A method for improving the surface quality of boron-containing steel continuous casting slab

A surface quality, boron steel technology, applied in metal rolling and other directions, can solve the problems of damage to slab quality, low mold slag viscosity, high production cost, optimize heating process and rolling temperature, avoid oxide hazards, improve The effect of the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] For a low-carbon boron-containing steel AQ0940K1, the weight percentages of other components except iron and impurities are shown in Table 1:

[0035] Table 1. Main chemical composition of AQ0940K1 steel (wt / %)

[0036] C Si mn P S Al Ti B N 0.0483 0.0056 0.1984 0.0155 0.0063 0.0419 0.0191 0.0014 0.0028

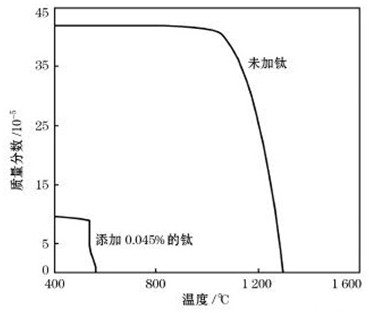

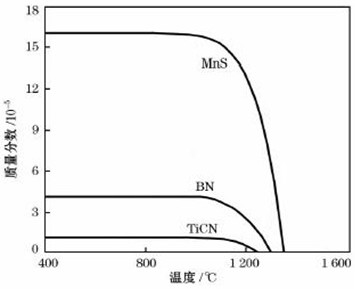

[0037](1) When the low-carbon boron-containing steel AQ0940K1 is produced, the composition of molten steel in the smelting process is controlled according to Table 1; when the Al element is added to molten steel for ≥ 3 minutes and the dissolved oxygen in molten steel is ≤ 5ppm, titanium alloy is added, and the addition of Ti element in molten steel The amount is calculated according to the following formula:

[0038] Ti%=3.43×N%+1.5×S%=3.43×0.0028+1.5×0.0063=0.0191;

[0039] Mn / S in molten steel=0.1984 / 0.0063=31.5.

[0040] (2) Calculation according to the casting speed conditions of the continuous casting machine: ①Control the t...

Embodiment 2

[0047] For a high-carbon boron-containing steel IS5120B4, the weight percentages of other components except iron and impurities are shown in Table 2:

[0048] Table 2. Main chemical composition of IS5120B4 steel (wt / %)

[0049] C Si mn P S Al Ti B N 0.34 0.22 0.65 0.0145 0.0053 0.032 0.0185 0.0015 0.0031

[0050] (1) When the high-carbon boron-containing steel IS5120B4 is produced, the composition of the molten steel in the smelting process is controlled according to Table 2; when the Al element is added to the molten steel for ≥ 3 minutes and the dissolved oxygen in the molten steel is ≤ 5ppm, titanium alloy is added, and the addition of Ti element in the molten steel The amount is calculated according to the following formula:

[0051] Ti%=3.43×N%+1.5×S%=3.43×0.0031+1.5×0.0053=0.0186;

[0052] Mn / S in molten steel=0.65 / 0.0053=122.6.

[0053] (2) Calculation according to casting speed conditions: ①Control the solidification shell thickne...

Embodiment 3

[0059] For a medium-carbon boron-containing steel XO878169, the weight percentages of other components except iron and impurities are shown in Table 3:

[0060] Table 3. Main chemical composition of XO878169 steel (wt / %)

[0061] C Si mn P S Al Ti B N 0.12 0.06 1.15 0.01 0.002 0.055 0.0133 0.0011 0.003

[0062] (1) During the production of medium-carbon boron-containing steel XO878169, the molten steel composition in the smelting process is controlled according to Table 3; when the Al element is added to the molten steel for ≥ 3 minutes and the dissolved oxygen in the molten steel is ≤ 5ppm, titanium alloy is added, and the Ti element in the molten steel is added The amount is calculated according to the following formula:

[0063] Ti%=3.43×N%+1.5×S%=3.43×0.003+1.5×0.002=0.0133;

[0064] Mn / S in molten steel=1.15 / 0.002=575.

[0065] (2) Calculation according to the casting speed conditions of the continuous casting machine: ①Control the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com