mixture was moved to a constant temperature water bath, heated to 90°C, continued to heat and react for 15 minutes, and finally obtained The dark green copper sulfide nanoparticle solution was cooled ...

Embodiment 3

[0052] Embodiment 3 (preferred, different heat treatment temperatures)

[0053] (1) Synthesis of nano-copper sulfide aqueous solution: pipette 180mL of deionized water into a 250mL round bottom flask, weigh 34mg of copper chloride dihydrate (0.2mmol) and 40mg of trisodium citrate dihydrate (0.136 mmol) into it , magnetically stirred at room temperature to form a light blue solution evenly; weigh 0.1201g of sodium sulfide nonahydrate, add deionized water to dissolve and set the volume in a 50mL volumetric flask (the concentration of sodium sulfide nonahydrate is 10 mmol / L), and then 20mL of Na 2 S·9H 2 O aqueous solution was added dropwise to the above solution, and magnetic stirring was continued at room temperature for 5 minutes, and the reaction mixture turned dark brown; the mixture was moved to a constant temperature water bath, heated to 90°C, continued to heat and react for 15 minutes, and finally obtained The dark green copper sulfide nanoparticle solution was cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com