Three-dimensional printing material as well as preparation method and application thereof

A technology of 3D printing and raw materials, which is applied in application, 3D printing, additive manufacturing, etc. It can solve the problems of poor shape and difficulty in restoring bone function, achieve good biocompatibility, promote cell proliferation and osteogenic differentiation, and achieve material properties Promoted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

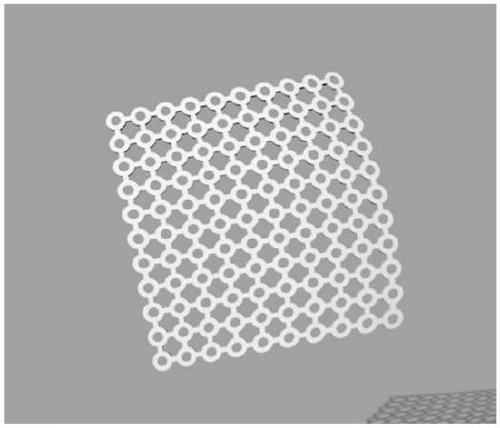

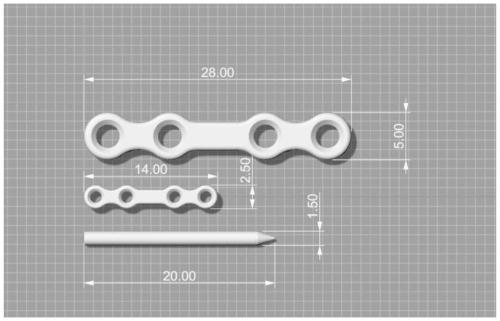

Image

Examples

Embodiment 1

[0039] 1 Materials and methods

[0040] 1.1 Main reagents

[0041]Polycaprolactone (polycaprolactone, PCL), polyetheretherketone (poly-ether-ether-ketone, PEEK), polylactic acid (polylactic acid, PLA), poly(lactic-co-glycolic acid copolymer) acid), PLGA), ethyl orthosilicate (TEOS), triethyl phosphate (TEP), hydroxyapatite (Hydroxyapatite, HA) (Mw=502.31g / mol, Mp=1100°C), surfactant P123 , concentrated nitric acid (HNO 3 ), calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O), chloral hydrate, and potassium oxalate were all purchased from Sinopharm Chemical Reagent Co., Ltd.; strontium chloride hexahydrate (SrCl 2 ·6H 2 O) was purchased from Merck; trypsin was purchased from Shanghai Pudong Biochemical Reagent Factory; α-MEM culture medium, fetal bovine serum, and PBS solution were purchased from Gibco; CCK-8 kit was purchased from Nanjing Novizan Biotechnology Co., Ltd.

[0042] 1.2 Main instruments

[0043] Ultra-clean bench (BCM-1000, Shanghai Hujing Medical Instrument...

Embodiment 2

[0120] Prepare 3D printing materials, the steps are as follows:

[0121] 1) Preparation of strontium-doped mesoporous bioactive glass (Sr-MBG): Dissolve 3.0g P123 in 120ml 2M nitric acid and 30ml deionized water, stir in a water bath at 37°C until a transparent solution is formed, and then pour into the solution Add 8.5gTEOS, 0.98g TEP, 5.35g Ca(NO 3 ) 2 4H 2 O and 0.67 g SrCl 2 ·6H 2 O, continue to stir in a water bath at 37°C for 12 hours, then transfer the solution to a hydrothermal kettle, perform hydrothermal treatment at 100°C for 48 hours, then transfer the solution to an oil bath at 100°C, and dry to obtain a powder. Finally, it is placed in a sintering furnace and sintered at 650°C to completely remove the surfactant;

[0122] 2) Polycaprolactone is broken into 3mm round particles through a grinder;

[0123] 3) Hydroxyapatite, polylactic acid, polyetheretherketone and the prepared strontium-doped mesoporous bioactive glass are all prepared into nanoparticles (<2...

Embodiment 3

[0126] Prepare 3D printing materials, the steps are as follows:

[0127] 1) Preparation of strontium-doped mesoporous bioactive glass (Sr-MBG): Dissolve 3.0g P123 in 120ml 2M nitric acid and 30ml deionized water, stir in a water bath at 37°C until a transparent solution is formed, and then pour into the solution Add 8.5gTEOS, 0.98g TEP, 5.35g Ca(NO 3 ) 2 4H 2 O and 0.67 g SrCl 2 ·6H 2 O, continue to stir in a water bath at 37°C for 12 hours, then transfer the solution to a hydrothermal kettle, perform hydrothermal treatment at 100°C for 48 hours, then transfer the solution to an oil bath at 100°C, and dry to obtain a powder. Finally, it is placed in a sintering furnace and sintered at 650°C to completely remove the surfactant;

[0128] 2) Polycaprolactone is broken into 3mm round particles through a grinder;

[0129] 3) Hydroxyapatite, polylactic acid, polyetheretherketone and the prepared strontium-doped mesoporous bioactive glass are all prepared into nanoparticles (<2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com