Preparation method of strontium titanate nano material with adjustable morphology

A nanomaterial, strontium titanate technology, applied in the field of preparation of strontium titanate nanomaterials, can solve the problems of low orientation, narrow range, performance deterioration, etc., and achieve the effects of high photocatalytic efficiency, simple preparation process, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

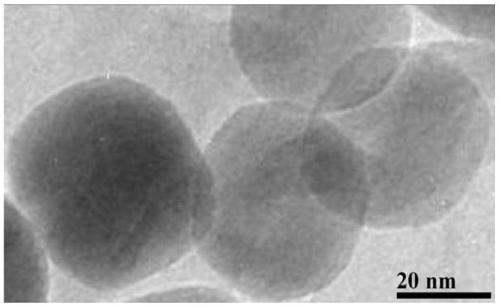

Embodiment 1

[0027] 1) During the synthesis of strontium titanate nanoparticles, 1 mmol of strontium nitrate was dissolved in 5 mL of deionized water, 12.5 mmol of sodium hydroxide was dissolved in 5 mL of deionized water, and 1 mmol of n-butyl titanate was dissolved in 5 mL of anhydrous butanol 1.5mmol oleic acid was dissolved in 5mL anhydrous butanol, and strontium nitrate aqueous solution, sodium hydroxide aqueous solution, n-butyl titanate anhydrous butanol solution, oleic acid anhydrous butanol solution were prepared;

[0028] 2) Mix the configured solutions together and then transfer the resulting solution to a 50mL polytetrafluoroethylene-lined stainless steel autoclave;

[0029] 3) Seal the autoclave, then heat at 200°C for 24h, and cool to room temperature naturally after the reaction;

[0030] 4) The obtained product was centrifuged at 3000 round / min for 5 minutes, the supernatant was discarded, and the precipitate was ultrasonically cleaned in acetone, alcohol, and deionized wat...

Embodiment 2

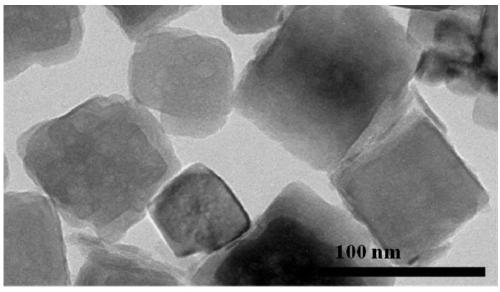

[0032] Using the same process as in Example 1, the difference is that the amount of oleic acid added in step 1) of Example 1 is changed to 0.5 mmol, and other conditions remain the same.

Embodiment 3

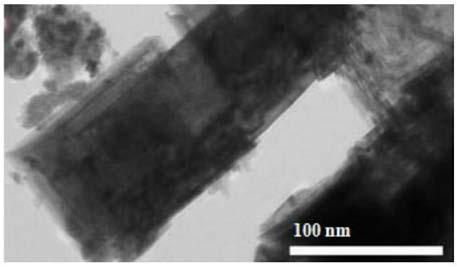

[0034] The same process as in Example 1 is adopted, the difference is that the amount of oleic acid added in step 1) of Example 1 is changed to 3 mmol, and other conditions remain the same.

[0035] By adjusting the content of oleic acid, the shape of micelles formed by the self-assembly of oleic acid molecules in the reaction system can be changed, and the SrTiO formed in the initial stage of the reaction 3 Oriented assembly of nanocrystallites in micelles of different shapes, resulting in SrTiO with different morphologies 3 nanomaterials.

[0036] Test the SrTiO prepared in 1~3 respectively 3 In order to compare the catalytic performance of nanomaterials, commercially available strontium titanate nanopowder (Aldrich, 30nm) was also used to degrade methylene blue, a common dye, under the same conditions. Degradation effect such as Figure 4 As can be seen from the figure, the synthesized SrTiO of the present invention 3 The catalytic activity of the nanomaterials is highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com