Condenser microphone with hole in diaphragm and manufacturing method thereof

A capacitive microphone and the technology of its manufacturing method, which are applied in the field of microphones, can solve the problems of not easily thermally deformed, unstable device structure, and electrode shedding, and achieve the effects of not easily thermally deformed, economical preparation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

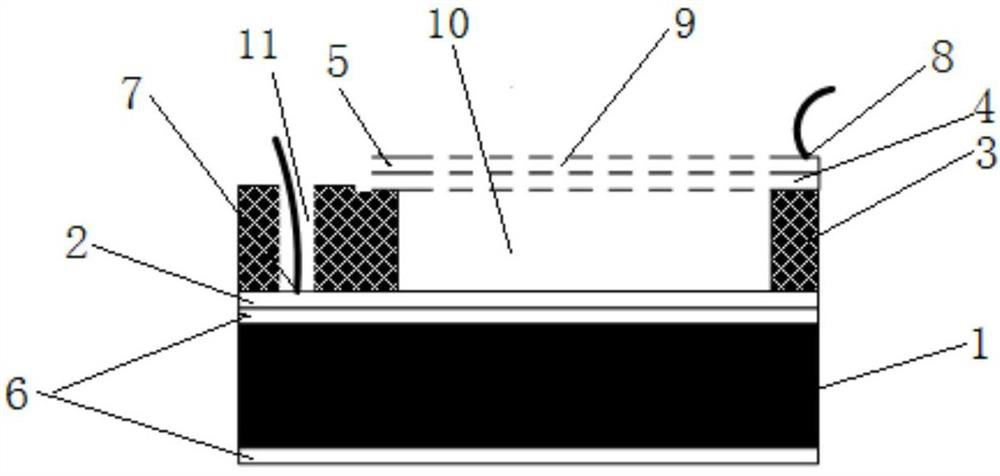

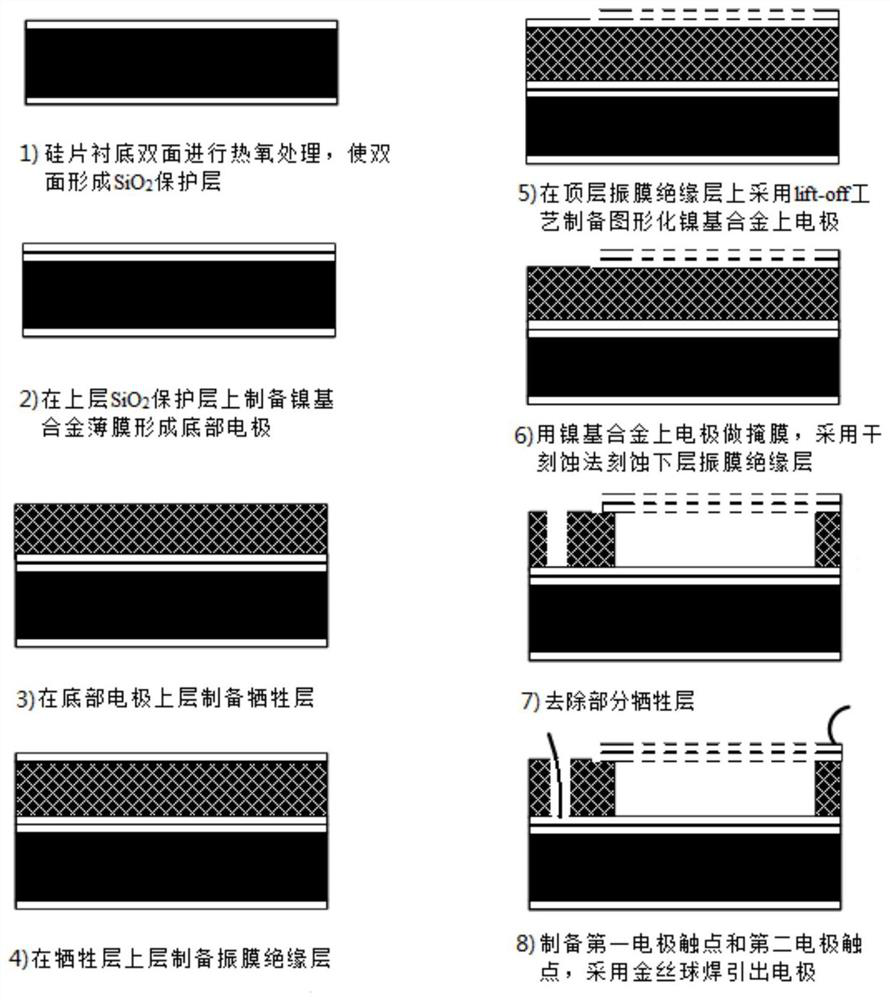

[0040] Such as figure 1As shown, a kind of capacitive microphone with holes in the diaphragm provided by the present invention includes a substrate 1, a composite diaphragm, a sacrificial layer 3, a protective layer 6 and a back plate 2; the substrate 1 is a silicon wafer; the composite diaphragm Including the diaphragm insulating layer 4 and the upper electrode 5, the upper electrode 5 is located on the upper layer of the diaphragm insulating layer 4, the composite diaphragm has good tensile stress and flexibility; the sacrificial layer 3 is located between the back plate 2 and the composite diaphragm , the back pole plate 2 and the composite diaphragm are isolated, there is an oscillation cavity 10 between the back pole plate 2 and the composite diaphragm, the composite diaphragm is provided with several acoustic holes 9, and the acoustic holes 9 on the diaphragm communicate with the oscillation cavity cavity 10; the back plate 2 and the composite diaphragm form a plate capa...

Embodiment 2

[0050] In this embodiment, the structure of the capacitive microphone with a hole in the diaphragm is basically the same as in Embodiment 1, the main difference being the material and thickness of the sacrificial layer 3, the material and thickness of the diaphragm insulating layer 4, and the back plate. 2 and the material and thickness of the upper electrode 5 and the thickness of the protective layer 6.

[0051] In this embodiment, the material of the sacrificial layer 3 is silicon nitride, and the thickness of the sacrificial layer 3 is 5 μm; the material of the diaphragm insulating layer 4 is silicon dioxide, and the thickness of the diaphragm insulating layer 4 is 0.2 μm; the nickel-based alloy is nickel-chromium-molybdenum The thickness of the nickel-chromium-molybdenum alloy back plate 2 is 0.5 μm; the thickness of the nickel-chromium-molybdenum alloy upper electrode 5 is 0.5 μm; the thickness of the protective layer 6 is 1.5 μm.

[0052] Since metal nickel itself has a...

Embodiment 3

[0055] In this embodiment, the structure of the capacitive microphone with a hole in the diaphragm is basically the same as in Embodiment 1, the main difference being the material and thickness of the sacrificial layer 3, the material and thickness of the diaphragm insulating layer 4, and the back plate. 2 and the material and thickness of the upper electrode 5 and the thickness of the protective layer 6.

[0056] In this embodiment, the material of the sacrificial layer 3 is silicon dioxide, and the thickness of the sacrificial layer 3 is 10 μm; the material of the diaphragm insulating layer 4 is silicon nitride, and the thickness of the diaphragm insulating layer 4 is 3 μm; the nickel-based alloy is nickel-copper alloy; The thickness of the nickel-copper alloy back plate 2 is 1 μm; the thickness of the nickel-copper alloy upper electrode 5 is 1 μm; the thickness of the protective layer 6 is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com