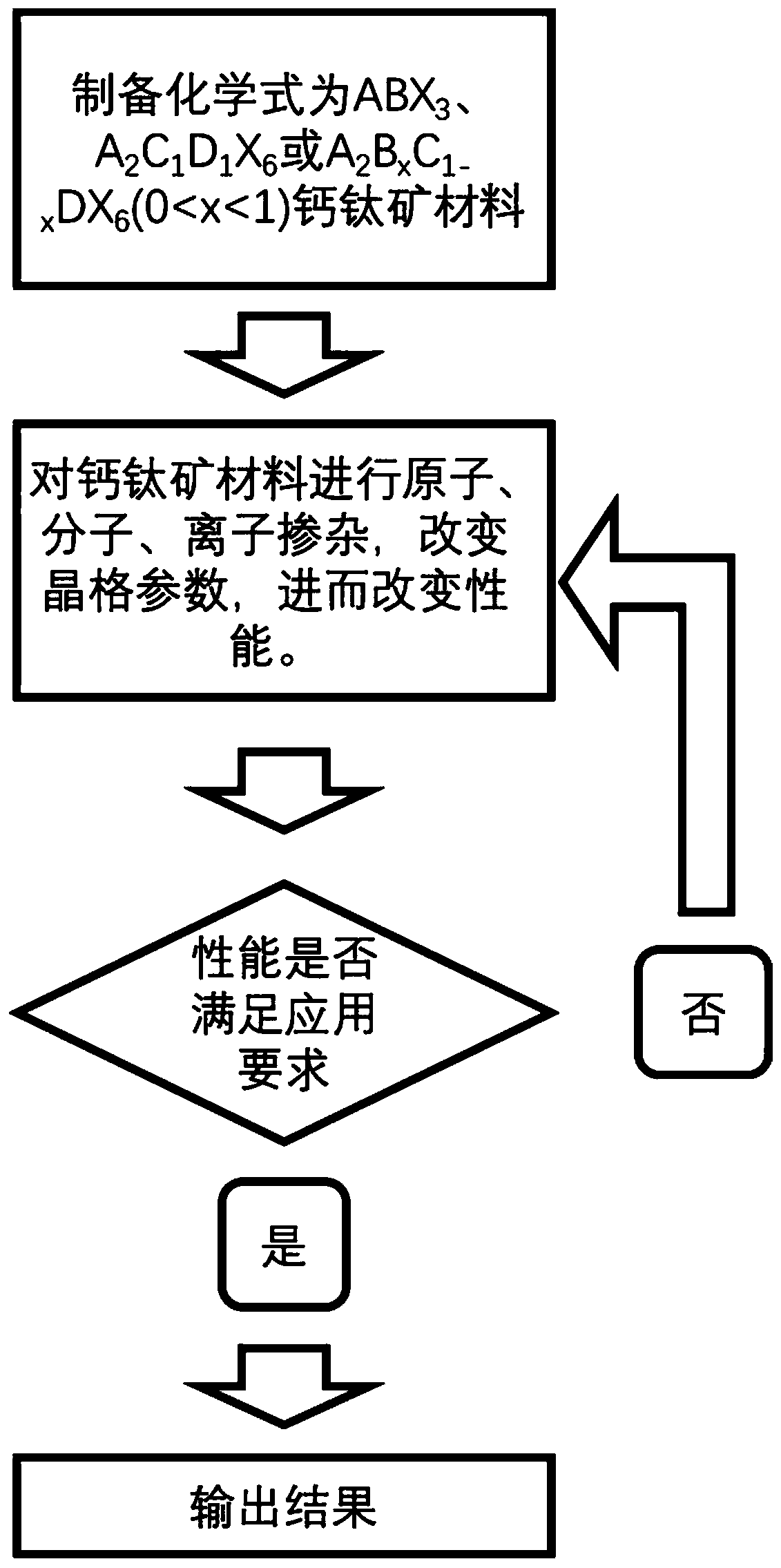

Method for improving perovskite performance by changing perovskite unit cell parameters

A unit cell parameter and perovskite technology, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve problems such as easy decomposition, poor stability, and limit the application of perovskite films, so as to improve performance, Excellent quality, effect of improving energy band structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

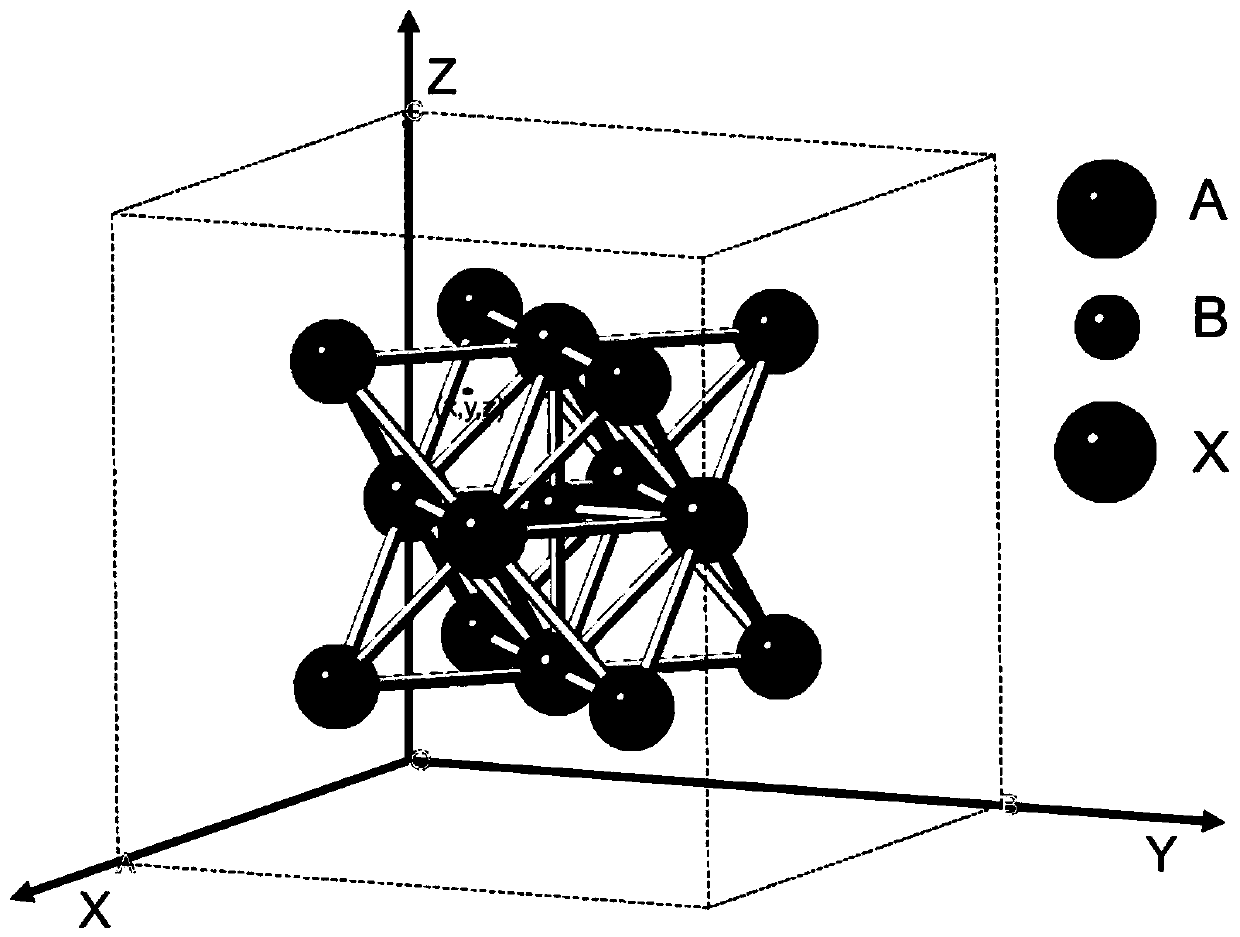

[0034] As an embodiment of the present invention, preferably, the perovskite material includes a structure of ABX 3 、A 2 C 1 D. 1 x 6 or A 2 B x C 1-x DX 6 (03 ,MASnI 3 ,FAPbI 3 ,CsSnI 3 ,MASnBr 3 ,CsSnCl 2 ,Cs 2 SnI 6 ,Cs 2 SnBr 6 ,MAGeI 3 ,CsGeI 3 ,CsGeBr 3 ,CsGeBr 3 ,CsGe 0.5 sn 0.5 I 3 ,CaTiO 3, SrTiO 3 , Cs 2 AgBr 6 ,Cs 2 AgBiCl 6 , Cs 2 AgInBr 6 , Cs 2 AgInCl 6 , Ba 2 Bi x Sb 1-x VO 6 One or more of (0

[0035] As an embodiment of the present invention, the specified gas experiment environment preferably includes one or more of nitrogen, argon, dry hot air, and helium.

[0036] As an embodiment of the present invention, when the perovskite material is doped with atoms, ions, or molecules, preferably, the doping ionization means include impact ionization, photoionization, thermal ionization, plasma, electrolysis, One or several chemical ionization methods.

[0037] As an embodiment of the present invention, when the p...

Embodiment 1

[0039] Embodiment 1: Based on light atom doping and ultra-thin perovskite film preparation method, it is used to prepare high-performance ultra-thin perovskite film.

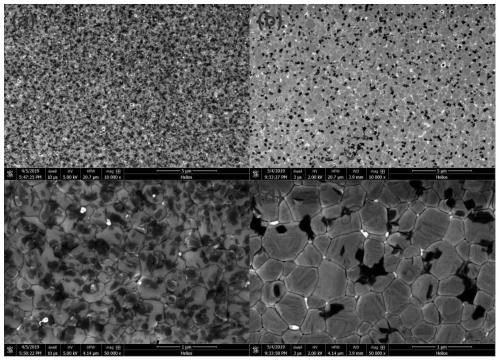

[0040] Clean the transparent glass substrate ultrasonically with glass cleaner for 30 minutes, then scrub it with a lint-free cloth, then ultrasonically clean it with deionized water for 60 minutes, then ultrasonically clean it with ethanol for 40 minutes, take out the glass substrate and dry it in an oven at 60°C, and perform UV cleaning before use to ensure Wettability of transparent glass; spin-coating Cs by thermal spin coating 2 AgBr 6 Inorganic perovskite film, put 1mmol of cesium bromide, 0.5mmol of bismuth bromide and 0.5mmol of silver bromide in 1ml of DMSO, place on a hot stage at 100°C, stir at 500rpm[r / min] until the solute Dissolve completely to form a transparent mixed precursor solution. Use the spinning high-speed thermal spin coating scheme (spinning parameter: 500rpm[r / min], 30s high-speed par...

Embodiment 2

[0042] Clean the transparent glass substrate ultrasonically with glass cleaner for 30 minutes, then scrub it with a lint-free cloth, then ultrasonically clean it with deionized water for 60 minutes, and then use ethanol to ultrasonically clean it for 40 minutes. Take out the transparent glass and dry it in an oven at 60°C. Wettability of transparent glass; spin coating of CsPbI by thermal spin coating 3 Inorganic perovskite film, put 0.5mmol of cesium iodide and 0.5mmol of lead iodide in 1ml of DMF, place on a hot stage at 30°C, stir at 500rpm[r / min] until the solute is completely dissolved and form a transparent Mix the precursor solution, and use the spinning high-speed thermal spin coating scheme (spinning parameter: 500rpm[r / min], 10s high-speed parameter: 2000rpm[r / min], 30s) to put the precursor hot solution (100℃) on the transparent glass A flat and dense perovskite film is formed on the substrate, and the obtained precursor film is placed on a hot stage for annealing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com