P-surface metal preparation method of ridge-type GaAs-based laser with deep groove

A laser, deep trench technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as caps, difficult to meet, different corrosion rates, etc., to prevent metal faults, shorten production cycles, and reduce consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a P-face metal of a ridge-type GaAs-based laser with deep grooves, comprising the steps of:

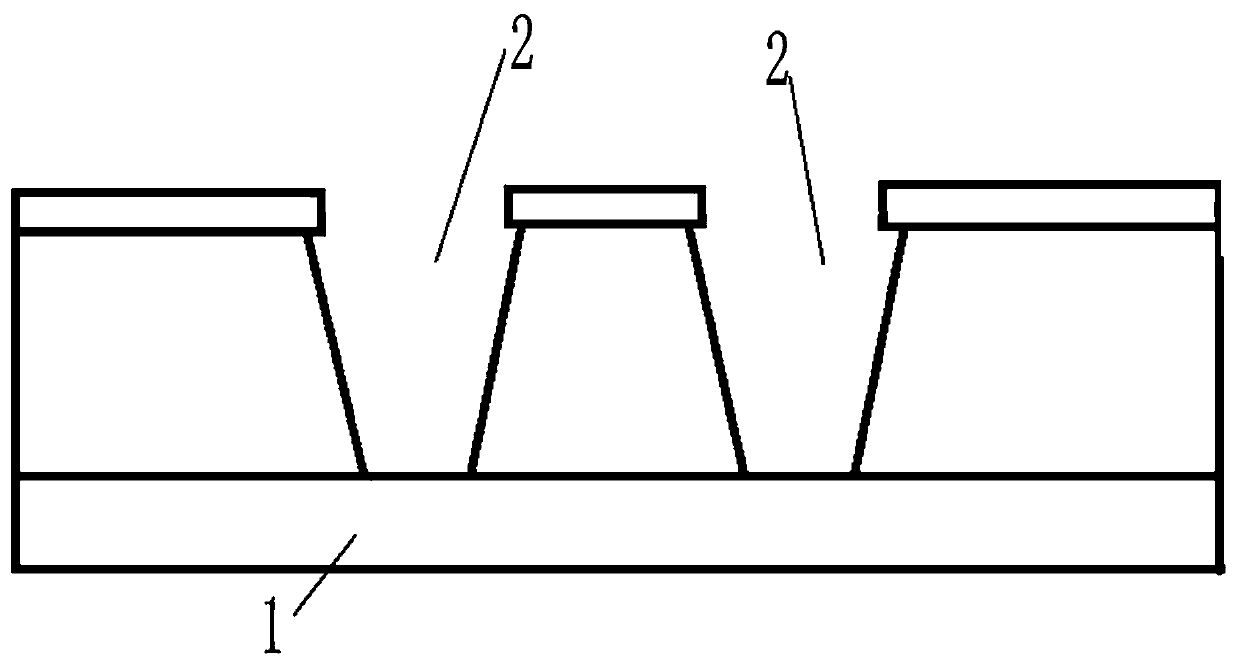

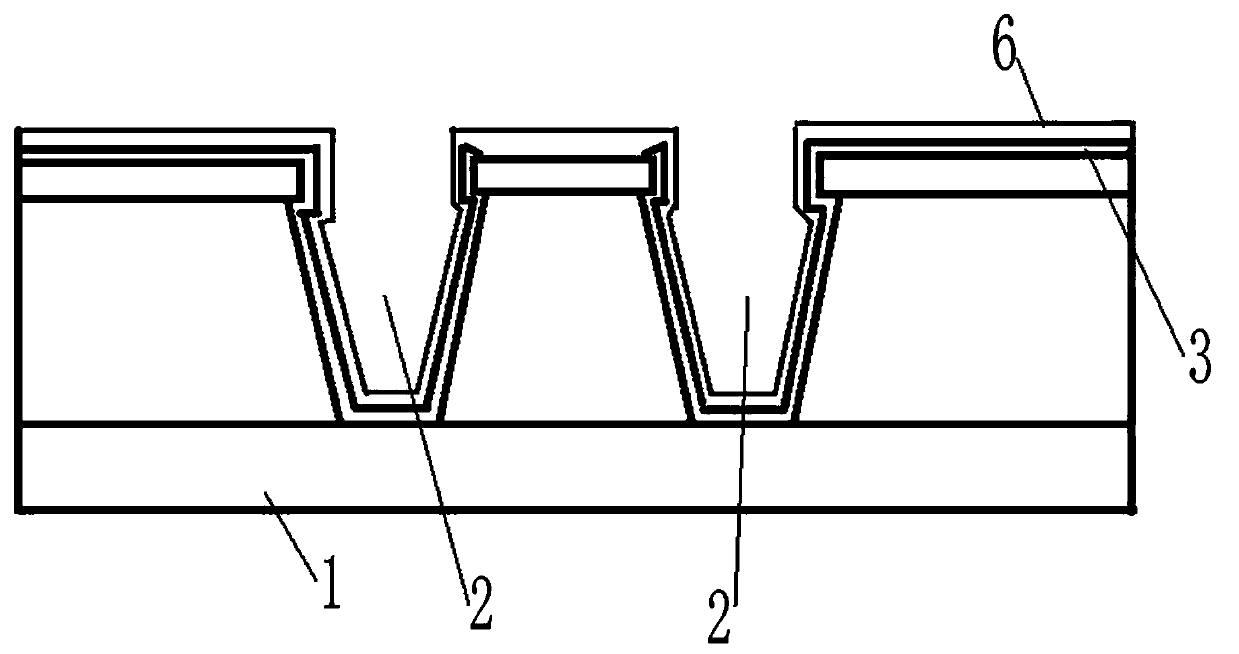

[0032] a) Prepare the epitaxial wafer 1. The epitaxial wafer includes substrate, N confinement layer, quantum well active area, AlGaInP layer and GaAs layer from bottom to top, and etches a ridge-shaped light-emitting area on the AlGaInP layer and GaAs layer, and the ridge-shaped light-emitting area Ridge grooves 2 are formed on both sides of the region;

[0033] b) preparing a layer of silicon dioxide passivation film 3 on the surface of the epitaxial wafer 1 other than the ridge-shaped light-emitting region using PECVD equipment and photolithography;

[0034] c) Spin-coat a layer of negative photoresist on the silicon dioxide passivation film 3, and prepare a P electrode pattern by photolithography and development;

[0035] d) growing a metal layer 6 on the silicon dioxide passivation film 3 according to the region of the P electrode pattern, the metal...

Embodiment 1

[0042] The depth of the ridge groove 2 in step a) is greater than 2 μm and less than 8 μm.

Embodiment 2

[0044] The thickness of the silicon dioxide passivation film 3 in step b) is 1000-2000 angstroms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com