Polymer solid electrolyte and preparation method and application thereof

A technology of solid electrolytes and polymers, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of difficult preparation of inorganic solid electrolytes, short circuit, low working power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] The present invention also provides a method for preparing a polymer solid electrolyte, the method comprising the following steps:

[0079] Step (S1): dissolving the rubber in an organic solvent and stirring evenly to form a solution A;

[0080] Step (S2): dissolving oligomers of acrylate and its derivatives, lithium salts, plasticizers, photoinitiators, and small molecule additives in an organic solvent, stirring evenly to form a solution B, and performing ultraviolet light on the solution B irradiation;

[0081] Step (S3): Mix solution A with solution B after ultraviolet light irradiation to form a uniform solution, add a thermal initiator, stir evenly, apply it on the surface of the base film, and perform hot-pressing crosslinking treatment to prepare the polymer solid electrolyte.

[0082] In a specific embodiment of the present invention, the step (S1) specifically includes dissolving the rubber in an organic solvent and stirring for 10-24 hours, so that the rubb...

Embodiment 1

[0109] (1) Dissolve 1g of natural rubber in 50mL of acetonitrile solution, stir well to form a solution A with a concentration of 20mg / mL;

[0110] (2) 3.4g of lithium perchlorate, 10g of polyethylene glycol methyl ether methacrylate, 6.8g of propylene carbonate, and 2.6g of succinonitrile were dissolved in 100mL of acetonitrile, and 0.04g of 2-hydroxyl - 2-Methyl-1-phenylacetone, stirred evenly to form solution B, and then triggered under ultraviolet light irradiation for 30min;

[0111] (3) The prepared solution A and solution B were mixed, and then 0.04 g of azobisisobutyronitrile was added, and then coated on the centrifugal membrane, and the membrane was formed by hot pressing at 100° C. for 6 hours under a pressure of 0.1 MPa.

[0112] (4) The prepared polymer solid-state electrolyte is matched with lithium iron phosphate positive electrode sheet and lithium metal negative electrode sheet, and a lithium-ion battery is manufactured by lamination process.

Embodiment 2

[0114] (1) 0.4g butadiene rubber was dissolved in 50mL of ethyl acetate solution, stirred evenly to form a solution A with a solution concentration of 8mg / mL;

[0115] (2) 2.32g of lithium bis(trifluoromethanesulfonate)imide, 12.2g of polyethylene glycol acrylate, 4.64g of ethylene carbonate and 2.64g of malononitrile were added and dissolved in 100mL of acetonitrile , add 0.1g of 1-hydroxycyclohexyl phenyl ketone, stir evenly to form solution B, and then trigger 30min under ultraviolet light irradiation;

[0116] (3) Add the prepared solution A to the solution B, then add 0.1 g of azobisisoheptanonitrile, and then coat it on the centrifugal membrane, use 0.5MPa pressure, heat press at 200°C for 6h, and form a film;

[0117] (4) The prepared polymer solid-state electrolyte is matched with lithium cobalt oxide positive electrode sheet and lithium metal negative electrode sheet, and a lithium ion battery is made by winding process.

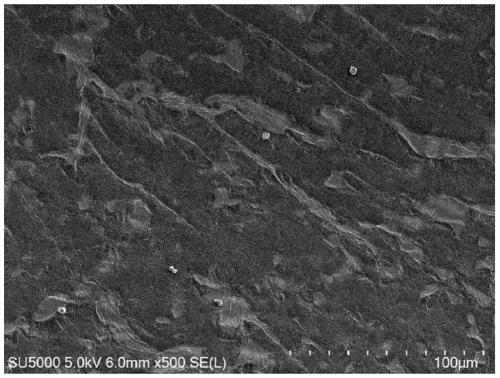

[0118] figure 1 SEM of the polymer solid el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com