Ancient building transparent fireproof coating and preparation method thereof

A technology for fire-resistant coatings and ancient buildings, applied in fire-resistant coatings, epoxy resin coatings, chemical instruments and methods, etc., can solve problems such as affecting production efficiency and difficult cleaning of filter devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] As shown in Tables 1 to 2, a transparent fireproof coating for ancient buildings is characterized in that: calculated by weight, it includes 57.2 kg of formaldehyde, 6 kg of melamine, 12.8 kg of urea, 10 kg of formic acid, 0.17 kg of basic magnesium carbonate, and triethanolamine 4.3kg, epoxy resin 24.7kg, 1,2-butanediol glycidyl ether 12.5kg, dibromoneopentyl glycol 6.3kg, pentaerythritol 5.6kg, polyphosphoric acid 22.6kg, dibutyl phthalate 2kg, Methanol 18kg, n-butanol 12.5kg, cyclohexane 4kg, ethylene glycol butyl ether 2kg, 10kg of 10% sodium hydroxide and ammonium persulfate 2kg.

[0037] Table 1 Formula of component A of transparent fireproof coating for ancient buildings

[0038] material name Classification mass kg formaldehyde carbon source 57.2 Melamine Gas source 6 urea carbon source 12.8 Triethanolamine penetration aid 4.3 Basic magnesium carbonate catalyst 0.17 formic acid PH regulator 3 penta...

Embodiment 2

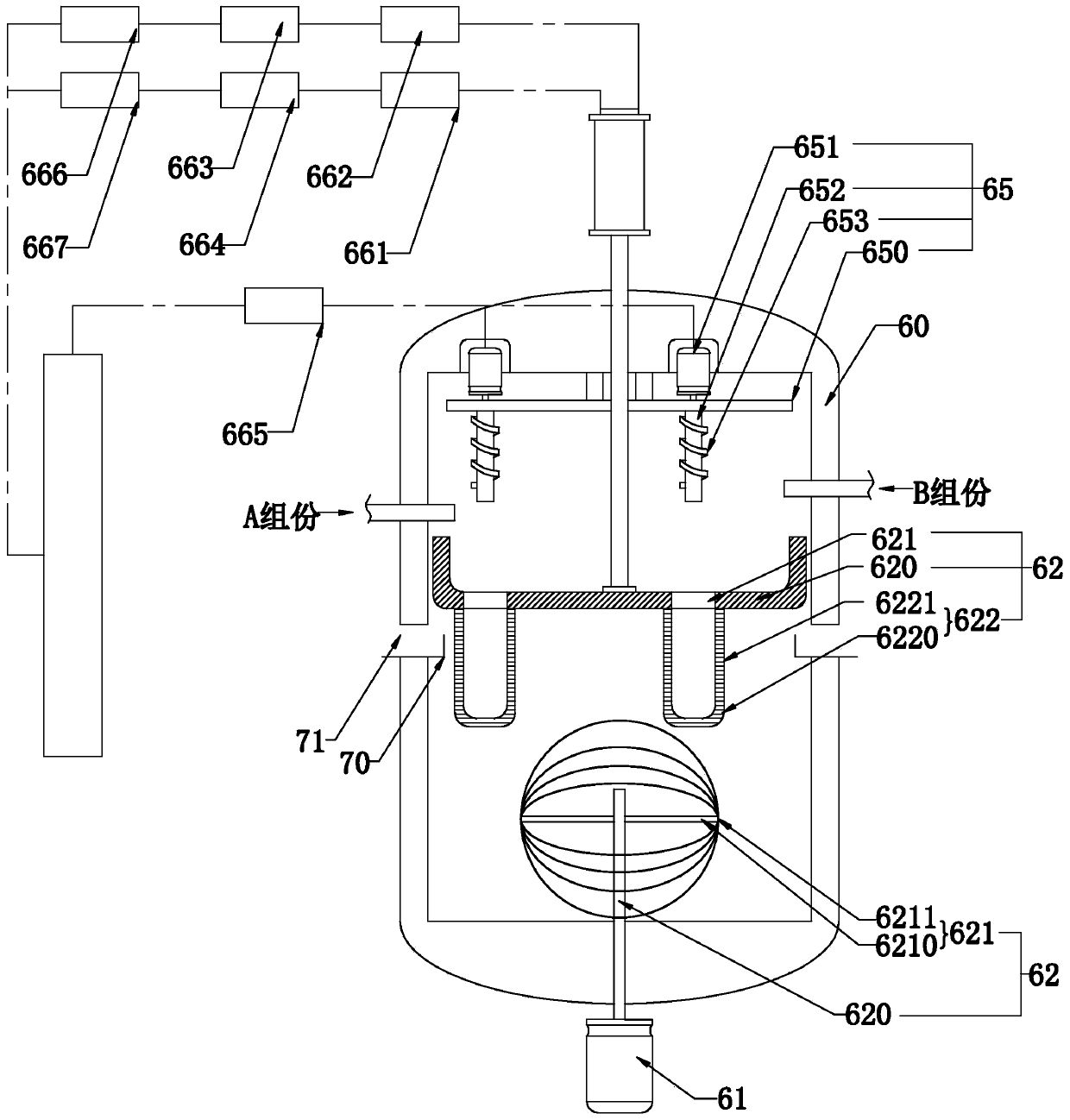

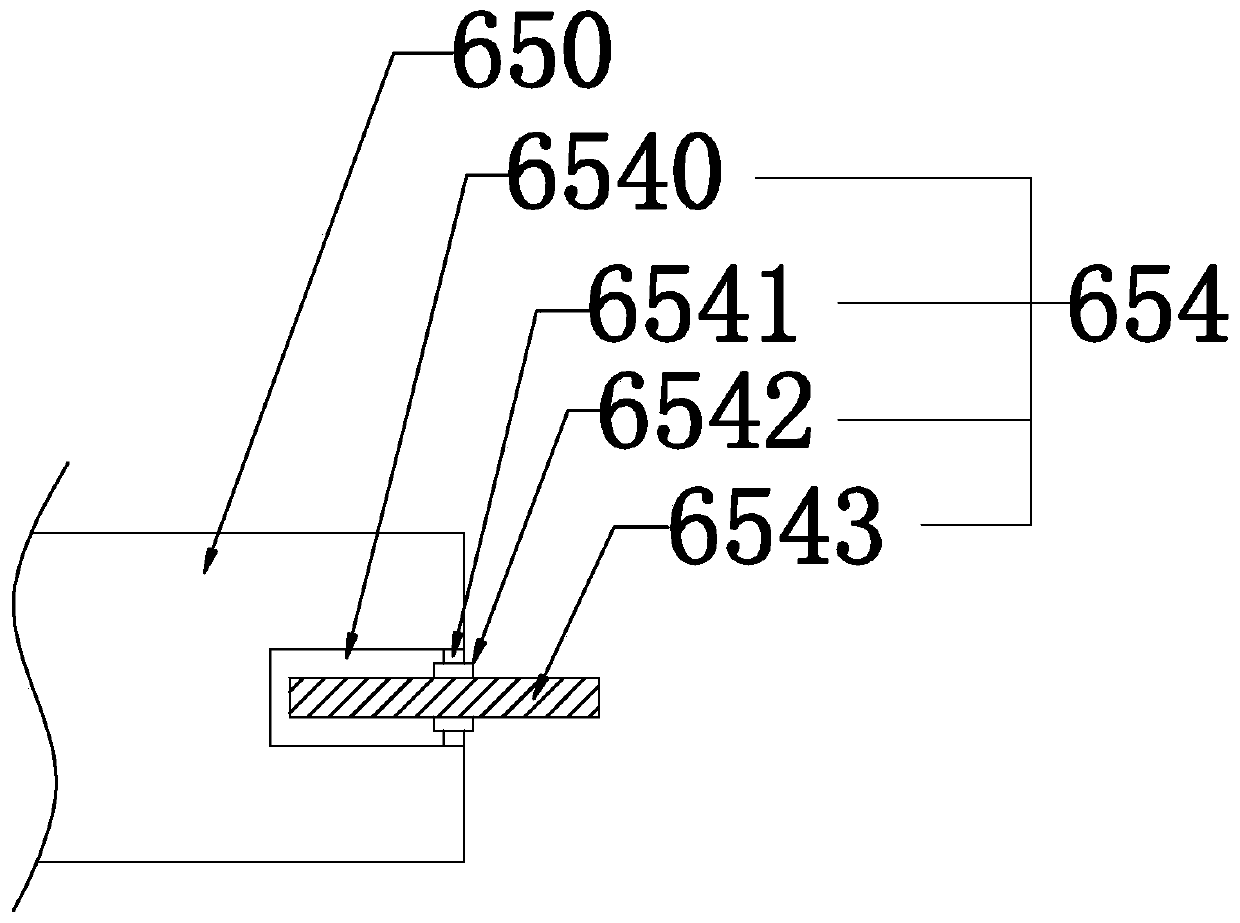

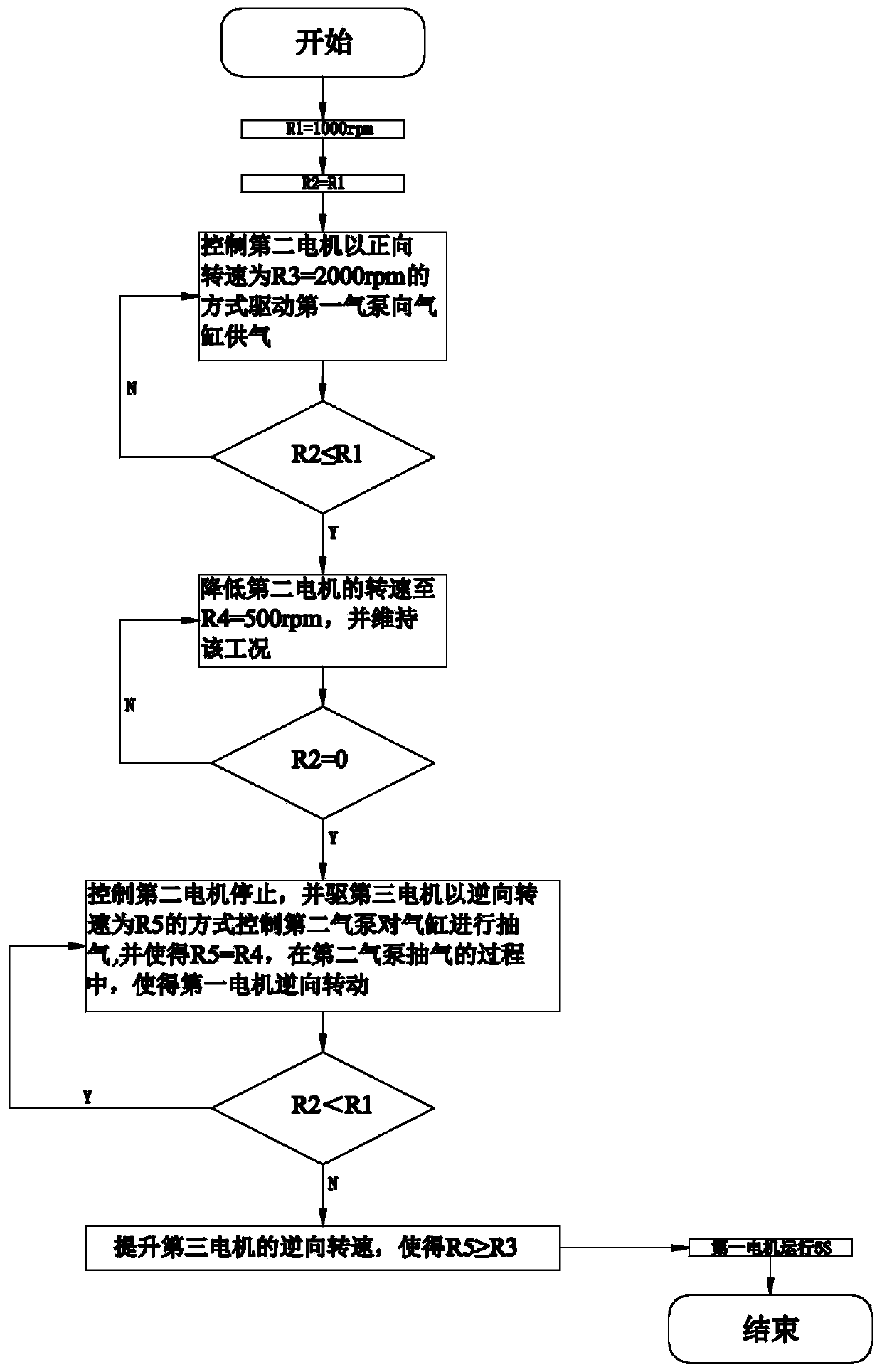

[0043] Such as Figure 1 ~ Figure 3 Shown, the present invention discloses a kind of preparation method of ancient building transparent fireproof coating, in the specific embodiment of the present invention, the preparation method of described A component:

[0044] 1.1. Accurately weigh 57.2kg of formaldehyde and add it to the reactor from the feeding port of 1# reactor (or start the vacuum pump to pump it into the reactor), add 0.17kg of basic magnesium carbonate at the same time, press the stirring button to start stirring, and start the circulation cooling water system;

[0045] 1.2. After the 1# reactor was stirred for 5 minutes, add 0.7kg of 50% formic acid solution into the reactor, and after stirring for 5 minutes, open the outlet valve of the reactor, release a little liquid, and measure the pH value of the liquid in the reactor with PH test paper , if the pH value is greater than 6.5, add an appropriate amount of 50% formic acid solution, continue to stir for 3 to 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com