Catalyst for preparing cyclohexylbenzene by hydroalkylation of benzene, preparation method and application thereof

A technology for the hydrogenation of cyclohexylbenzene and benzene, which is applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of low selectivity, high price, and low catalytic activity of cyclohexylbenzene, and achieve high selectivity , Simple operation, good effect at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

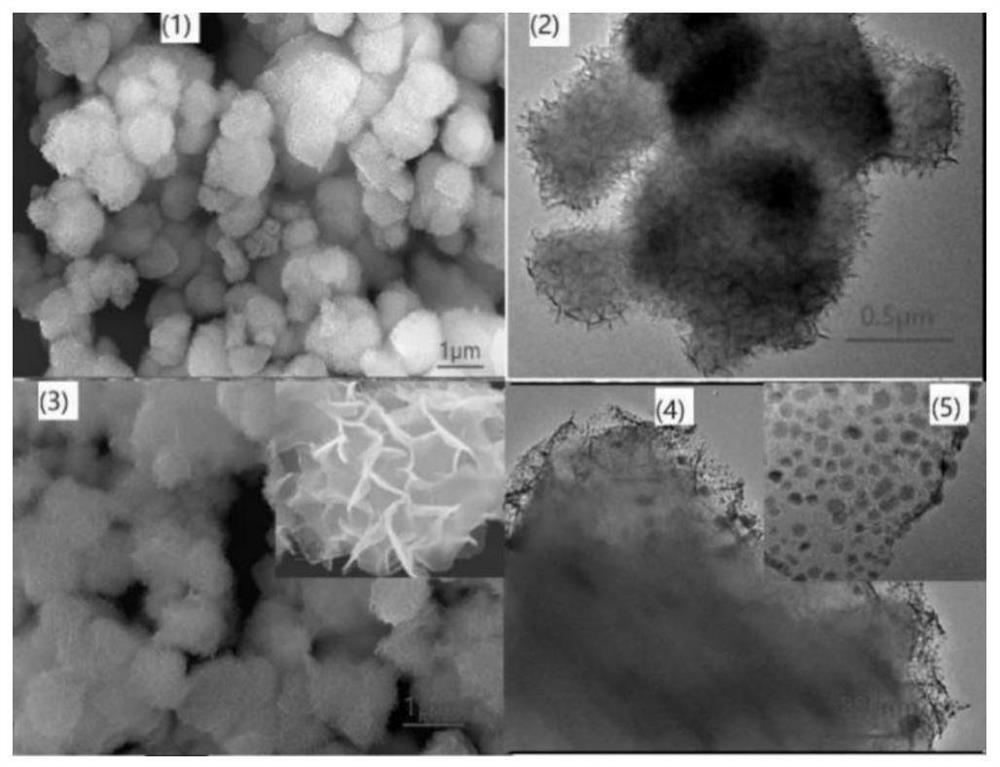

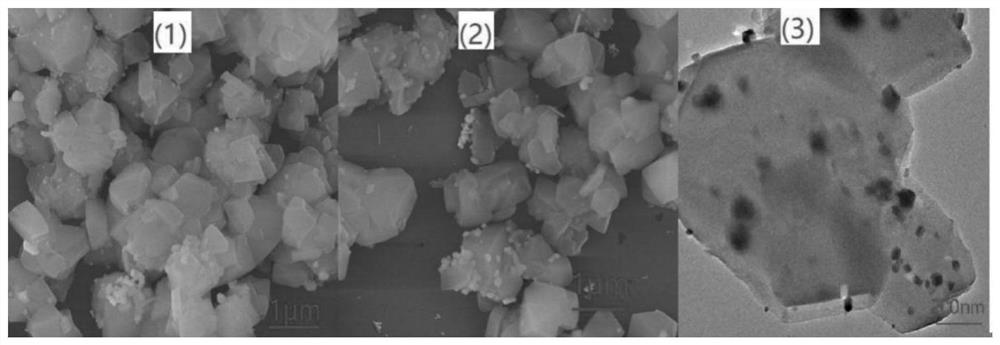

Image

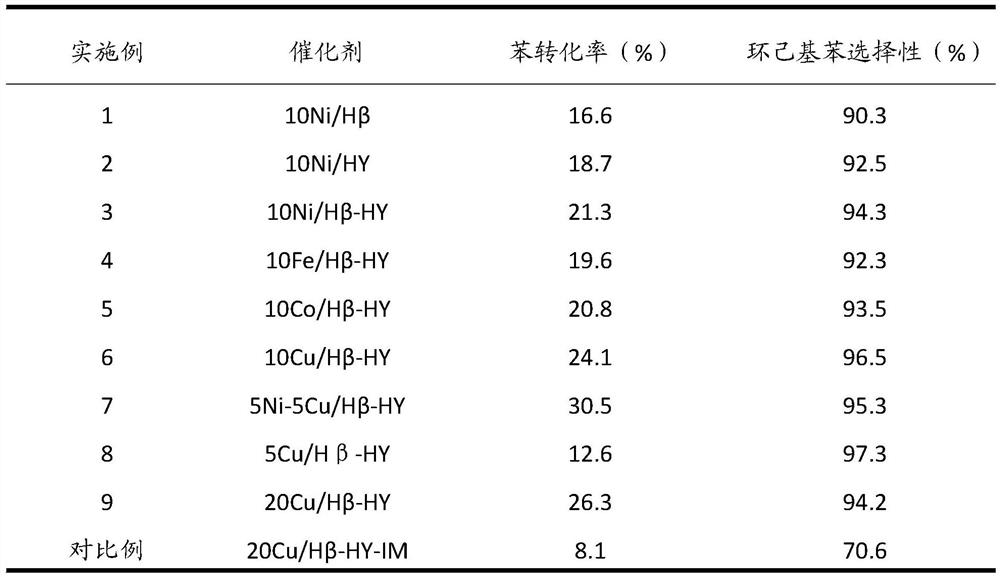

Examples

preparation example Construction

[0029]The present invention also provides a preparation method of the catalyst described in the above technical scheme, which includes the following steps:

[0030](1) Mixing the non-precious metal salt solution, protective agent and complexing agent to obtain a mixed solution;

[0031](2) Add molecular sieve and precipitant to the mixed solution obtained in step (1), and hydrothermally react to obtain a precursor;

[0032](3) The precursor obtained in the step (2) is calcined to obtain a catalyst for the hydroalkylation of benzene to cyclohexylbenzene.

[0033]In the present invention, a non-precious metal salt solution, a protecting agent and a complexing agent are mixed to obtain a mixed solution. In the present invention, the mixing operation of the non-precious metal salt solution, protective agent and complexing agent is not particularly limited, and the technical solution for preparing a mixed solution well known to those skilled in the art may be adopted. In the present invention, the m...

Embodiment 1

[0061]1. Preparation of a catalyst for the hydroalkylation of benzene to cyclohexylbenzene

[0062](1) To 70mL NiCl with a concentration of 31.5mg / mL2Add 30ml of ethylene glycol and 10ml of ethylenediamine to the deionized aqueous solution, and stir at room temperature for 1 hour to obtain a mixed solution;

[0063](2) To the mixed solution obtained in step (1), add 10 g of Hβ molecular sieve, continue to stir at room temperature for 30 minutes, then add 2.0 g of sodium hydroxide and 6.14 g of urea, continue to stir at room temperature for 30 minutes, and then place it in a sealed hydrothermal kettle After the reaction is completed, the reaction kettle is cooled to room temperature, and the resulting product is suction filtered, washed three times with deionized water and 50% ethanol, and then dried at 100°C. 8 hours, get the precursor

[0064](3) The precursor obtained in the step (2) is calcined in a muffle furnace at 500° C. for 4 hours to obtain a catalyst for the hydroalkylation of benz...

Embodiment 2

[0070]According to the method of Example 1, a catalyst for the hydroalkylation of benzene to cyclohexylbenzene was prepared, wherein the molecular sieve was 10g HY molecular sieve, and the finally prepared catalyst was denoted as 10Ni / HY. The same method was used to apply the prepared 10Ni / HY catalyst to benzene hydrogenation to produce cyclohexylbenzene. The specific experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com