Preparation method of TA32 titanium alloy powder for 3D printing

A 3D printing and titanium alloy technology, which is applied in the field of preparation of TA32 titanium alloy powder for 3D printing, can solve problems such as difficult titanium alloy powder, achieve excellent mechanical properties, improve fine powder yield, and solve the effect of long processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

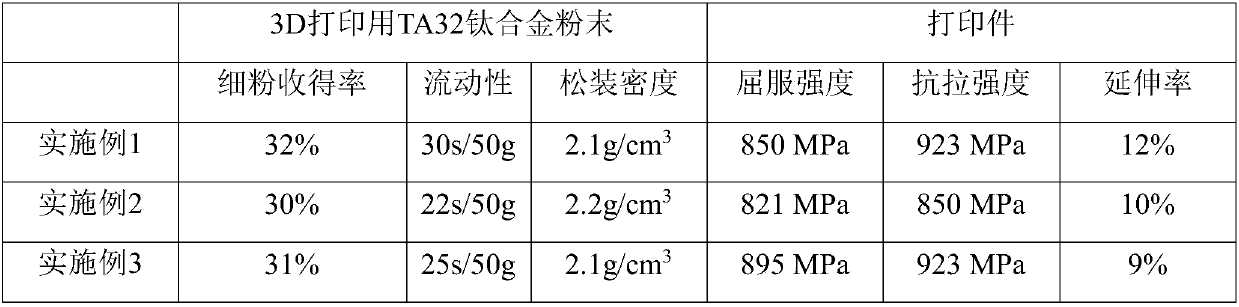

Embodiment 1

[0032] The invention provides a TA32 titanium alloy powder for 3D printing and a preparation method thereof. The preparation method is carried out according to the following steps:

[0033] Step 1: According to the following mass percentages: Al 5.0%, Zr 2.5%, Nb 0.2%, Mo 0.3%, Sn 3.0%, Ta 0.2%, Si 0.1%, and the balance is Ti and unavoidable impurities. Put the good raw materials in the copper crucible, then put the copper crucible into the induction melting equipment, increase the power of the equipment at a rate of 50KW / min, and when it reaches 390KW~400KW, maintain the power until the temperature of the titanium liquid in the copper crucible reaches 1750℃~1800℃, smelting for 5min~10min, and then flow into the mold through the nozzle to cool and solidify to form, so as to obtain TA32 titanium alloy ingot with a weight of 15kg~30kg;

[0034] Step 2: Use pickling solution to pickle the surface of the TA32 titanium alloy ingot to remove the surface reaction layer and prevent co...

Embodiment 2

[0041] The invention provides a TA32 titanium alloy powder for 3D printing and a preparation method thereof. The preparation method is carried out according to the following steps:

[0042] Step 1: According to the following mass percentages: Al 6.5%, Zr 4%, Nb 1.0%, Mo 2.0%, Sn 4.5%, Ta 0.8%, Si 0.6%, and the balance is Ti and unavoidable impurities. Put the raw materials in the copper crucible, then put the copper crucible into the induction melting equipment, increase the power of the equipment at a rate of 50KW / min, and when it reaches 390KW~400KW, maintain the power until the temperature of the titanium liquid in the copper crucible reaches 1750 ℃~1800℃, smelting for 5min~10min, and then flow into the mold through the nozzle to cool and solidify to form, so as to obtain TA32 titanium alloy ingot with a weight of 15kg~30kg;

[0043] Step 2: Use pickling solution to pickle the surface of the titanium alloy ingot to remove the surface reaction layer and prevent contamination...

Embodiment 3

[0050] The invention provides a TA32 titanium alloy powder for 3D printing and a preparation method thereof. The preparation method is carried out according to the following steps:

[0051] Step 1: According to the following mass percentages: Al 5.5%, Zr 3%, Nb 0.5%, Mo 0.6%, Sn 3.5%, Ta 0.5%, Si 0.4%, the balance is Ti and unavoidable impurities, and the prepared Put the raw materials in the copper crucible, then put the copper crucible into the induction melting equipment, increase the power of the equipment at a rate of 50KW / min, and when it reaches 390KW~400KW, maintain the power until the temperature of the titanium liquid in the copper crucible reaches 1750 ℃~1800℃, smelting for 5min~10min, and then flow into the mold through the nozzle to cool and solidify to form, so as to obtain TA32 titanium alloy ingot with a weight of 15kg~30kg;

[0052] Step 2: Use pickling solution to pickle the surface of the titanium alloy ingot to remove the surface reaction layer and prevent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com