Method for testing folding life of folding electric kettle

A testing method and technology for electric kettles, which are applied to the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of difficulty in the folding test of electric kettles, and there is no special detection method and equipment for folding kettles. Wide application range, high safety, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

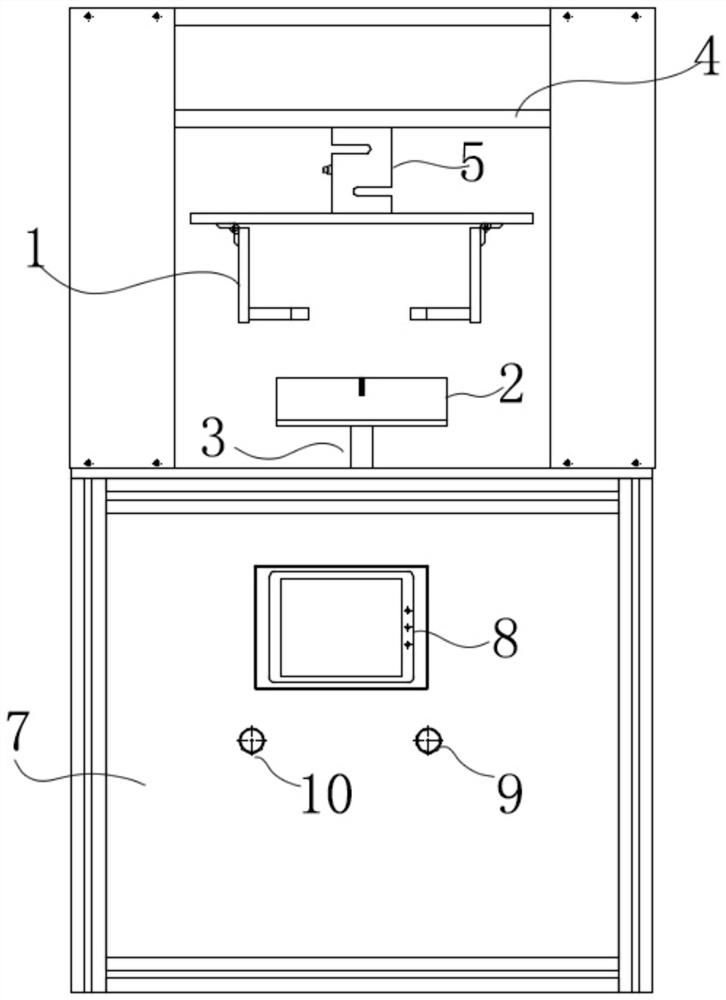

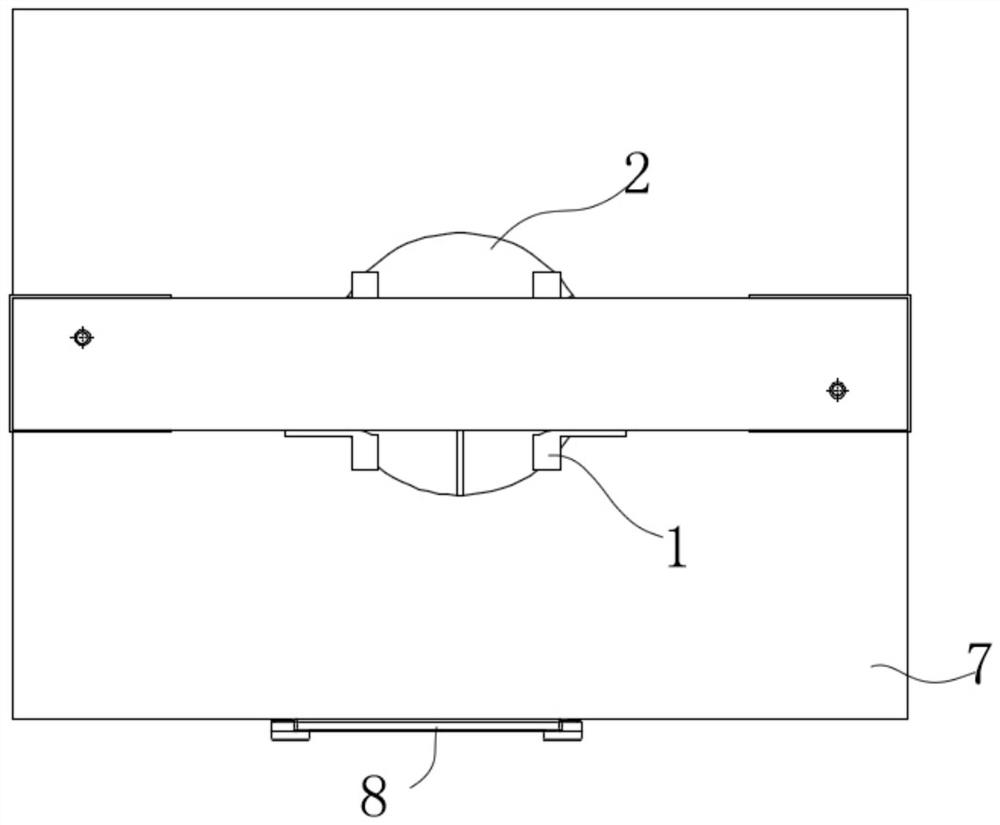

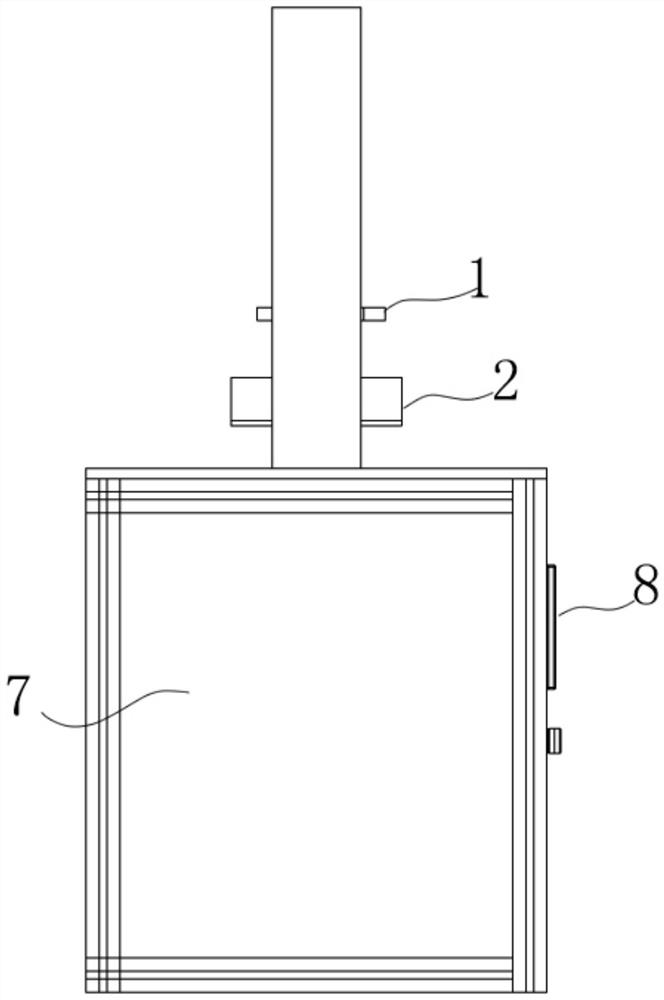

[0044] Such as Figure 1 to Figure 9 As shown, a test device for folding life of a folding electric kettle includes:

[0045] The pot top clamp seat 4 is used to install the removable pot top clamp 1. The pot top clamp seat 4 is connected to a mechanical arm 4 that can move back and forth periodically, and the mechanical arm 4 is connected to the output part of the cylinder, that is, the push rod of the cylinder. , the cylinder is a multi-position multi-way cylinder with adjustable output force, intake and exhaust speed, and stroke distance. In this embodiment, a three-position five-way cylinder is used. The stroke distance of the push rod of the cylinder can be adjusted. The port and the exhaust port are connected to different control air sources to adjust the output force of the cylinder, the speed of intake and exhaust, and then control the folding rate of the mechanical arm and the magnitude of the force applied during each folding process.

[0046] The pot bottom clamp s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com