Method for preparing lithium ion battery positive electrode material and precursor thereof through high-temperature and high-pressure steam pretreatment

A lithium-ion battery, high temperature and high pressure technology, applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as pollution, increase production costs, increase process complexity, etc., achieve simple production process, reduce particle size of raw materials , powder compaction and discharge capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put lithium carbonate, iron oxide, and ammonium dihydrogen phosphate in accordance with Li, Fe, PO 4 Add 1 mol each, and then add 0.02 mol glucose to dry and mix uniformly. After mixing, add zirconia media ball mill and mix for 3 hours. Then, use steam jet mill at 250°C and 1Mpa pressure to crush the precursor powder. The precursor powder is put into a box furnace under the protection of nitrogen, and the temperature is raised to 720°C at a rate of 15°C / min. After a constant temperature of 8 hours, it is naturally cooled to room temperature and taken out to obtain the cathode material LiFePO. 4 / C.

[0029] Take 50g cathode material LiFePO 4 / C powder, put it into the XL-185 powder compaction density tester, with a pressure of 3 tons, the material's split compaction density is 2.46g / cm 3 .

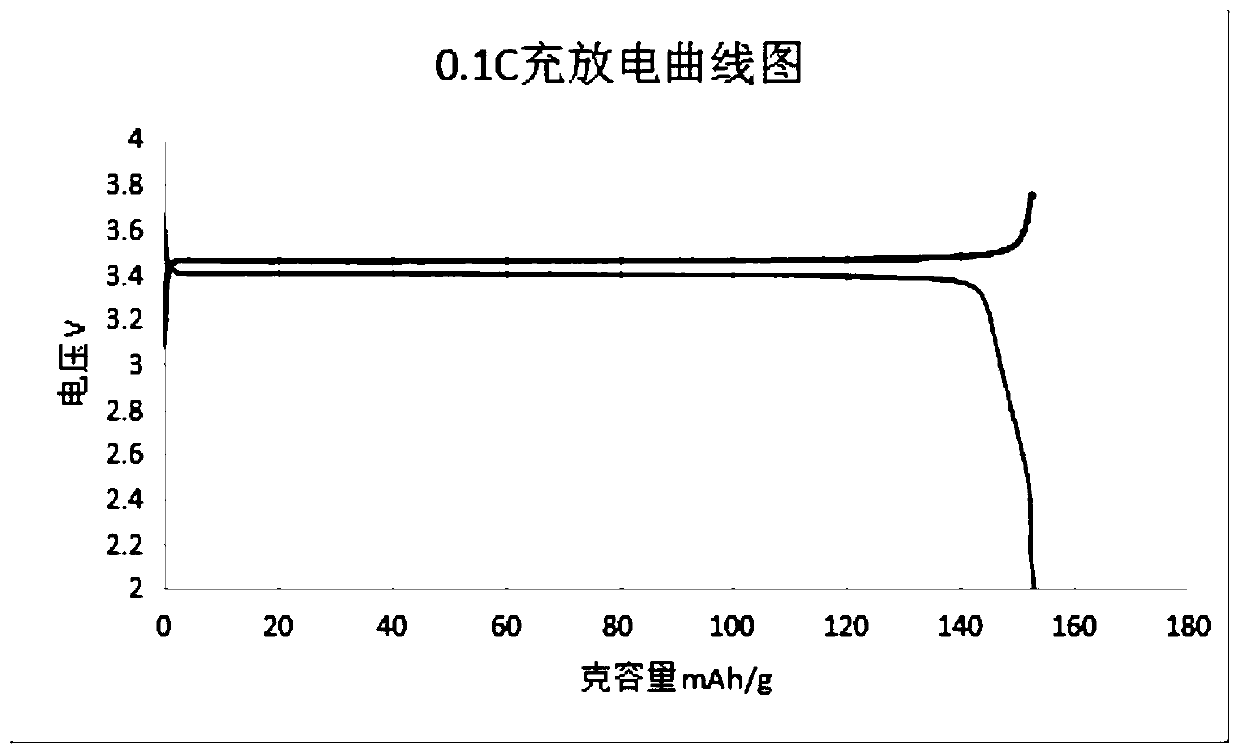

[0030] LiFePO 4 / C powder, acetylene black, and PVDF are mixed uniformly according to the mass ratio of 87:8:5, and then coated on 0.02mm aluminum foil, and then fully dried to obtain the...

Embodiment 2

[0032] Put lithium carbonate, iron oxide, ammonium dihydrogen phosphate according to Li, Fe, PO 4 Add 1 mol each, and then add 0.02 mol glucose to dry mix uniformly. After mixing, add zirconia media ball mill and mix for 3 hours. Then, use steam jet mill at 300℃ and 1Mpa pressure to crush the precursor powder. The precursor powder is put into a box furnace under the protection of nitrogen, and the temperature is raised to 720°C at a rate of 15°C / min. After a constant temperature of 8 hours, it is naturally cooled to room temperature and taken out to obtain the cathode material LiFePO 4 / C.

[0033] Take 50g cathode material LiFePO 4 / C powder, put it into the XL-185 powder compaction density tester, with a pressure of 3 tons, the material's split compaction density is 2.49g / cm 3 .

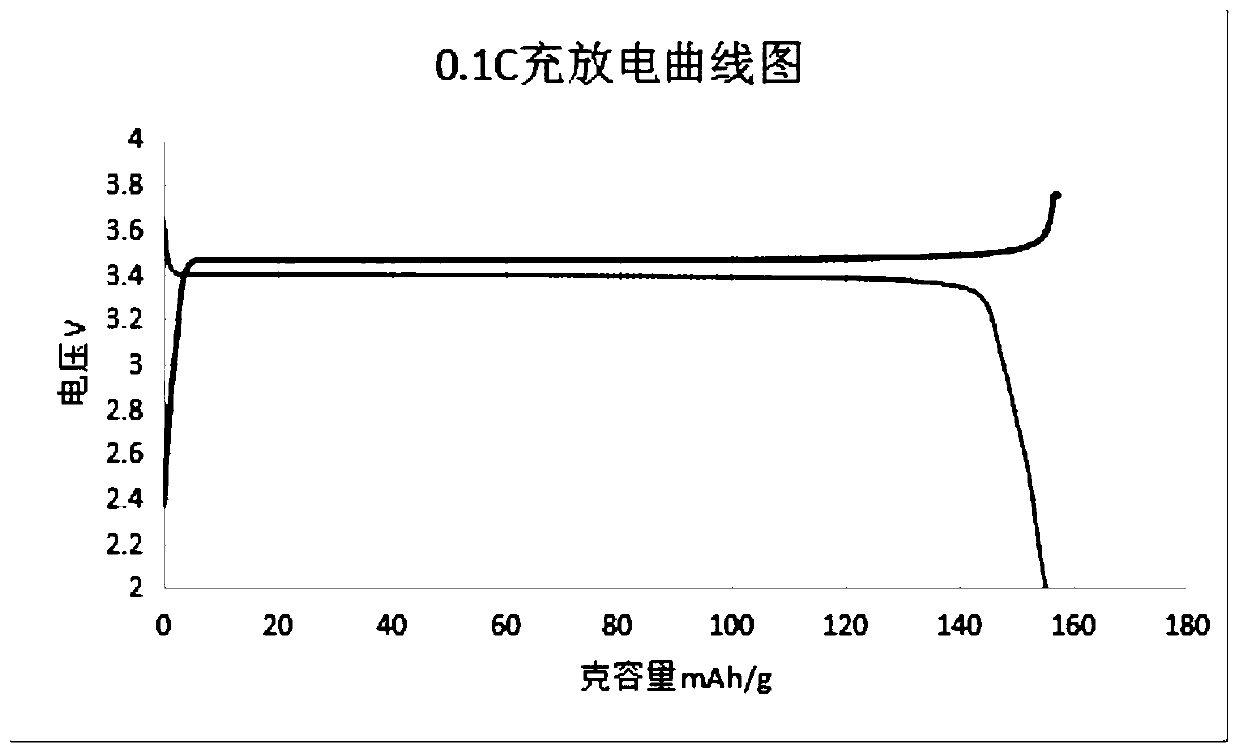

[0034] LiFePO 4 / C powder, acetylene black, and PVDF are mixed uniformly according to the mass ratio of 87:8:5, and then coated on 0.02mm aluminum foil, and then fully dried to obtain the positive pole p...

Embodiment 3

[0036] Put lithium carbonate, iron oxide, ammonium dihydrogen phosphate according to Li, Fe, PO 4 Add 1mol each, then add 0.02mol glucose, dry mix uniformly, add zirconia media ball mill and mix for 3h after mixing, and then crush in a steam jet mill at 250℃, 1.5Mpa steam pressure to obtain the precursor Powder, put the precursor powder into a box furnace under the protection of nitrogen, raise it to 720°C at 15°C / min, keep it at a constant temperature for 8 hours, then cool it to room temperature naturally and take it out to obtain the cathode material LiFePO 4 / C.

[0037] Take 50g cathode material LiFePO 4 / C powder, put it into the XL-185 powder compaction density tester, with a pressure of 3 tons, the material's split compaction density is 2.55g / cm 3 .

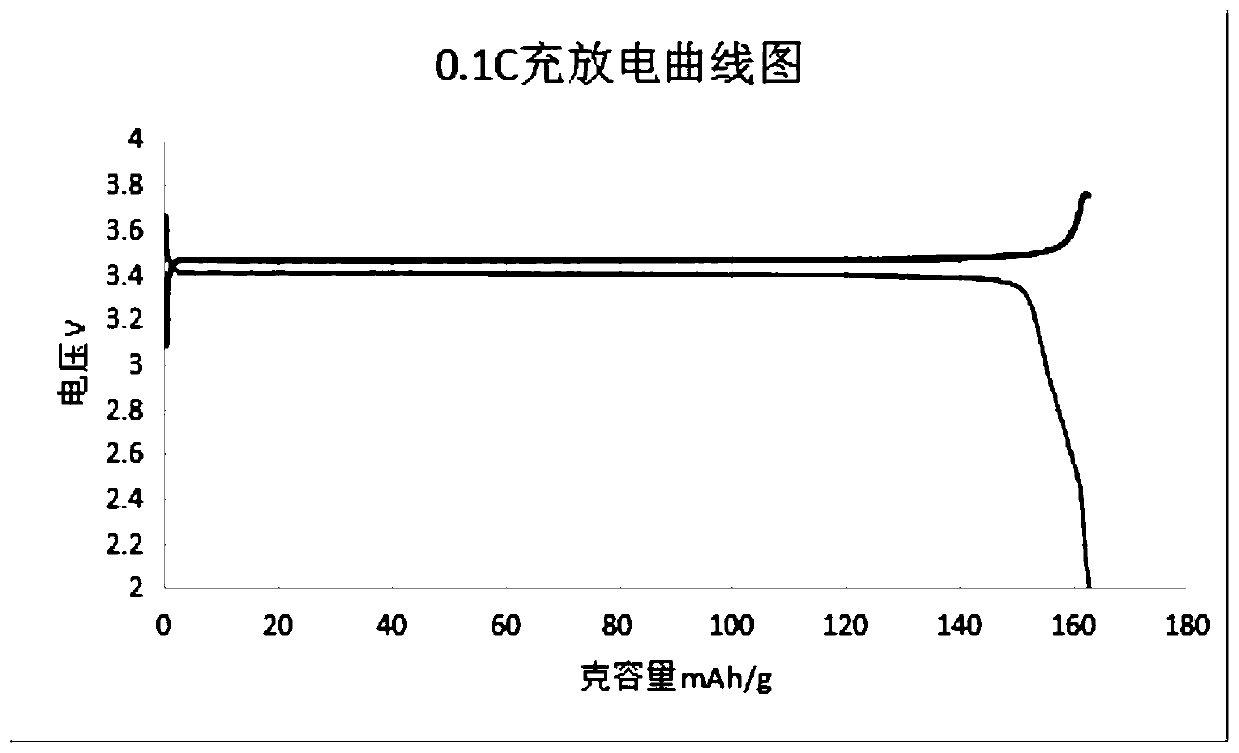

[0038] LiFePO 4 / C powder, acetylene black, and PVDF are mixed uniformly according to the mass ratio of 87:8:5, and then coated on 0.02mm aluminum foil, and then fully dried to obtain the positive pole piece, and then packed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com