Method for separating C8 aromatic hydrocarbon isomeride mixture

A technology for isomers and C8 aromatic hydrocarbons, which is applied in the field of separation of C8 aromatic hydrocarbon isomer mixtures, can solve the problems of poor molecular recognition ability and low adsorption capacity, and achieves adjustable pore structure and high separation. Selective, adjustable force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Weigh 4,4'-bipyridine and dissolve it in ethylene glycol, weigh 0.27g Cu(BF 4 ) 2 ·xH 2 O and 0.20g (NH 4 ) 2 SiF 6 Dissolve in water, mix the above two solutions under stirring, then heat to 60-70°C for 1-12 hours, the obtained product SIFSIX-1-Cu is filtered and washed with methanol, and then vacuum activated at 25-80°C 2 After ~6 hours, the activated SIFSIX-1-Cu material was obtained.

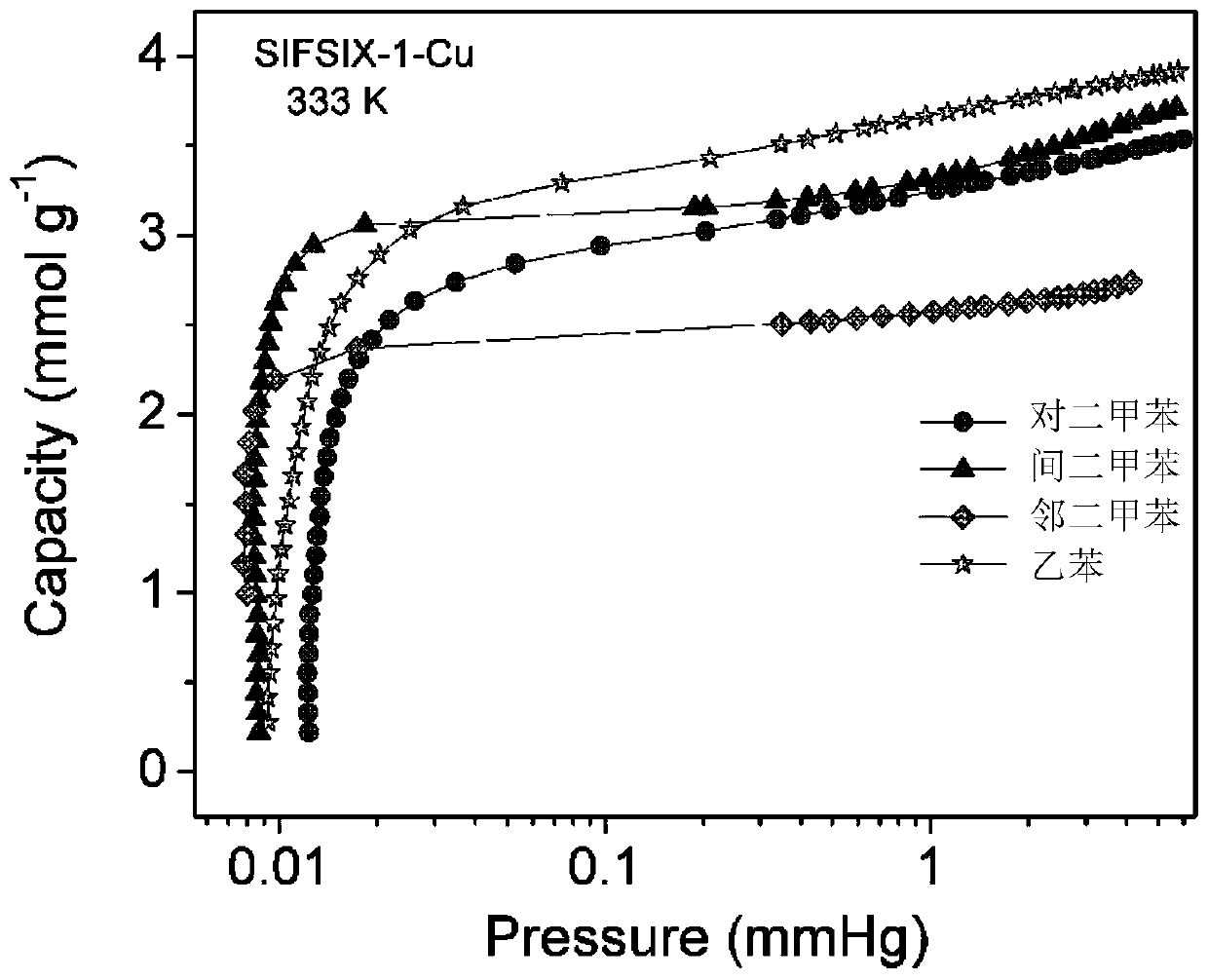

[0052] The adsorption isotherms of p-xylene isomers and ethylbenzene of SIFSIX-1-Cu material at 333K are as follows figure 1 shown.

Embodiment 2

[0054] The SIFSIX-1-Cu prepared in Example 1 is loaded into a 5cm adsorption column, and nitrogen bubbling is used to obtain a mixture containing p-xylene, m-xylene, o-xylene, and ethylbenzene (mass ratio is 1:1:1:1) Then the mixed gas is passed into the adsorption column at a flow rate of 20-40mL / min. The operating temperature of the adsorption column is 60 degrees Celsius. The breakthrough data curve is as follows: figure 2 As shown, high-purity p-xylene gas can be obtained in the effluent gas.

Embodiment 3

[0056] Nitrogen bubbling is used to obtain a three-component mixed gas containing p-xylene, m-xylene, and o-xylene (mass ratio 1:1:1), and then the mixed gas is passed into the embodiment at a flow rate of 20-40mL / min For the adsorption column in 2, the operating temperature of the adsorption column is 60 degrees Celsius, and high-purity p-xylene (greater than 99.9%, mass percent) gas can be obtained in the effluent gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com