Force-induced responsive polymer with single hybrid network structure

A network structure and responsive technology, applied in the field of mechano-responsive polymers, mechano-responsive polymers and their realization, can solve the problem of inability to obtain self-healing performance, poor material toughness, inability to monitor and warn materials Function and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

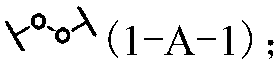

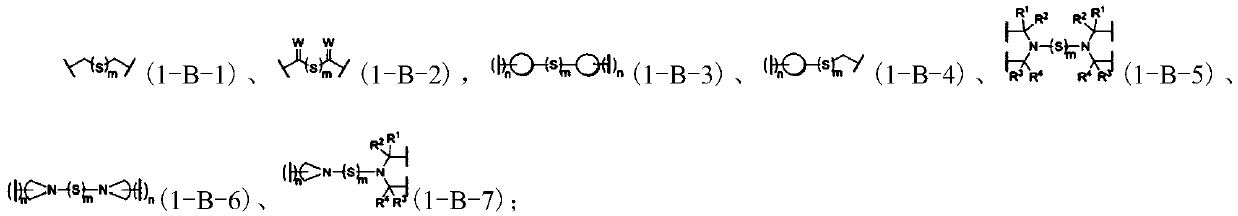

Method used

Image

Examples

Embodiment approach

[1740] In the present invention, the mechanoresponsive polymer may have one, two or more than two glass transition temperatures, or may not have a glass transition temperature. Among them, in a preferred embodiment of the present invention, at least one of the glass transition temperatures of the mechanoresponsive polymer is higher than 100°C, more preferably all of them are higher than 100°C, and the size of the resulting mechanoresponsive polymer Stability, mechanical strength, and high temperature resistance are good, and are suitable for application scenarios with high requirements for stress bearing and rigidity; in another preferred embodiment of the present invention, the glass transition temperature of the mechanoresponsive polymer is at least One of them is between 25 and 100°C, more preferably all of them are between 25 and 100°C, which is convenient for preparing polymer products in the form of ordinary solids, foams, and gels above room temperature, and is suitable ...

Embodiment 1

[1757]

[1758] Take 3 molar equivalents of carboxy-terminated four-armed polyethylene glycol (molecular weight is 2000), 15 molar equivalents of N-hydroxysuccinimide, and 15 molar equivalents of dicyclohexylcarbodiimide, place them in a reaction vessel, and add an appropriate amount of tetrahydrofuran Dissolve, under a nitrogen atmosphere, stir and react at room temperature for 12 hours, then add 3 moles of compound (a) and 3 moles of compound (b), continue stirring and reacting at room temperature for 24 hours, remove impurities and solvents after the reaction, and obtain cross-linked polymer and then swell 40g of the purified product in a large amount of purple litmus aqueous solution, and after reaching the swelling equilibrium, a polymer hydrogel can be obtained. The measured tensile strength of the gel was 1.68 MPa, and the elongation at break was 955%. When stretching the gel, as the stretching deformation increases, the gel will gradually turn red, and the gel will ...

Embodiment 2

[1760]

[1761] Take 0.5 molar equivalents of pendant carboxypolysiloxane (a), 10 moles of compound (b), 5 moles of compound (c), and 30 moles of compound (d), place them in a reaction vessel, and use an appropriate amount of Dissolved acetonitrile, then added 60 molar equivalents of dicyclohexylcarbodiimide and 20 molar equivalents of 4-dimethylaminopyridine, then stirred and reacted at room temperature for 36 hours, then placed the product in a mold, and placed it in a vacuum oven at 90°C After drying for 6 hours, and then slowly cooling down to room temperature, a polymer elastomer can be obtained. Under the action of mechanical force, the non-covalent mesosensitive group in the elastomer is activated by force, causing a change in fluorescence; and the triarylsulfide series mesosensitive group can generate phenyl cations after being activated by force, and combine with the side group The nucleophilic secondary amino group reacts to obtain cross-linking, which is benefici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com