Preparation method of waterproof suit fabric

A technology for fabrics and suits, which is applied in the field of preparation of waterproof suit fabrics, can solve the problems of destroying the molecular structure of water-based polyurethane, affecting the performance of the coating, and decreasing the mechanical strength, and achieves the effects of easy control, improved waterproofness and less side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

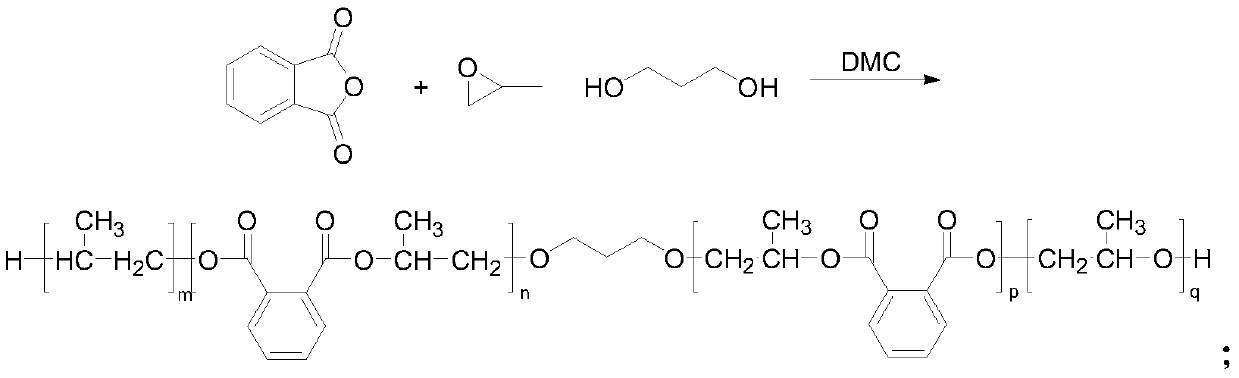

[0040] Preparation of polyether diols:

[0041] Add 50g of phthalic anhydride, 25g of 1,3-propanediol and 1g of DMC catalyst into the reaction flask, raise the temperature to 100°C for dehydration under reduced pressure for 0.5h, then replace with nitrogen for 3 times, then add 30g of propylene oxide after raising the temperature to 120°C , reacted for 6h, and removed small molecular impurities under reduced pressure to obtain polyether diol.

Embodiment 2

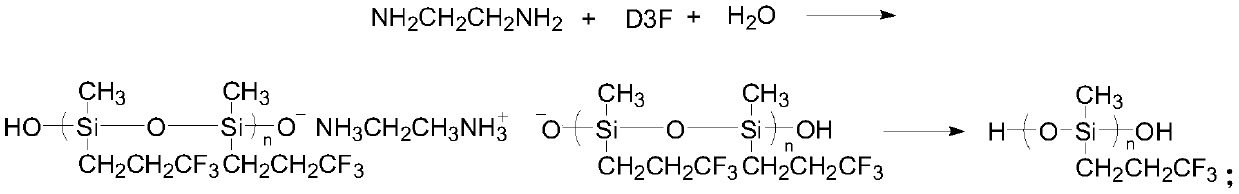

[0043] Preparation of fluorine-containing silicone oil:

[0044] Under nitrogen protection, add 1g of ethylenediamine and 0.5g of deionized water into the reaction flask, heat to 50-60°C and stir for 0.5h, then add 100g of trifluoropropylmethylcyclotrisiloxane (D3F) and heat up to 110°C, react for 6 hours, and remove water and ethylenediamine under reduced pressure to obtain fluorine-containing silicone oil.

Embodiment 3

[0046] Preparation of modified polyurethane emulsion:

[0047] A1. Under the protection of nitrogen, add 50g of polyether diol into the reaction flask, heat to 60°C, and add 80g of isophorone diisocyanate dropwise, then raise the temperature to 90°C, and keep it warm for 2 hours to obtain Polymer 1;

[0048] A2. Under nitrogen protection, add 5g of dimethylolpropionic acid, 5g of 1,4-butanediol and 1g of stannous octoate to Polymer 1, raise the temperature to 75°C, and keep warm for 5 hours to obtain Polymer 2;

[0049] A3. Under the protection of nitrogen, the temperature of Polymer 2 was lowered to 60°C, and 15g of fluorine-containing silicone oil was added to the reaction bottle, reacted for 3 hours, and then 10g of acetone was added to obtain Polymer 3;

[0050] A4. Under the protection of nitrogen, lower the temperature of Polymer 3 to 35°C, add 5g of triethylamine, stir for 0.5h, then dropwise add 200g of deionized water, and continue stirring for 2h to obtain modified p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com