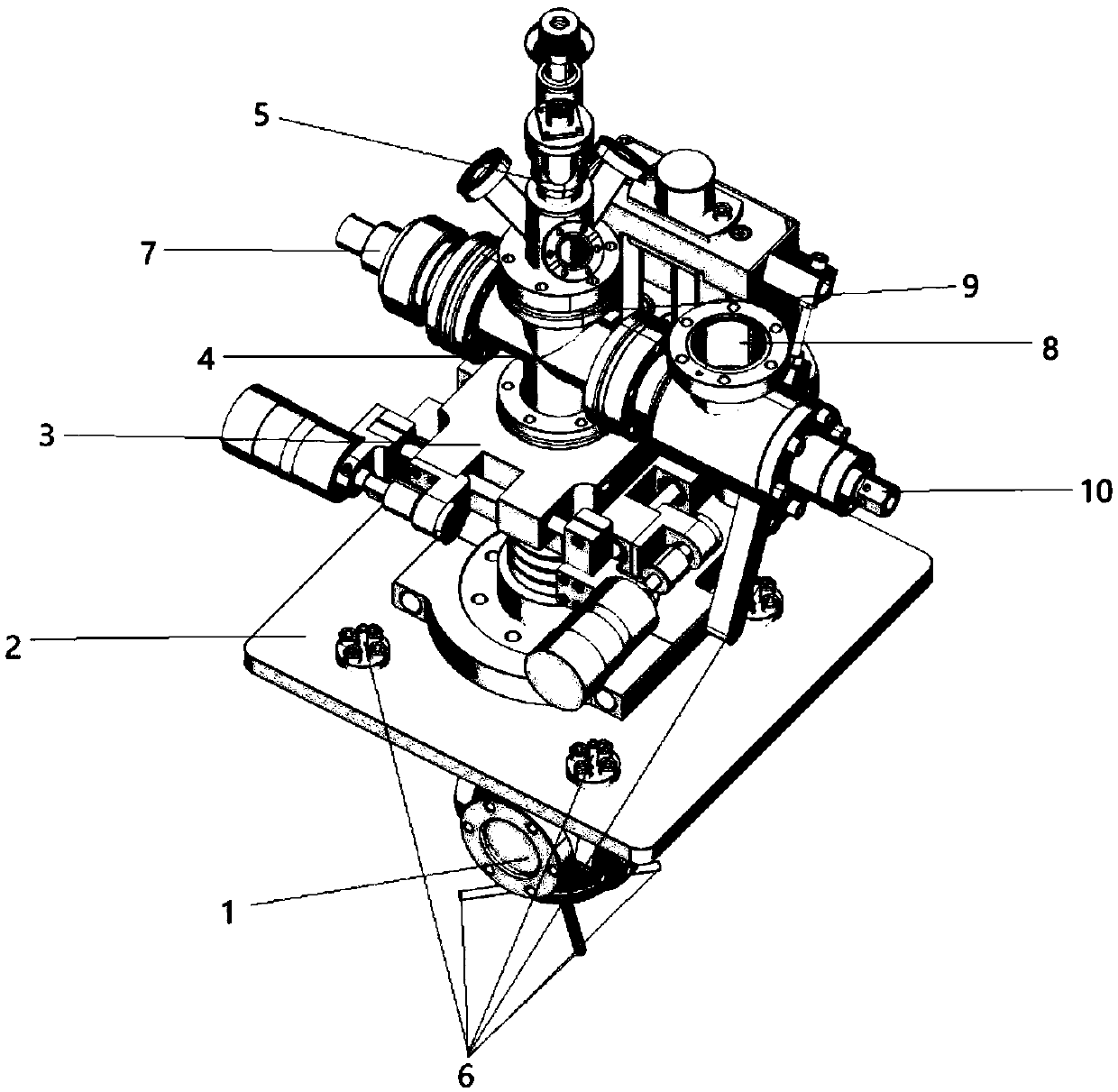

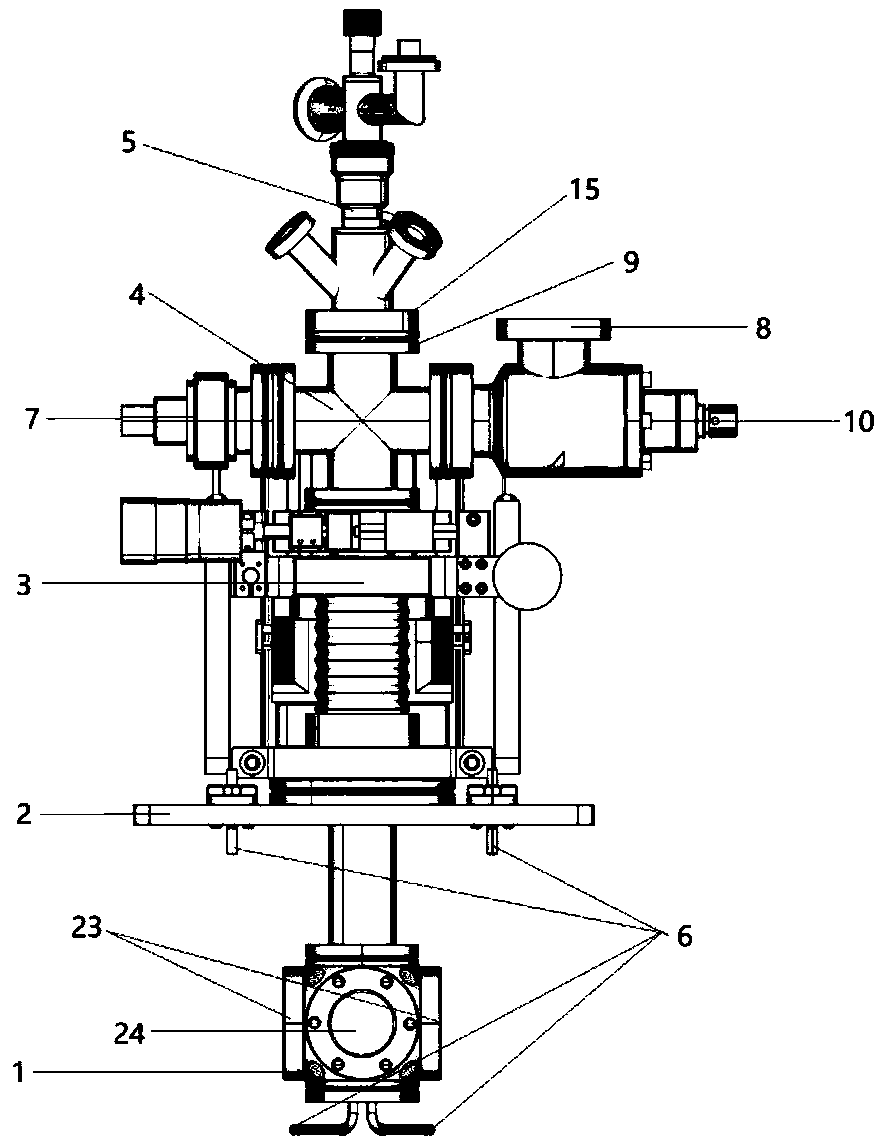

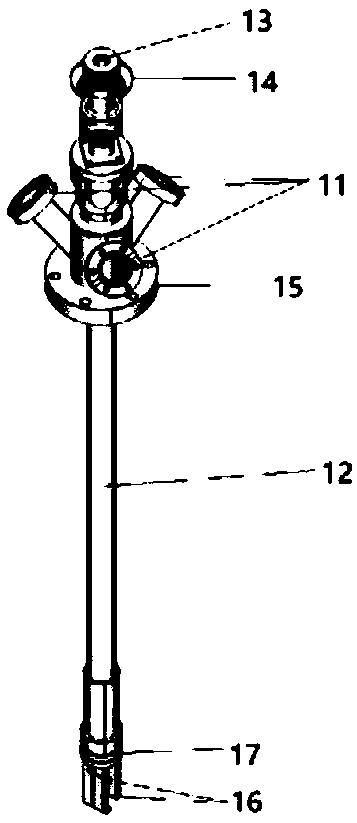

Temperature-controllable infrared in-situ reaction tank based on high vacuum condition from low temperature to high temperature

An in-situ reaction, infrared technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problem that infrared cells are difficult to achieve high vacuum and low temperature, difficult in-situ high temperature treatment of samples, and low melting point of potassium bromide. and other problems to achieve the effect of preventing corrosion, reducing dosage and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Low temperature CO adsorption test of ZnO powder. First take a few milligrams of ZnO powder and press it on the center of a 2cm*1cm tungsten mesh. Install the tungsten mesh sample on the sample holder, and weld the thermocouple near the zinc oxide sample. Place the cold head on the three-dimensional translation stage, and rotate it to a suitable position so that the sample plane is perpendicular to the optical path, and seal and fix it with a copper gasket. Connect an external power supply and a K-type thermocouple thermometer. Turn on the molecular pump unit to evacuate the system, and add liquid nitrogen to the cold head cold trap when the vacuum drops to a certain level. After the sample is degassed through the external power supply parameters, the background is collected after returning to the liquid nitrogen temperature. Use leak valve to feed 10 -3 After mbarCO, the spectrum was collected, and the CO adsorption peak was obtained as shown in the figure. After ...

Embodiment 2

[0059] SiO 2 The supported PtFe catalyst is pressed on the tungsten grid and loaded. After installation, vacuum the system to the proper pressure. Close the suction angle valve and let H 2 And turn on the heating power to carry out activation pretreatment on the sample. After the treatment, the angle valve was opened to evacuate the system, and the temperature was naturally cooled to room temperature, and the background was collected under vacuum. Use a leak valve to feed 10 mbar CO to saturation, then evacuate and collect spectra to obtain the infrared signal of CO adsorbed on the surface. At this time, use the leakage valve to feed and maintain 5*10 -4 mbar oxygen, continuous spectrum collection can get the weakening of the surface CO infrared signal, and thus obtain the CO reaction rate on the surface of the PtFe catalyst, see Figure 6 .

Embodiment 3

[0061] Vapor deposition of CeO on silicon wafers 2 The thin film sample is coated with water and mounted on the sample holder. After installing the cold head, in N 2 The spectrum was collected under atmospheric pressure. After turning on the molecular pump group, pump the cavity to a vacuum of 10 -6 mbar, get spectrum again to get H 2 O in CeO 2 of chemical adsorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com