A kind of composite solder containing WC and ZRC at the same time, its preparation method, and the method for brazing

A composite brazing material and brazing technology, which is applied in the direction of welding equipment, manufacturing tools, welding media, etc., can solve the problems of uneven distribution, agglomeration, wettability and climbing height difference of the brazing material, and improve the brazing material Effects of wettability and climbing height, improvement of bonding strength, and improvement of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

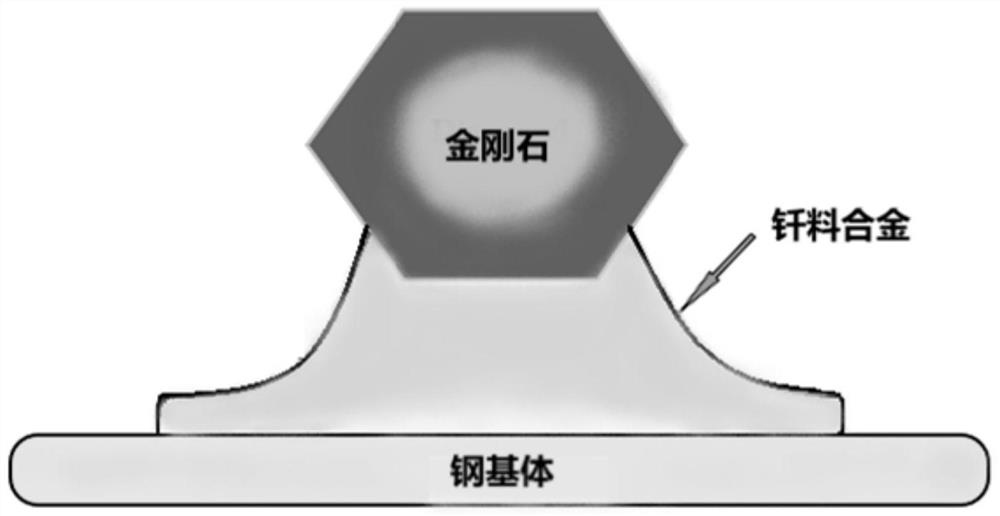

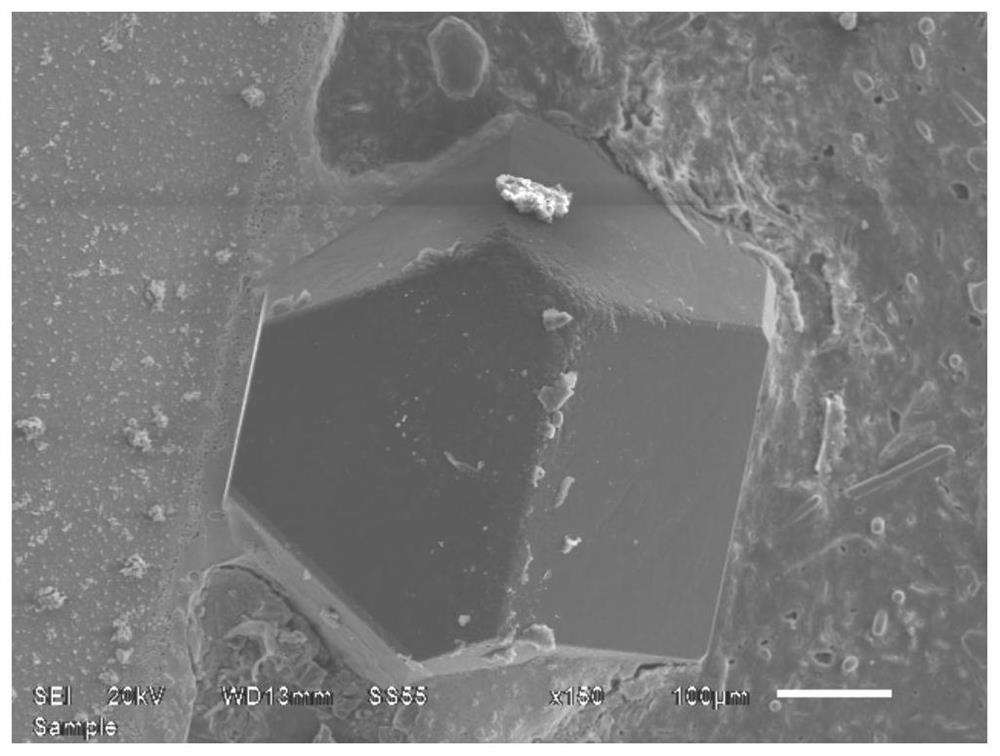

[0050] A composite solder containing both WC and ZrC in this embodiment includes CuSnTi alloy phase and WC, ZrC mixed reinforcement phase, wherein the CuSnTi alloy phase includes 70% Cu, 20% Sn and 10% Ti, WC The addition amount of powder is 10% of the volume percentage of CuSnTi alloy phase, the particle size of WC powder is 50 μm, the addition amount of ZrC powder is 5% of the volume percentage of CuSnTi alloy phase, and the particle size of ZrC powder is 1 μm.

[0051] The composite solder containing WC and ZrC in this embodiment is used to connect diamond and Q460 steel to make a diamond grinding tool by brazing. Specifically, the preparation method of the composite solder in this embodiment and its implementation The steps of the brazing method are:

[0052] (1) According to the mass percentage, 70% Cu powder, 20% Sn powder and 10% Ti powder are uniformly mixed to obtain the CuSnTi alloy phase;

[0053] (2) After adding WC powder accounting for 10% by volume of the CuSnT...

Embodiment 2

[0059] A composite solder containing both WC and ZrC in this embodiment includes CuSnTi alloy phase and WC, ZrC mixed reinforcement phase, wherein the CuSnTi alloy phase includes 70% Cu, 20% Sn and 10% Ti, WC The addition amount of powder is 3.5% of the volume percentage of CuSnTi alloy phase, the particle size of WC powder is 40 μm, the addition amount of ZrC powder is 1.5% of the volume percentage of CuSnTi alloy phase, and the particle size of ZrC powder is 2 μm.

[0060] The composite solder containing WC and ZrC in this embodiment is used to connect diamond and Q460 steel to make a diamond grinding tool by brazing. Specifically, the preparation method of the composite solder in this embodiment and its implementation The steps of the brazing method are:

[0061] (1) According to the mass percentage, 70% Cu powder, 20% Sn powder and 10% Ti powder are uniformly mixed to obtain the CuSnTi alloy phase;

[0062] (2) After adding WC powder accounting for 3.5% of CuSnTi alloy ph...

Embodiment 3

[0068] A composite solder containing both WC and ZrC in this embodiment includes CuSnTi alloy phase and WC, ZrC mixed reinforcement phase, wherein the CuSnTi alloy phase includes 70% Cu, 20% Sn and 10% Ti, WC The amount of powder added is 8% of the volume percentage of CuSnTi alloy phase, the particle size of WC powder is 45 μm, the amount of ZrC powder added is 2% of the volume percentage of CuSnTi alloy phase, and the particle size of ZrC powder is 3 μm.

[0069] The composite solder containing WC and ZrC in this embodiment is used to connect diamond and Q460 steel to make a diamond grinding tool by brazing. Specifically, the preparation method of the composite solder in this embodiment and its implementation The steps of the brazing method are:

[0070] (1) According to the mass percentage, 70% Cu powder, 20% Sn powder and 10% Ti powder are uniformly mixed to obtain the CuSnTi alloy phase;

[0071] (2) After adding WC powder accounting for 8% volume percentage of CuSnTi al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com