Porous impact-resistant tpu composite pressure sensing material, preparation method and application

A technology of sensing materials and impact resistance, applied in the direction of measuring force, instruments, measuring devices, etc., can solve the complex preparation process of three-dimensional porous conductive polymer composite materials, weak bonding force between conductive filler and polymer substrate, energy absorption and impact resistance Poor performance and other problems, to achieve the effect of excellent protection, good mechanical properties, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

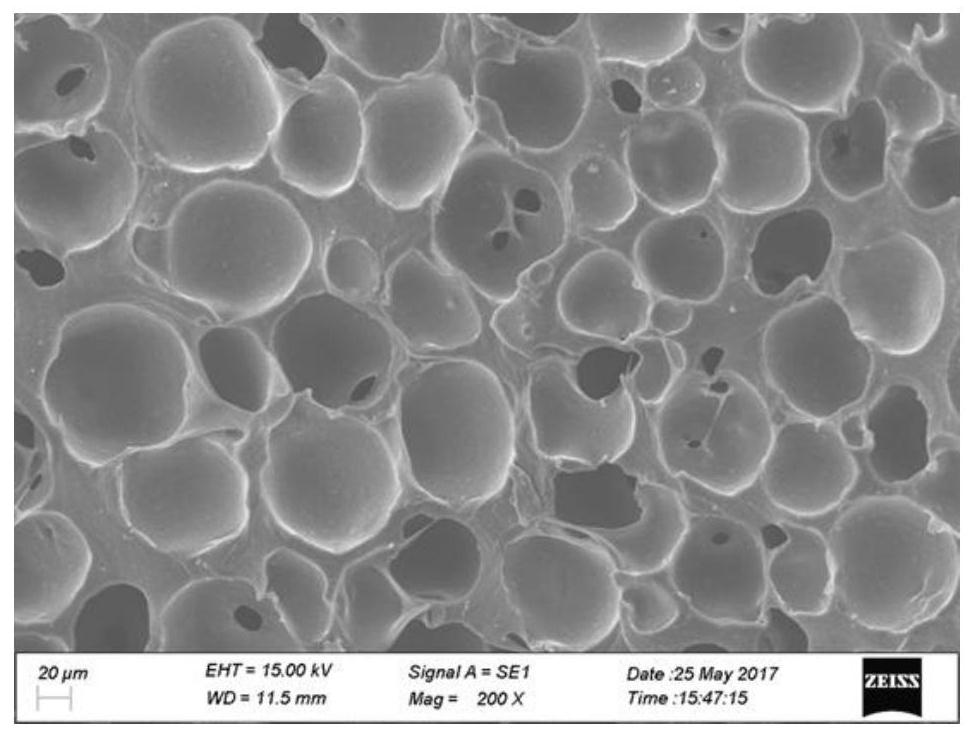

[0065] Example 1. Preparation of porous impact-resistant TPU composite stress-sensing material

[0066] (1) Dissolve 10g of TPU particles in 90mL of N'N-dimethylacetamide, mix well, then add 0.2g of carbon nanotubes, and disperse evenly to obtain a mixed solution;

[0067] (2), placing the mixed solution of step (1) in a desiccator filled with water at the bottom, sealing the steam to induce phase separation for 5 days, and obtaining the formed TPU composite pressure sensing material;

[0068] (3), the formed TPU composite pressure sensing material in step (2) was washed twice with 50 mL of ethanol, then washed twice with 100 mL of distilled water, and then the washed TPU composite pressure sensing material was frozen in a -80°C refrigerator for 12 hours , and then placed in a -72°C freeze dryer for 72 hours to obtain a freeze-dried porous impact-resistant TPU composite pressure sensing material.

[0069] In this embodiment, the added mass of conductive material carbon nanotu...

Embodiment 2

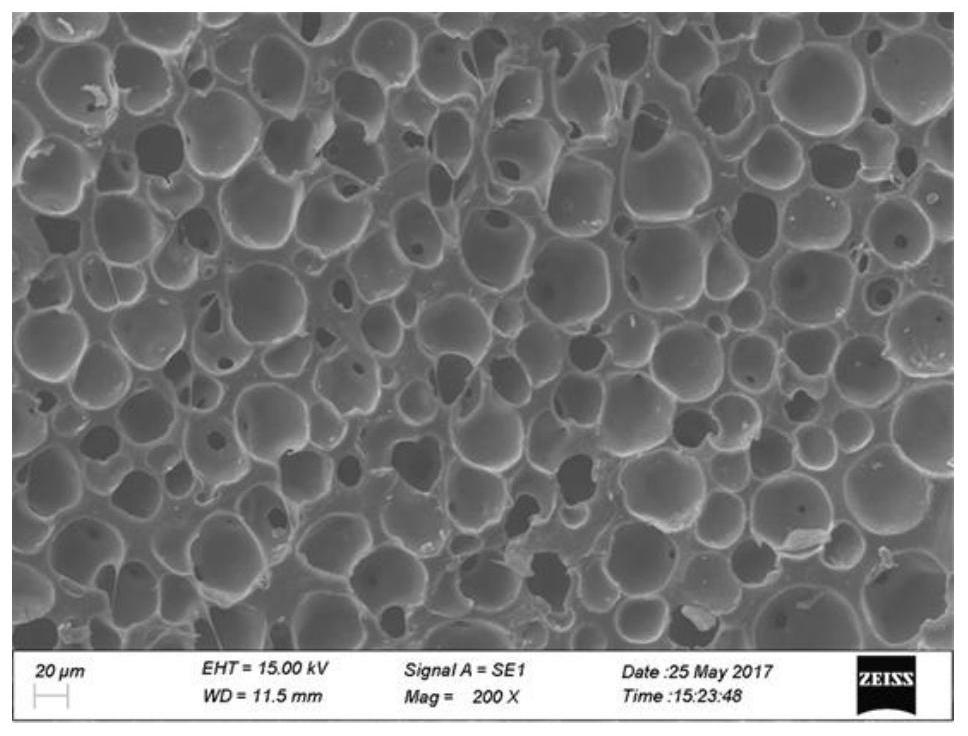

[0070] Example 2. Preparation of porous impact-resistant TPU composite stress-sensing material

[0071] (1) Dissolve 30g of TPU particles in 70mL of N'N-dimethylacetamide, mix well, then add 2.4g of carbon nanotubes, and disperse evenly to obtain a mixed solution;

[0072] (2), placing the mixed solution of step (1) in a desiccator filled with water at the bottom, and sealing the steam to induce phase separation for 10 days to obtain a molded TPU composite pressure sensing material;

[0073] (3), the formed TPU composite pressure sensing material in step (2) was washed twice with 50 mL of ethanol, then washed twice with 100 mL of distilled water, and then the washed TPU composite pressure sensing material was frozen in a -80°C refrigerator for 12 hours , and then placed in a -72°C freeze dryer for 72 hours to obtain a freeze-dried porous impact-resistant TPU composite pressure sensing material.

[0074] In this embodiment, the added mass of conductive material carbon nanotube...

Embodiment 3

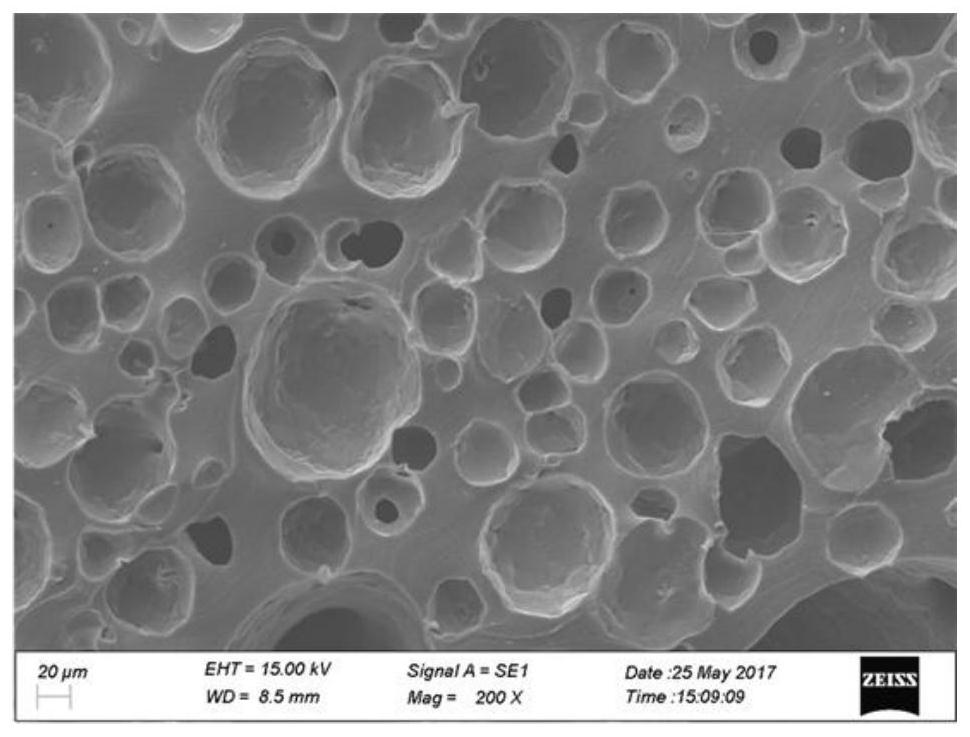

[0075] Example 3, preparation of porous impact-resistant TPU composite stress sensing material

[0076] The basic scheme is the same as in Example 2, the difference is that in the step (1), 3g of carbon nanotubes are added, that is, the quality of the added carbon nanotubes is 10wt% of the TPU mass;

[0077] In the step (2), the closed steam induces phase separation for 15 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com