Method for preparing coal gangue magnetic adsorbent by two-step method

A magnetic adsorbent, coal gangue technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, magnetic field/electric field water/sewage treatment, etc. problems, to achieve the effect of saving iron salt raw materials, simplifying the preparation process, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

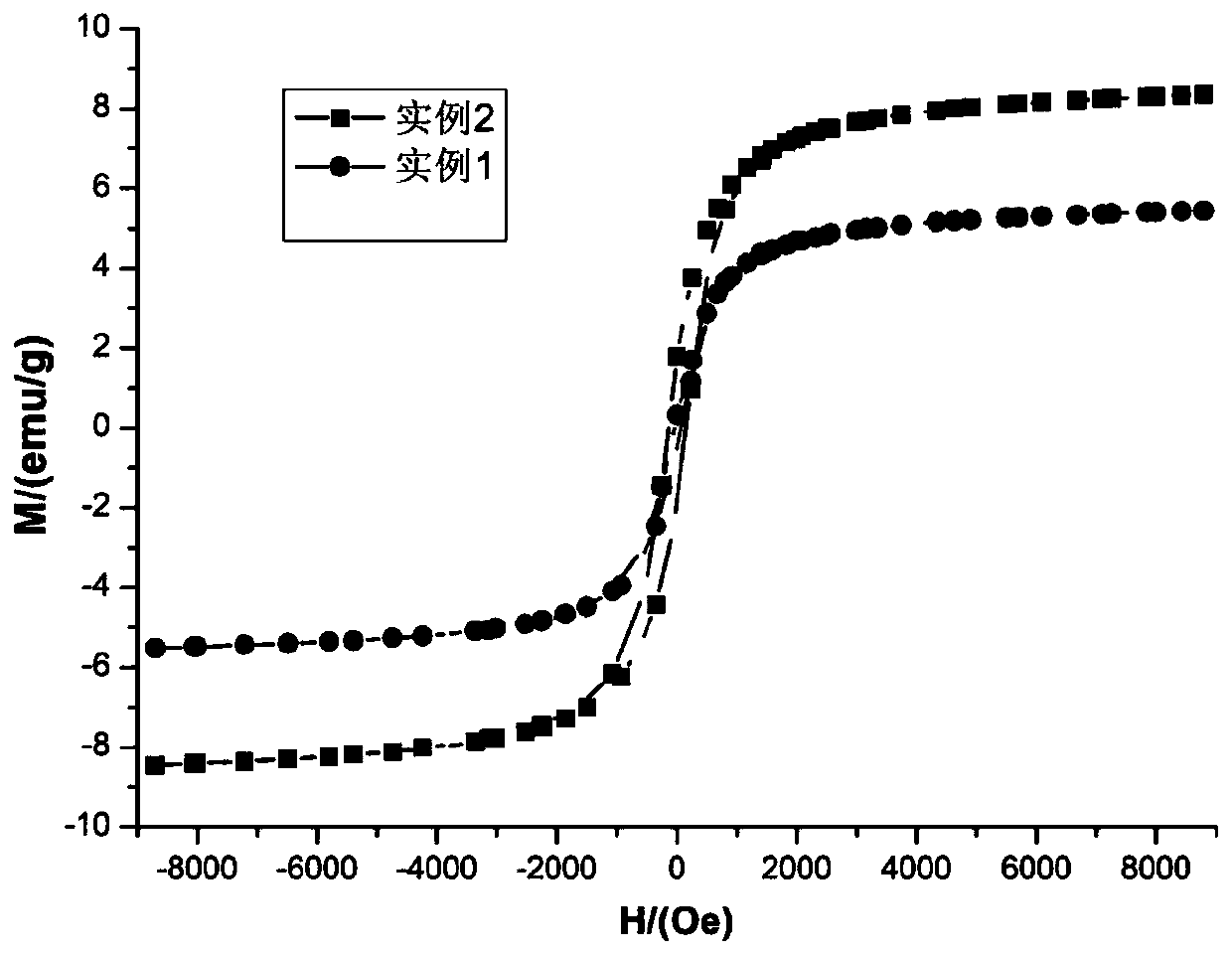

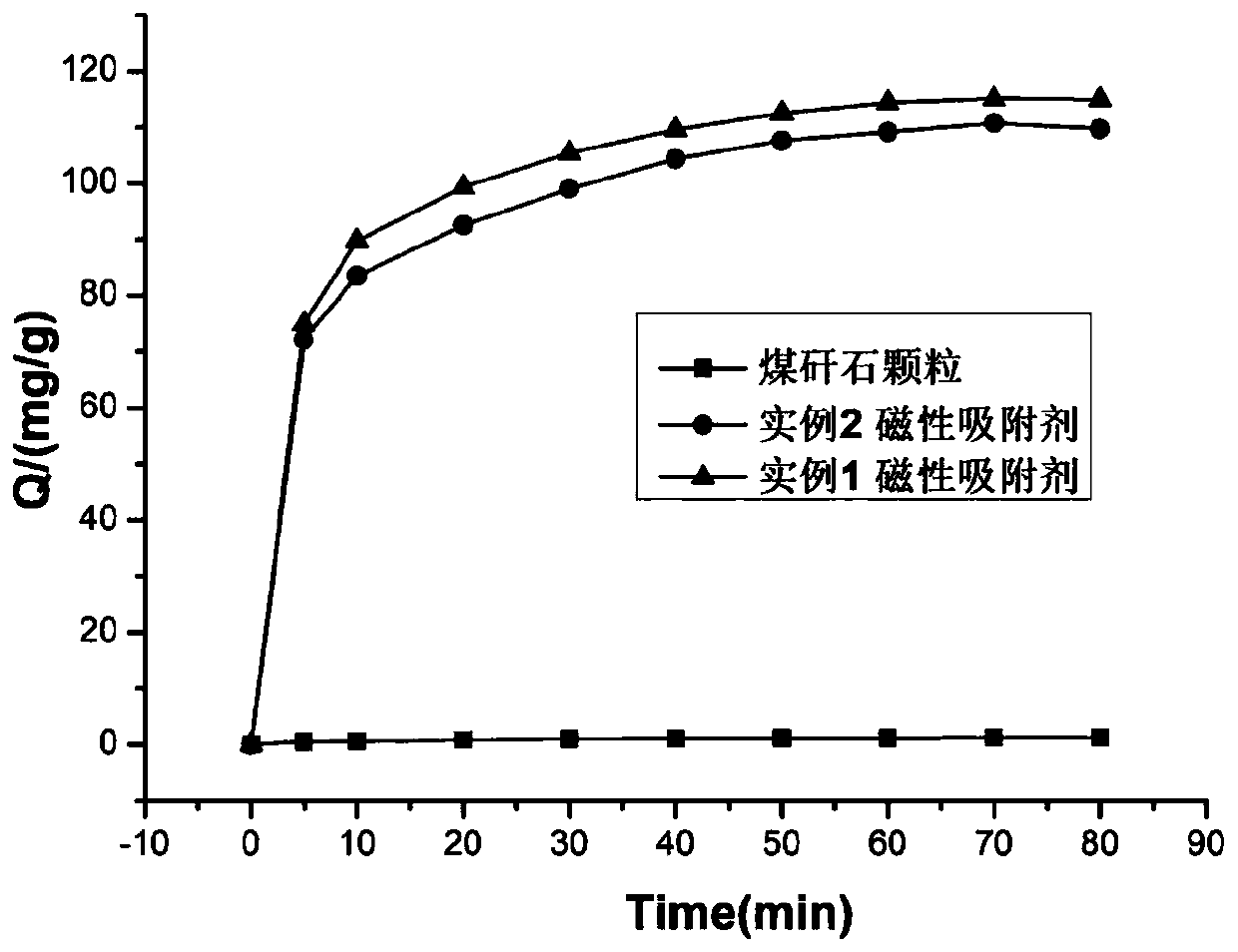

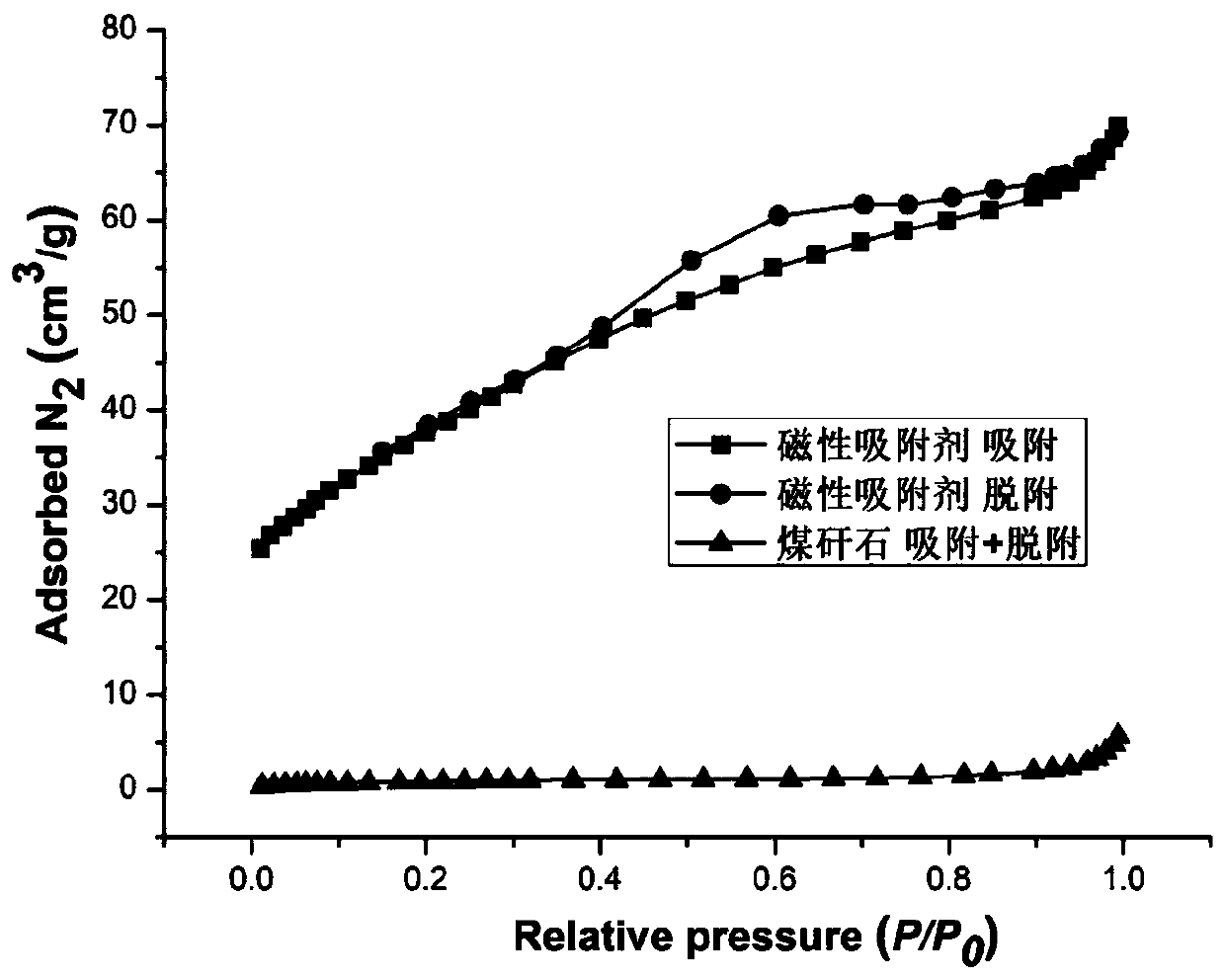

Embodiment 1

[0026] Coal gangue from the Lianghuai area of Anhui Province was used as the raw material for the preparation of the magnetic adsorbent, and the dry basis volatile content of the coal gangue was 7.91%; mineral composition (mass fraction): SiO 2 61.14%, Al 2 o 3 27.47%, other ingredients 11.39%. Magnetic adsorbent preparation process:

[0027] (1) Coal gangue pretreatment: coarsely crush the coal gangue with a jaw crusher and grind with a ball mill to obtain fine coal gangue particles, and use a vibrating sieve to obtain coal gangue particles with a particle size of 200-325 mesh.

[0028] (2) The coal gangue particles obtained by pretreatment were mixed with 12.1g coal gangue and 1.61g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Mix well, add water and stir for 10 minutes, then place in a blast oven at 120° C. and dry for 6 hours to obtain a mixture.

[0029] (3) Put the mixed material in a closed electric resistance furnace, rapidly raise the temperature to 450°C, ...

Embodiment 2

[0034] Coal gangue from the Lianghuai area of Anhui Province is used as the raw material for the preparation of the magnetic adsorbent, and the volatile content of the dry basis of coal gangue is 11.28%; mineral composition (mass fraction): SiO 2 55.82%, Al 2 o 3 25.15%, other ingredients 19.03%. Magnetic adsorbent preparation process:

[0035] (1) Coal gangue pretreatment: coarsely crush the coal gangue with a jaw crusher and grind with a ball mill to obtain fine coal gangue particles, and use a vibrating sieve to obtain coal gangue particles with a particle size of 200-325 mesh.

[0036] (2) The coal gangue particles obtained by pretreatment were mixed with 12.1g coal gangue and 2.42g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Mix well, add water and stir for 10 minutes, then place in a blast oven at 120° C. and dry for 6 hours to obtain a mixture.

[0037] (3) Place the mixture in a closed electric resistance furnace, rapidly heat up to 450°C, and keep warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com