TWIP steel laser welding method based on high-entropy alloy intermediate layer

A high-entropy alloy, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of mechanical properties decline, serious burn-out segregation of weld elements, and restricted use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The composition of the intermediate layer selected in this embodiment is CoCrFeNi high-entropy alloy, and its atomic ratio is Co:Cr:Fe:Ni=1:1:1:1.

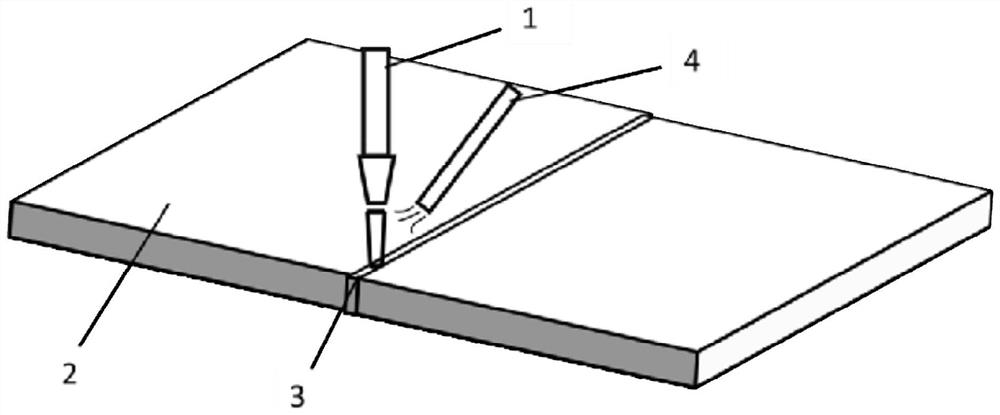

[0056] A TWIP steel laser welding method based on a high-entropy alloy intermediate layer, the specific steps are as follows:

[0057] The Co, Cr, Fe, and Ni of the metal raw material particles (purity of 99.99%) are proportioned according to the atomic ratio of 1:1:1:1, weighed, and repeatedly smelted by an arc melting furnace for 5 times. ingot. Under the protection of argon, the ingot was homogenized and heat-treated at 1200°C for 24h, and then water quenched. Then, use wire cutting technology to cut the high-entropy alloy into metal sheets with a thickness of 0.5mm, and the remaining dimensions are the same as the size of the surface to be welded. Significant oxide layer;

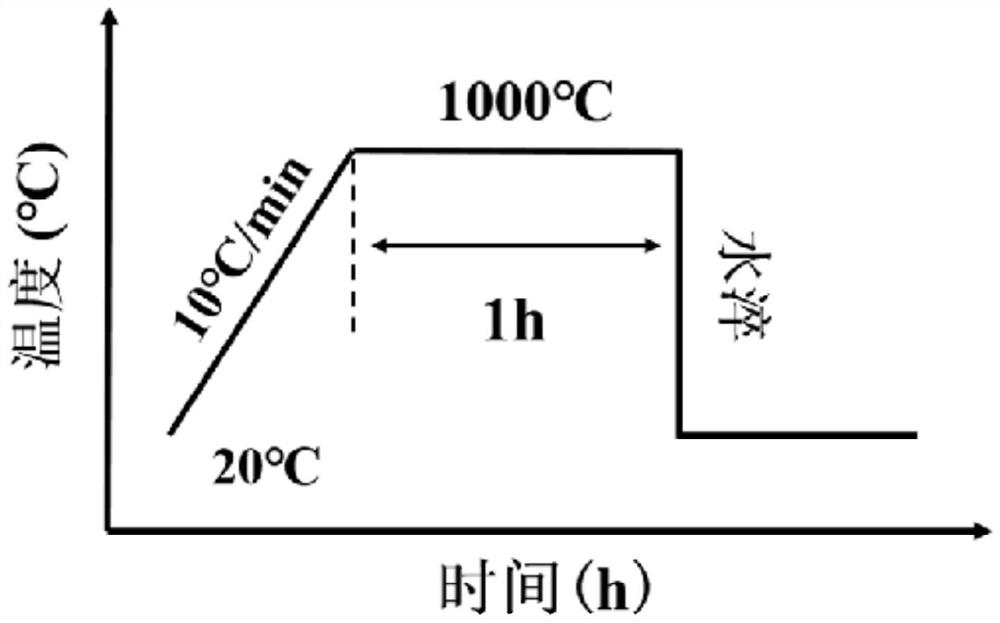

[0058] Put the TWIP steel to be welded into an electric heating furnace for annealing treatment, the heating rate is 10°C / min, the holding temper...

Embodiment 2

[0064] The welding method of this embodiment is basically the same as that of Embodiment 1, except that the high-entropy alloy used is CoCrNi, and its atomic ratio is Co:Cr:Ni=1:1:1.

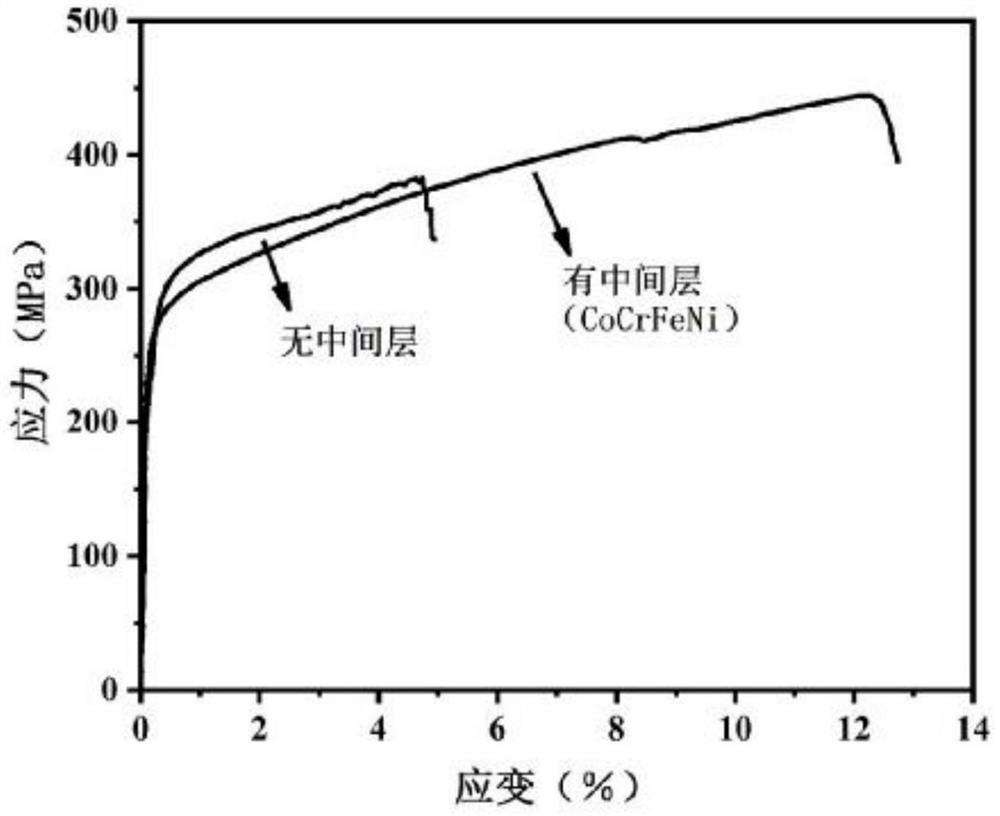

[0065] The TWIP steel welded joint with CoCrNi as the intermediate layer and the directly welded joint of the reference TWIP steel are tested, and the obtained stress-strain curve is as follows: Figure 4 shown.

[0066] Depend on Figure 4 It can be seen that the tensile strength of the welded joint that is directly laser welded without adding the intermediate layer is 382.6MPa and the elongation is 4.74%, while the tensile strength of the welded joint that is laser welded by adding CoCrNi high entropy alloy in Example 2 is 384.7 MPa, the elongation is 6.83%. It can be seen that CoCrNi high-entropy alloy flakes are used as the welding intermediate layer of TWIP steel in this example, and the obtained welded joint has higher strength and better elongation.

[0067] In the welding method provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com