Preparation method of high-entropy ceramic coating

A ceramic coating and high-entropy technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of less research and achieve the effect of simple preparation process, high density and high cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

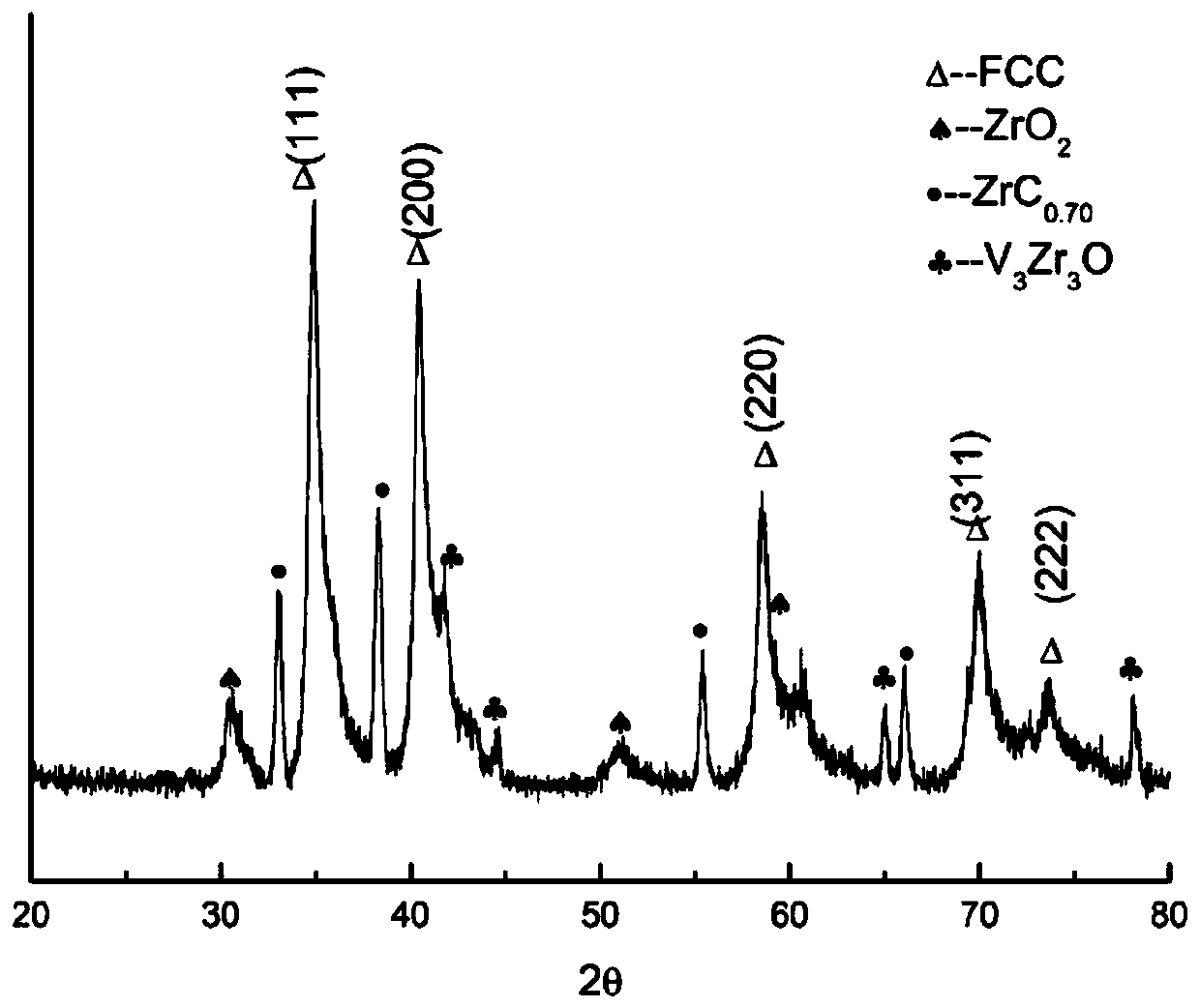

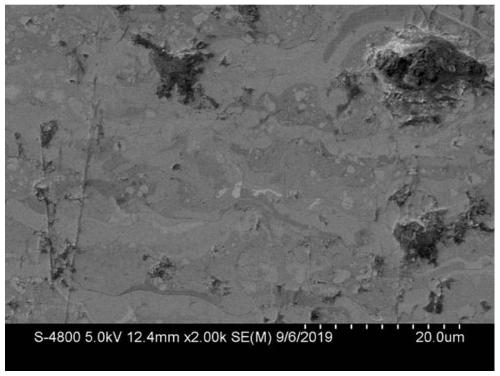

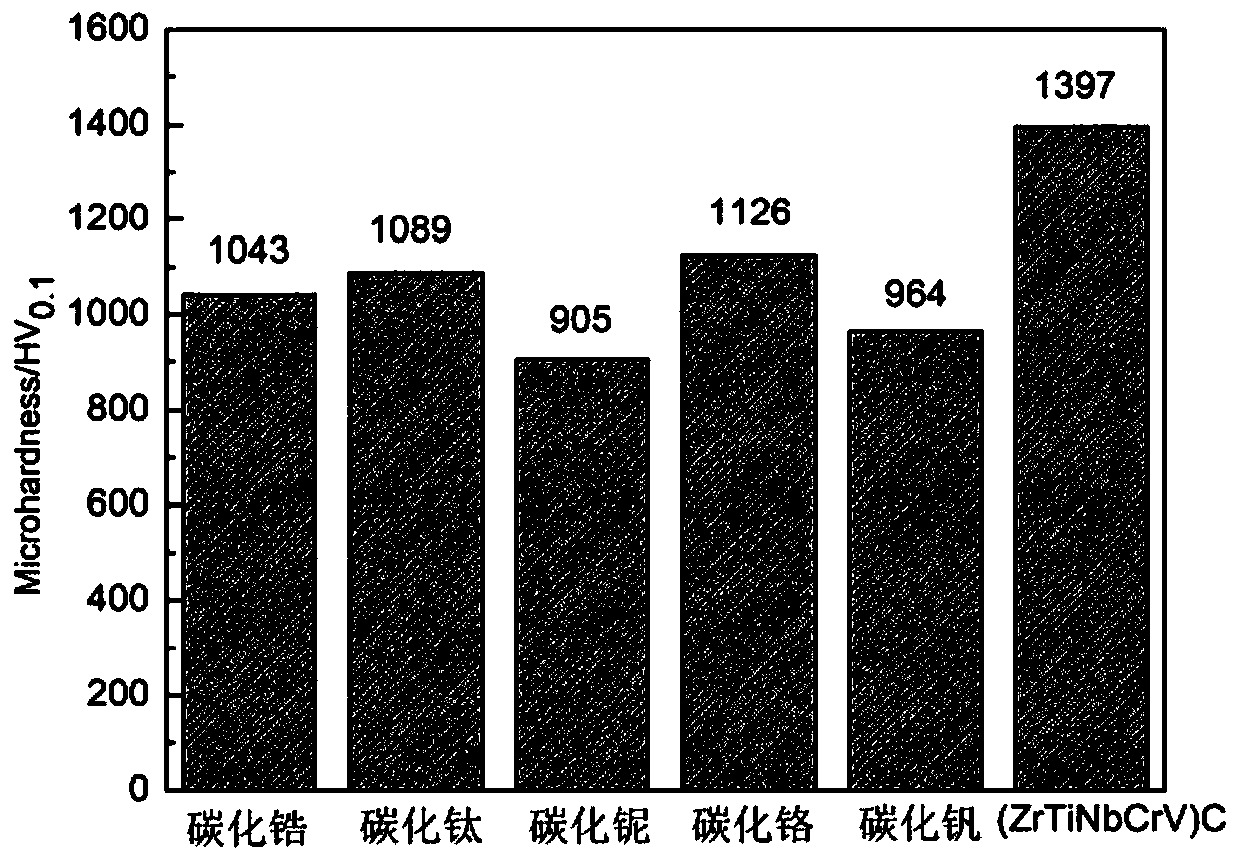

[0036] The first step is to prepare multi-component composite powder for thermal spraying: uniformly mix five kinds of raw material powders zirconium carbide, titanium carbide, niobium carbide, chromium carbide and vanadium carbide with a particle size range of 0.001 micron to 10 micron into a composite powder, Among them, the mass ratio of raw material powder zirconium carbide, titanium carbide, niobium carbide, chromium carbide and vanadium carbide to the total composite powder is 27:15:27:15:16, and then evenly mixed into the binder (methyl cellulose), The binder consumption is that the weight ratio is the above-mentioned composite powder: binder=100:0.1, thus being mixed with multi-element composite powder for thermal spraying;

[0037] The second step, the surface pretreatment of the base material:

[0038] The base material is heat-resistant steel 1Cr18Ni9Ti steel, and the pretreatment method is sandblasting, and then the surface of the 1Cr18Ni9Ti steel base material aft...

Embodiment 2

[0044] The first step is to prepare multi-component composite powder for thermal spraying: uniformly mix five raw material powders ZrC, HfC, TiC, NbC and TaC with a particle size range of 0.001 micron to 10 micron into a composite powder, wherein each raw material The powder accounts for 20% of the total mass ratio of the composite powder, and then evenly mixes into the binder. Sprayed multi-component composite powder;

[0045] The second step, the surface pretreatment of the base material:

[0046] The base material is titanium-aluminum intermetallic compound Ti-48Al-2Cr-2Nb, the pretreatment method is sandblasting, and then the NiCoCrAlYTa bonding layer is sprayed on the surface of the titanium-aluminum intermetallic compound base material after sandblasting;

[0047] The third step, preparation of high-entropy ceramic coating:

[0048] Adopting the method of thermal spraying, spraying the multi-element composite powder for thermal spraying prepared in the above-mentioned ...

Embodiment 3

[0052] Other steps are the same as in Example 1, except that the raw material powder in the first step is six kinds of raw material powders: zirconium carbide, hafnium carbide, tantalum carbide, titanium carbide, niobium carbide and vanadium carbide, which are evenly mixed into composite powder, wherein The mass ratio of raw material powder zirconium carbide, hafnium carbide, tantalum carbide, titanium carbide, niobium carbide and vanadium carbide to the total composite powder is 17:17:17:17:16:16. The properties of the coating thus obtained are close to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com