Perovskite catalyst and preparation method and application thereof

A catalyst and perovskite technology, applied in the field of perovskite catalysts and their preparation and use, can solve the problems of high requirements for raw materials and reaction conditions, restricting the activity of perovskite, and being unfavorable for large-scale promotion, and achieving easy mass production. The effect of production, overcoming adverse effects, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The first aspect of the present invention provides a kind of preparation method of perovskite catalyst, it comprises the following steps:

[0049] The raw material solution is adsorbed by a template agent to obtain a catalyst precursor;

[0050] heat-treating the catalyst precursor to obtain a doped perovskite compound;

[0051] Dissolving the complex at least partially, through the dissolution to at least partially remove the B element on the surface of the complex; wherein,

[0052] The doped perovskite compound has a composition of the following formula (I):

[0053] A 1-x B x CO 3 (I)

[0054] B means doped in ACO 3 The metal elements in the type perovskite structure, the A element is selected from rare earth metals, the B element is selected from alkaline earth metals, and C is selected from transition metals, 0<x<1.

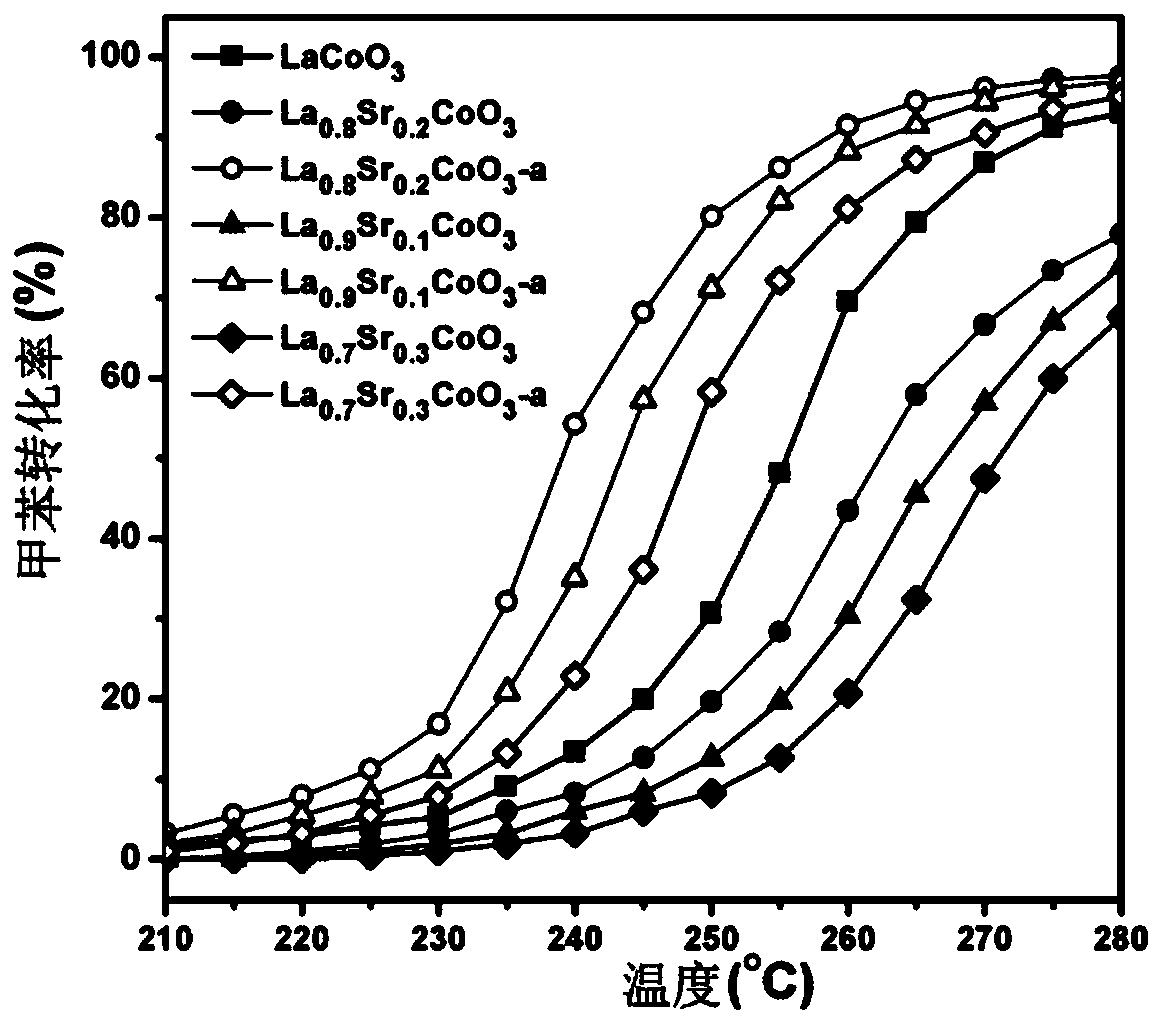

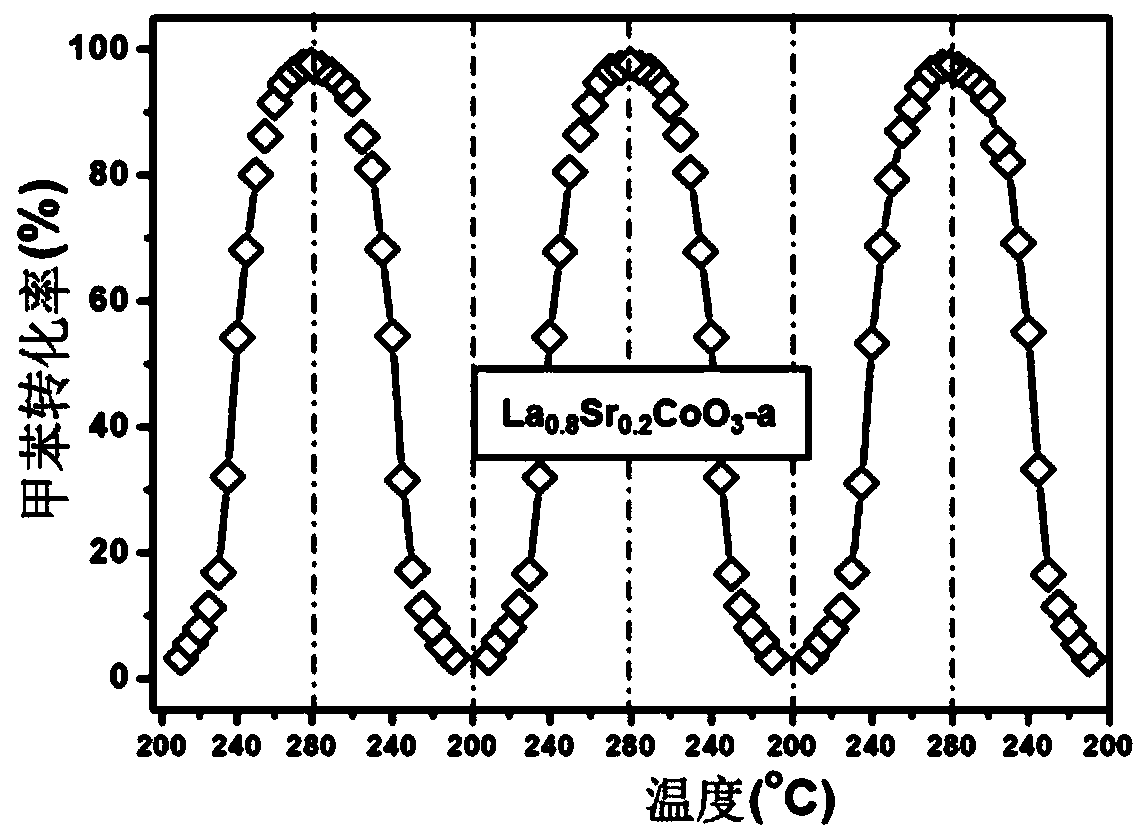

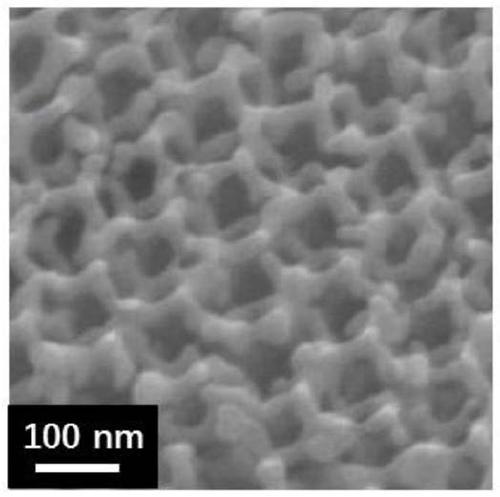

[0055] Compared with the common doped perovskite catalyst, the perovskite catalyst of the present invention overcomes the adverse effect of ...

Embodiment 1

[0096] Step 1: Weigh 10.39g of lanthanum nitrate, 1.27g of strontium nitrate, and 8.73g of cobalt nitrate in 18mL of deionized water, and stir at room temperature for 2 hours;

[0097] Step 2: adding 2 g template polymethyl methacrylate (PMMA) microspheres into the solution obtained in Step 1 and soaking for 10 h;

[0098] Step 3: Filter the solution in Step 2, and dry the remaining solid at room temperature for 24 hours;

[0099] Step 4: Place the dry powder obtained in Step 3 in a tube furnace, raise it from room temperature to 300 °C at a rate of 1 °C / min in a nitrogen atmosphere, and keep it at this temperature for 3 hours, then lower it to room temperature, switch to an air atmosphere at a temperature of 1 °C / min ramp up to 300°C and hold at this temperature for 1h, and finally rise to 900°C and hold at this temperature for 4h. After cooling, the obtained sample is La 0.8 Sr 0.2 CoO 3 .

[0100] Step 5: La obtained from Step 4 0.8 Sr 0.2 CoO 3 The powder was treat...

Embodiment 2

[0104] Step 1: Weigh 11.69g of lanthanum nitrate, 0.64g of strontium nitrate, and 8.73g of cobalt nitrate in 18mL of deionized water, and stir at room temperature for 2 hours;

[0105] Step 2: adding 2 g template polymethyl methacrylate (PMMA) microspheres into the solution obtained in Step 1 and soaking for 10 h;

[0106] Step 3: Filter the solution in Step 2, and dry the remaining solid at room temperature for 24 hours;

[0107] Step 4: Place the dry powder obtained in Step 3 in a tube furnace, raise it from room temperature to 300 °C at a rate of 1 °C / min in a nitrogen atmosphere, and keep it at this temperature for 3 hours, then lower it to room temperature, switch to an air atmosphere at a temperature of 1 °C / min ramp up to 300°C and hold at this temperature for 1h, and finally rise to 900°C and hold at this temperature for 4h. After cooling, the obtained sample is La 0.9 Sr 0.1 CoO 3 .

[0108] Step 5: La obtained from Step 4 0.9 Sr 0.1 CoO 3 The powder was treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com