Silicon-based anion exchange resin and preparation method thereof

A technology of exchange resin and anion, applied to the material of anion exchanger, by removing certain components, weighing, instruments, etc., it can solve the problems of poor resin mechanical properties, large column pressure, slow kinetics, etc., and reduce the time. , The effect of low column pressure and high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

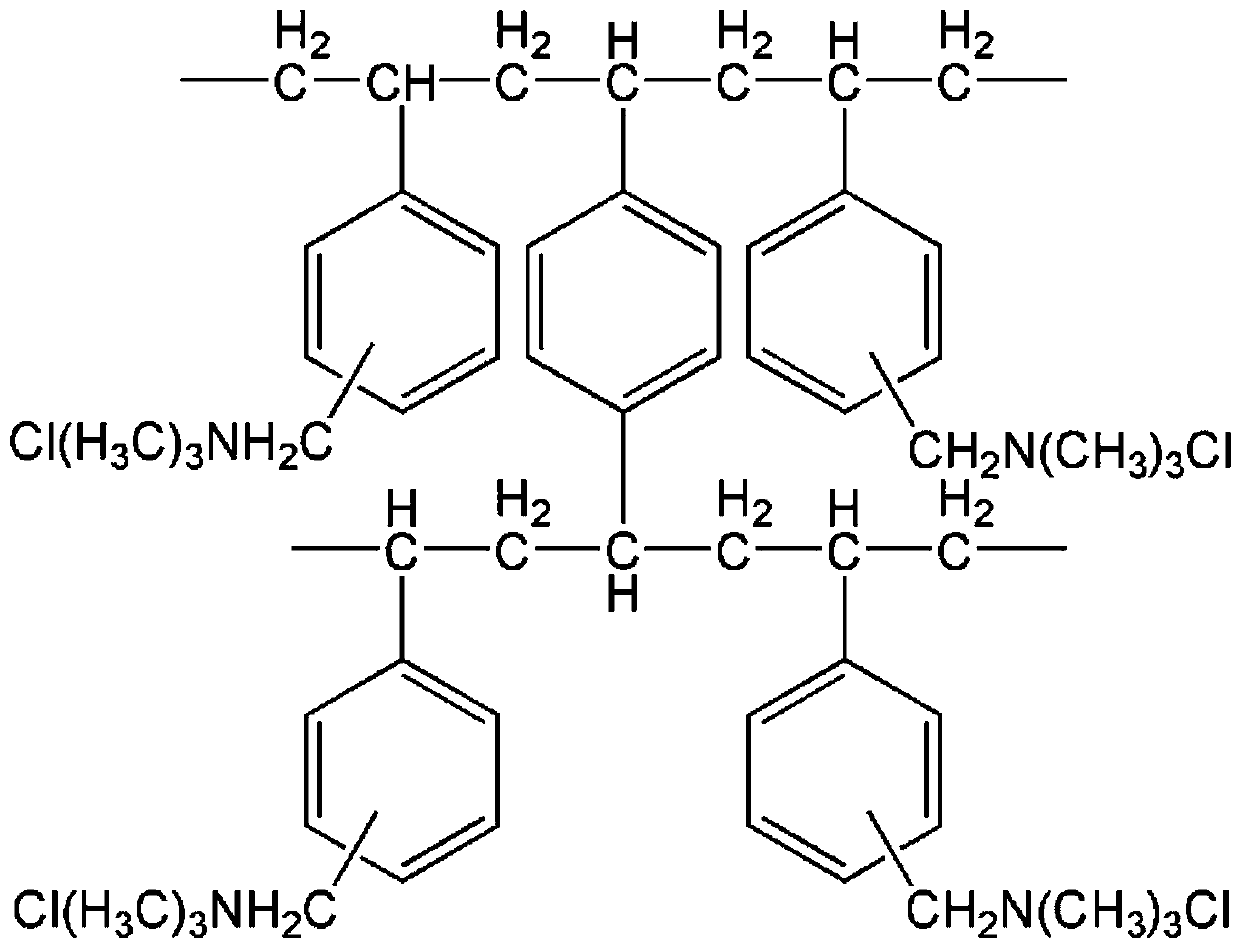

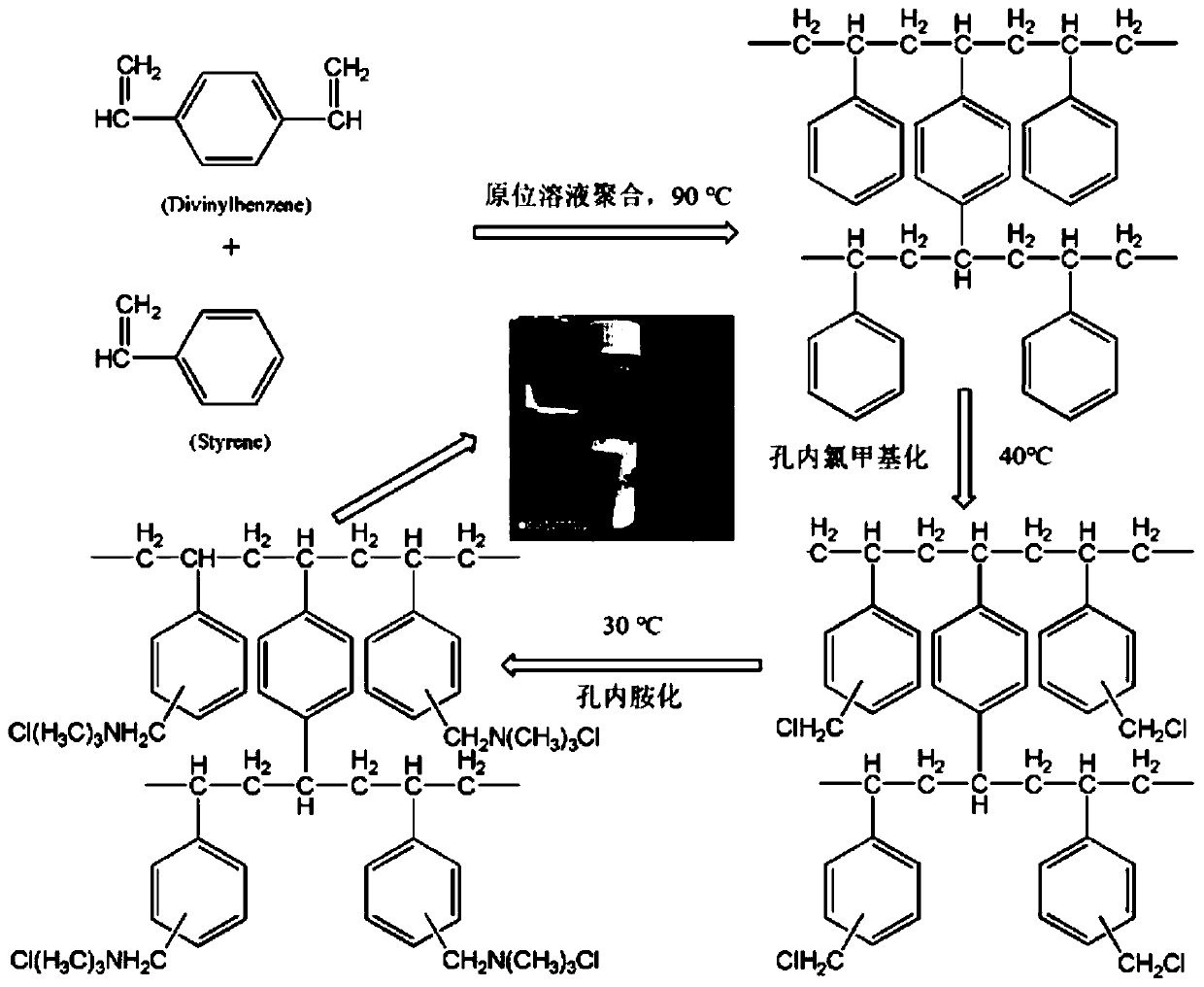

Method used

Image

Examples

Embodiment 1

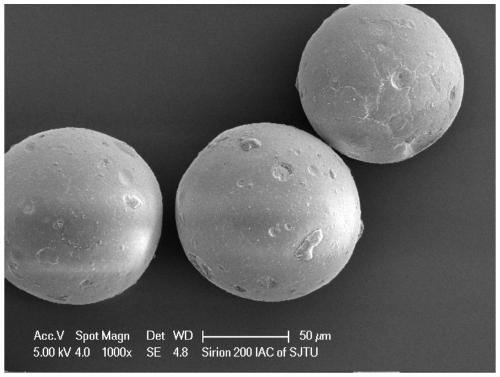

[0044] (1) Preparation of silicon-based white balls

[0045] Weigh 100g of a silica matrix with a porosity of 69% and a particle size of 75-150μm and transfer it to a rotary evaporator, and adjust the rotary evaporator to slow rotation so that the silica matrix is continuously stirred in the evaporating flask; Vacuum to 1kPa, repeat 2 to 3 times to exhaust the air in the pores of the silica matrix;

[0046] Take another beaker, add 44.68mL of diluent acetophenone and 29.78mL of diethyl titanate, after stirring, add 18.22ml of monomeric styrene and 6.36ml of divinylbenzene, continue to stir evenly, and then weigh the initiator Add 0.3191g of azobisisobutyronitrile and 0.2127g of 1,1'-azo (cyanocyclohexane) to the oil phase, stir until completely dissolved; maintain the vacuum in the rotary evaporator, from the feed liquid inlet The oil phase is sucked into the rotary evaporator by suction; speed up the rotation speed so that the oil phase is in full contact with the silica matrix...

Embodiment 2

[0060] Using the silicon-based anion exchange resin prepared in Example 1, the lead-210 analysis was performed on the water samples at Jiaoguchong and the main outlet of a mine in Fangchenggang City. The specific methods are as follows:

[0061] (1) Measure 2.5L of static water sample acidified to pH=2 with hydrochloric acid in a beaker of corresponding volume, add 9.75mg of stable lead carrier with 0.1mol / L nitric acid solution as the medium, and add mass while stirring Potassium permanganate solution with a concentration of 2g / 100mL, until the water sample shows a stable purple, let it stand for 30 minutes;

[0062] (2) Add 2.5mL Fe 3+ A ferric chloride solution with a concentration of 20mg / mL and a 1mol / L hydrochloric acid solution as the medium, keep stirring until the solution is uniform;

[0063] (3) Put the solution on a hot plate and heat it to 60℃ and then remove it. While stirring, slowly add 25%-28% ammonia water until pH=8.5~9.2, and stir once every half an hour until No...

Embodiment 3

[0073] The resin material 201×7 was used to analyze the lead-210 of the water samples at the foot-guchong and the main outlet of a mine in Fangchenggang City as described in Example 2. The analysis method was based on industry standards. The calculation method is the same as in Example 2. The results are shown in Table 1.

[0074] Table 1 Lead-210 test results of Examples 2 and 3

[0075]

[0076]

[0077] From Table 1, it can be seen that 201×7 and SiPS-N (CH 3 ) 3 The chemical recovery rate of Cl to lead-210 in water samples is higher than 95%. The activity concentrations of lead-210 in the water samples of Jiaoguchong and total discharge based on industry standards were 5.8mBq / L and 27.7mBq / L, respectively. However, the lead-210 activity concentrations of the resin of Example 1 and the process of Example 2 were 5.65 mBq / L and 22.3 mBq / L, which were lower than the industry standard measurement results. This shows that the resin and supporting processes used in this patent have...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Exchange capacity | aaaaa | aaaaa |

| Exchange capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com